Rozwiązania do uprzemysłowienia wytwarzania addytywnego

Solidne portfolio oprogramowania firmy Siemens umożliwia realizację całego procesu wytwarzania addytywnego, od projektu do produkcji. Czytaj dalej, aby dowiedzieć się, czego wymaga uprzemysłowienie wytwarzania addytywnego.

Projektowanie pod wytwarzanie addytywne

Proces wytwarzania addytywnego wysokiej jakości rozpoczyna się zawsze od projektu. Wytwarzanie addytywne zapewnia możliwość produkowania bardzo złożonych projektów z takimi cechami jak zoptymalizowane powierzchnie i struktury kratownicowe. Nasze rozwiązania do wytwarzania addytywnego umożliwiają projektowanie i drukowanie złożonych geometrii w skali.

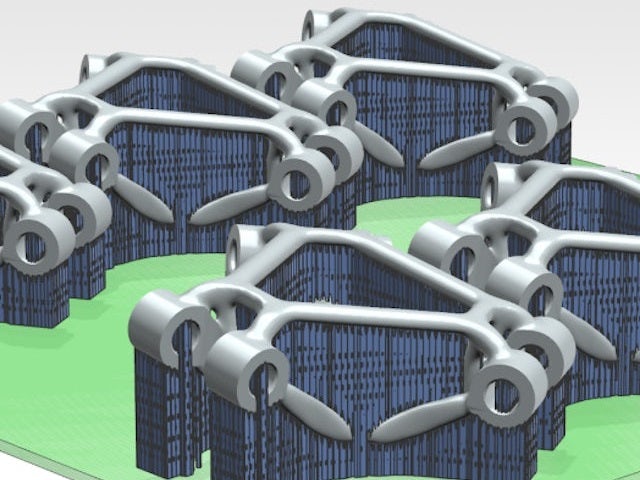

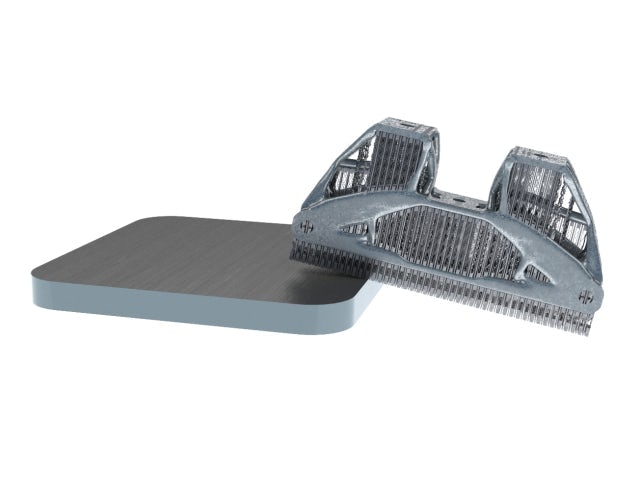

Przygotowanie tacy wydruku

Uzyskanie efektywnych wyników wytwarzania addytywnego wysokiej jakości wymaga odpowiedniej konfiguracji. Zintegrowane narzędzia przygotowania wydruku w oprogramowaniu NX pomagają w umieszczaniu, ustawianiu i podpieraniu części na tacy podporowej w najbardziej efektywny sposób.

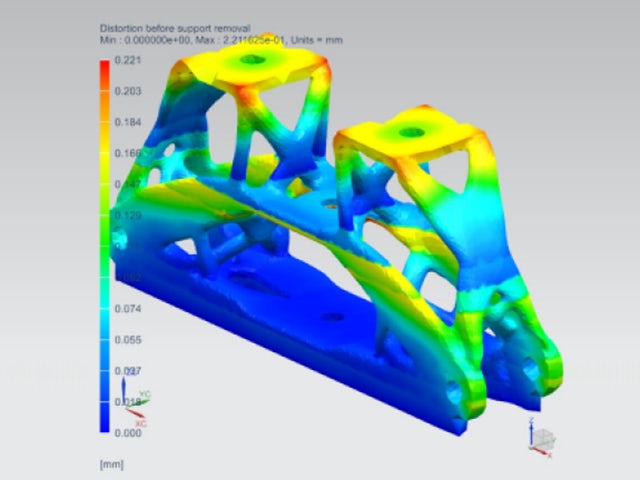

Symulacja wydruku

Symulacja procesu drukowania może pomóc w generowaniu wysokiej jakości wydruków 3D na dużą skalę. Od optymalizacji orientacji wydruku po optymalizację ścieżki osadzania w mezoskali: oprogramowanie NX oferuje narzędzia zapewniające udany wydruk już za pierwszym razem.

Łączność z maszynami

Korzystaj z funkcji łączności w oprogramowaniu NX firmy Siemens obsługujących najszerszą gamą sprzętu do drukowania 3D. Niektóre z systemów obejmują systemy płaszczyznowego złoża proszkowego, systemy osadzania filamentowego, systemy wielomateriałowe i systemy wieloosiowe.

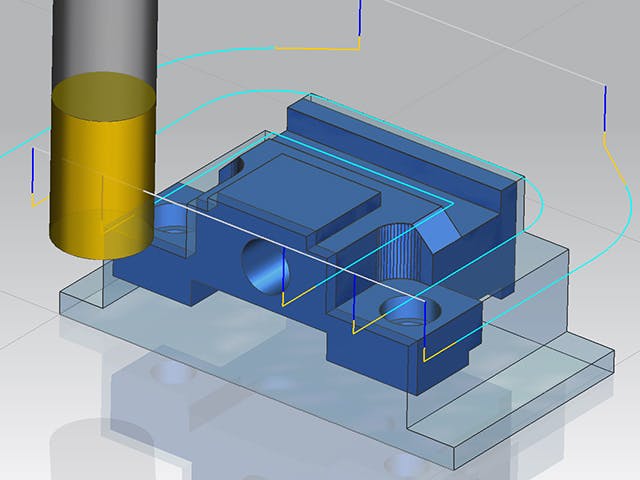

Przetwarzanie po wydrukowaniu

Uprzemysłowienie drukowania 3D wymaga niezawodnego oprogramowania do przetwarzania końcowego. Drukowanie nie jest ostatnim krokiem w procesie wytwarzania addytywnego. Usuwanie proszku, usuwanie części z tacy wydruku i przetwarzanie końcowe po wydruku stanowią aspekty pełnego procesu wytwarzania addytywnego. Wszystkie z nich są częścią naszego zestawu rozwiązań do wytwarzania addytywnego.

Zarządzanie procesami

Zmaksymalizowanie wydajności wytwarzania addytywnego wymaga sprawnego zarządzania procesem. Obejmuje to proces od zamówienia do wysyłki, a także zarządzanie materiałami i harmonogramowanie maszyn. Oferujemy rozwiązania dla firm każdej wielkości, aby zapewnić maksymalną wydajność całego procesu wytwarzania addytywnego, maksymalizując w ten sposób zwrot z inwestycji w tę technologię.

LimaCorporate

Projektowanie implantów przy użyciu druku 3D i oprogramowania NX

Firma:LimaCorporate

Lokalizacja:Villanova, San Daniele del Friuli, Włochy

Siemens Software:NX

Wielkość:Medium

Poznaj powiązane produkty NX do obsługi wytwarzania addytywnego

Zobacz nasze profesjonalne rozwiązania do praktycznych, przemysłowych zastosowań projektowania pod kątem wytwarzania addytywnego.