W jaki sposób można produkować wysoce precyzyjne, wysokiej jakości, dostosowane do potrzeb klienta i zrównoważone komponenty na czas i na dużą skalę — a wszystko to przy jednoczesnej poprawie ogólnej produktywności i rentowności?

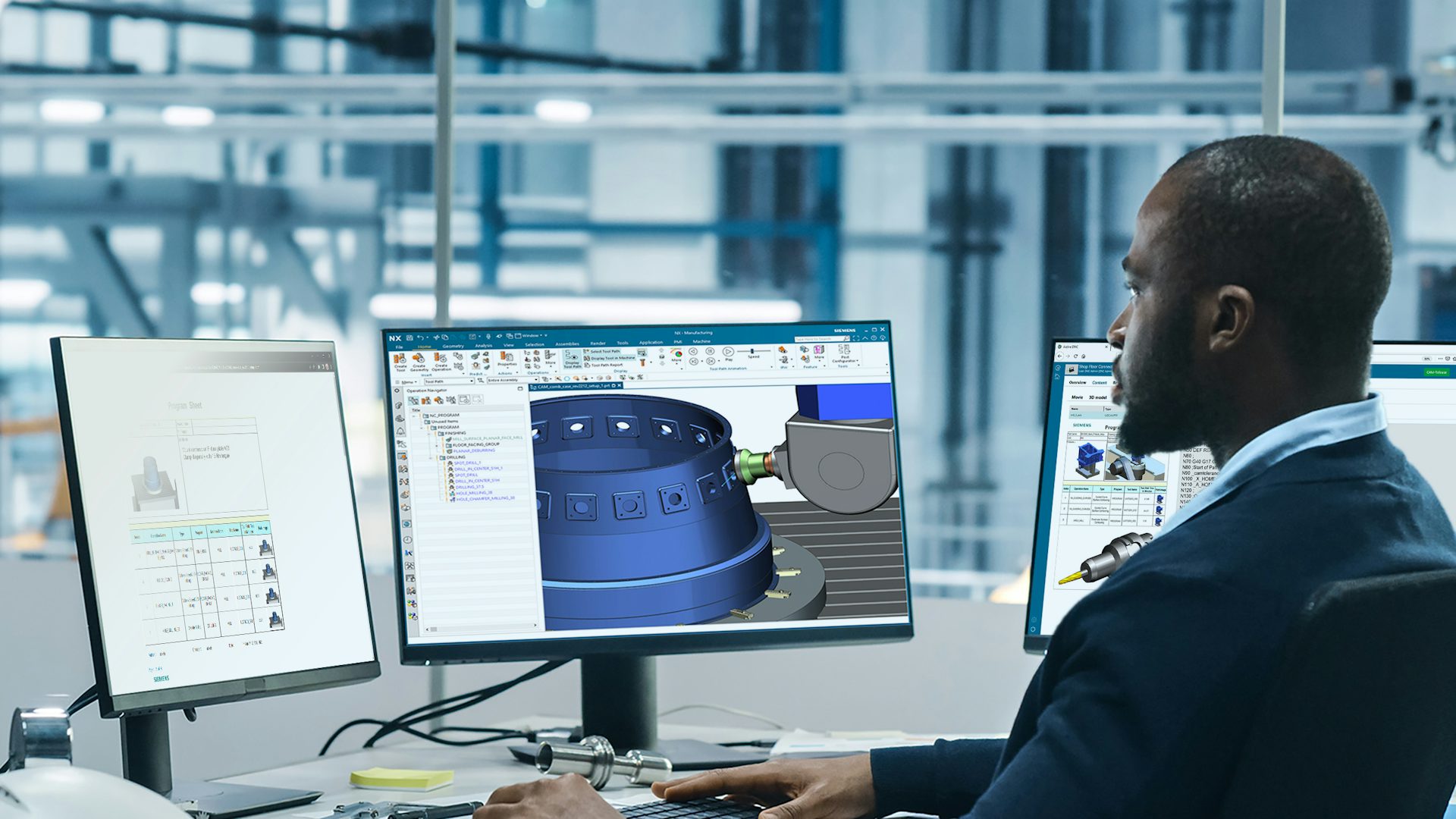

Wdrożenie zintegrowanego oprogramowania do produkcji narzędzi i części. Zautomatyzuj i bezproblemowo połącz projektowanie, produkcję i operacje w cyfrowym warsztacie mechanicznym, korzystając ze sprawdzonego, wydajnego pakietu narzędzi i rozwiązań programowych.