Jakie strategie mogą zastosować inżynierowie lotnictwa i kosmonautyki, aby przyspieszyć czas projektowania, osiągnąć cele w zakresie wydajności i zapewnić sprawne wprowadzenie do eksploatacji?

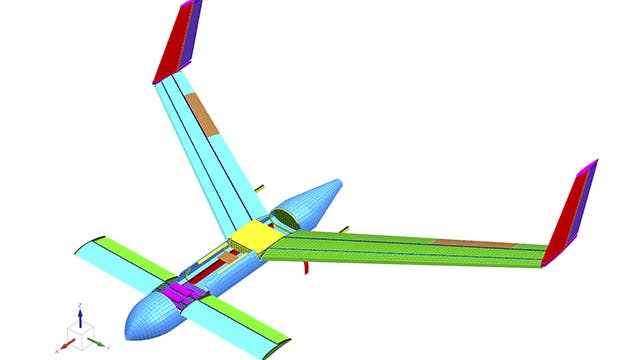

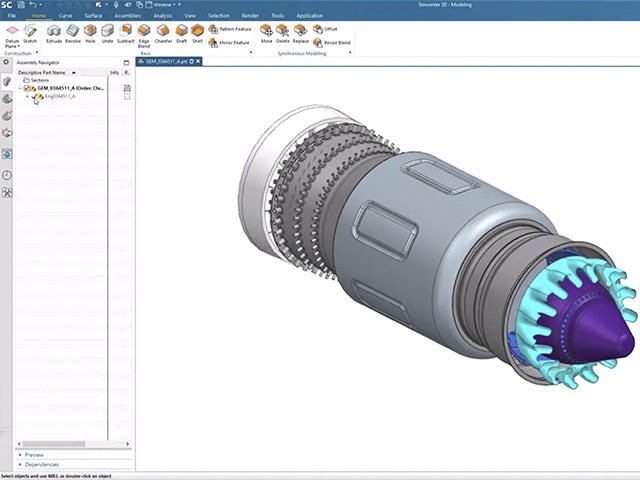

Wdrażaj zintegrowaną strategię symulacji i testowania oraz korzystaj z oprogramowania do symulacji lotniczej, aby napędzać transformację cyfrową, rozbijać silosy między branżami i uzyskiwać wcześniejszy wgląd w wydajność produktów w zakresie konstrukcji, aerodynamiki, integracji wirtualnej i nie tylko.