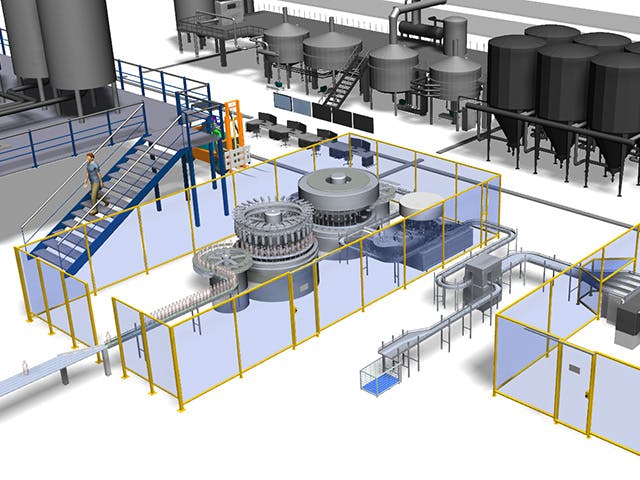

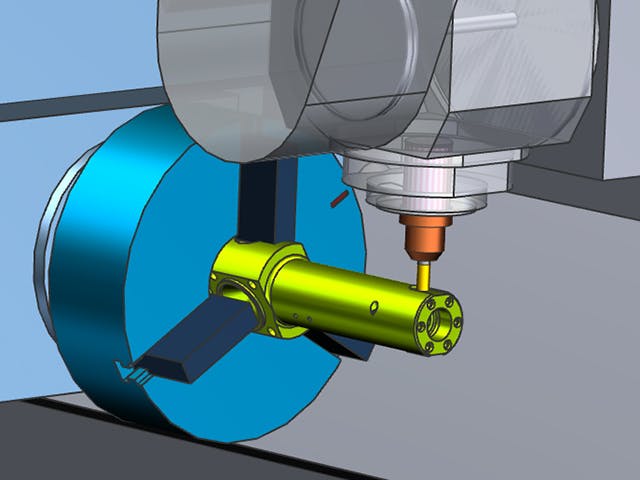

Produkcja cyfrowa to wykorzystanie zintegrowanego, komputerowego systemu składającego się z symulacji, wizualizacji 3D, narzędzi analitycznych i narzędzi do współpracy w celu jednoczesnego tworzenia definicji produktów i procesów produkcyjnych. Produkcja cyfrowa wyewoluowała z inicjatyw produkcyjnych, takich jak projektowanie pod kątem możliwości produkcyjnych (DFM), produkcja zintegrowana komputerowo (CIM), elastyczna produkcja i produkcja oszczędna, które podkreślają potrzebę wspólnego projektowania produktów i procesów.

Wiele długoterminowych korzyści płynących z zarządzania cyklem życia produktu (PLM) nie może zostać osiągniętych bez kompleksowej cyfrowej strategii produkcji. Produkcja cyfrowa jest kluczowym punktem integracji między PLM a aplikacjami i sprzętem na hali produkcyjnej, umożliwiając wymianę informacji związanych z produktem między grupami projektowymi i produkcyjnymi. To dostosowanie pozwala firmom produkcyjnym osiągnąć cele związane z czasem wprowadzenia produktu na rynek i wolumenem, a także uzyskać oszczędności kosztów poprzez ograniczenie kosztownych zmian na dalszych etapach produkcji.

Powiązane produkty: Tecnomatix | NX | Solid Edge