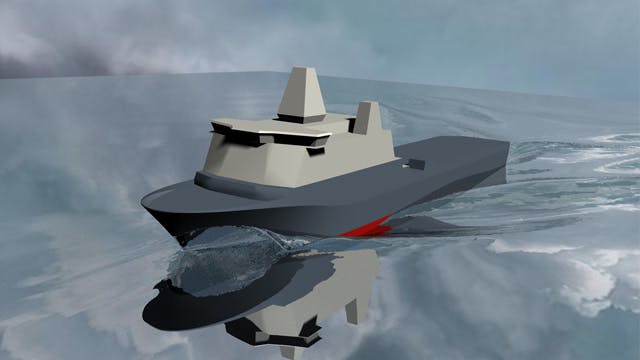

CFD(전산 유체 역학), 특히 유체 역학 시뮬레이션은 선박 설계 목표치를 충족하고 복잡한 작동 시나리오에서 실제 성능을 예측하는 데 핵심적 역할을 합니다. 그러나 시뮬레이션 시간은 모델 크기와 필요한 물리적 특성의 복잡성에 따라 길어질 수 있습니다. 본 온디맨드 웨비나에서 최신 해양 CFD 기술이 복잡한 시나리오를 신속하게 분석하고 대체 설계를 탐색하는 데 어떻게 도움이 되는지 알아보십시오.

조선 설계 프로세스를 간소화하는 방법

엔지니어링 시뮬레이션의 새로운 개발로 생산성이 크게 향상되면서 조선 설계 프로세스가 간소화되고 있습니다. 고급 다중 물리학 및 모션 모델과 결합된 다중 메시 시퀀싱 방법, 적응형 메시 개선 등으로 CFD 시뮬레이션에서 수동 작업을 제거하고 조선 설계 프로세스의 속도를 높일 수 있습니다.

CFD 시뮬레이션 소프트웨어를 활용하여 생산성 향상

시뮬레이션 설정 및 실행에 오랜 시간이 걸려 어려움을 겪고 계신가요? 이제 문제를 해결할 수 있습니다. 메싱 방법 가속화, 설계 스윕 자동화 등 CFD 시뮬레이션 소프트웨어의 향상된 기능을 CFD 프로세스에 적용해 시뮬레이션 시간을 현저하게 줄이고 생산성을 크게 높일 수 있습니다.

배치 시뮬레이션을 사용하여 정확도 높은 선박 설계 테스트

템플릿을 사용하면 설정 시간을 크게 줄일 수 있습니다. 또한 배치 시뮬레이션을 수행하여 다양한 설계를 높은 정확도로 테스트할 수 있습니다. 본 웨비나에서는 Simcenter STAR-CCM+를 사용한 여러 예시를 보여줍니다.

지금 웨비나에서 자세히 알아보십시오.