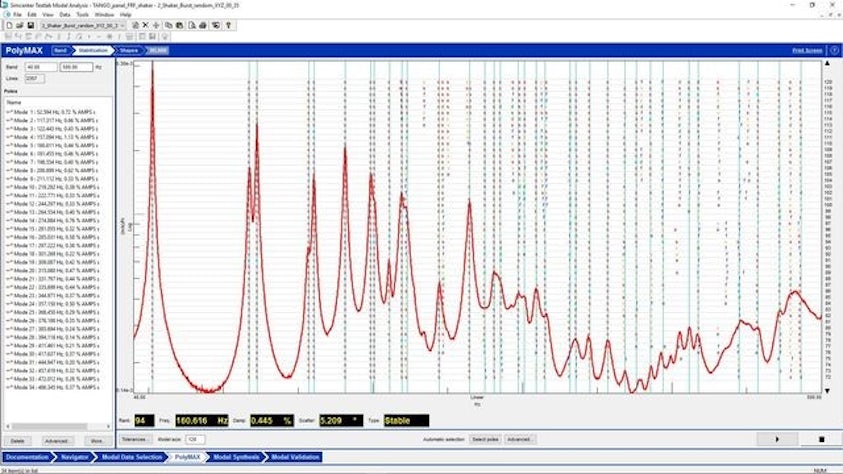

구조 동역학 테스트를 실행하려면 많은 시행착오가 따르고 설정에 오랜 시간이 걸리던 시대는 이제 끝났습니다. Simcenter 테스트 솔루션을 활용하면 모달 테스트 및 모달 해석을 수행하는 데 필요한 시간을 며칠에서 몇 시간으로 줄일 수 있습니다. Siemens의 통합 솔루션은 최신 모달 매개변수 식별 방법을 제공하여 문제의 근본 원인에 집중하고 구조적 약점을 최적의 방법으로 해결할 수 있도록 지원합니다.

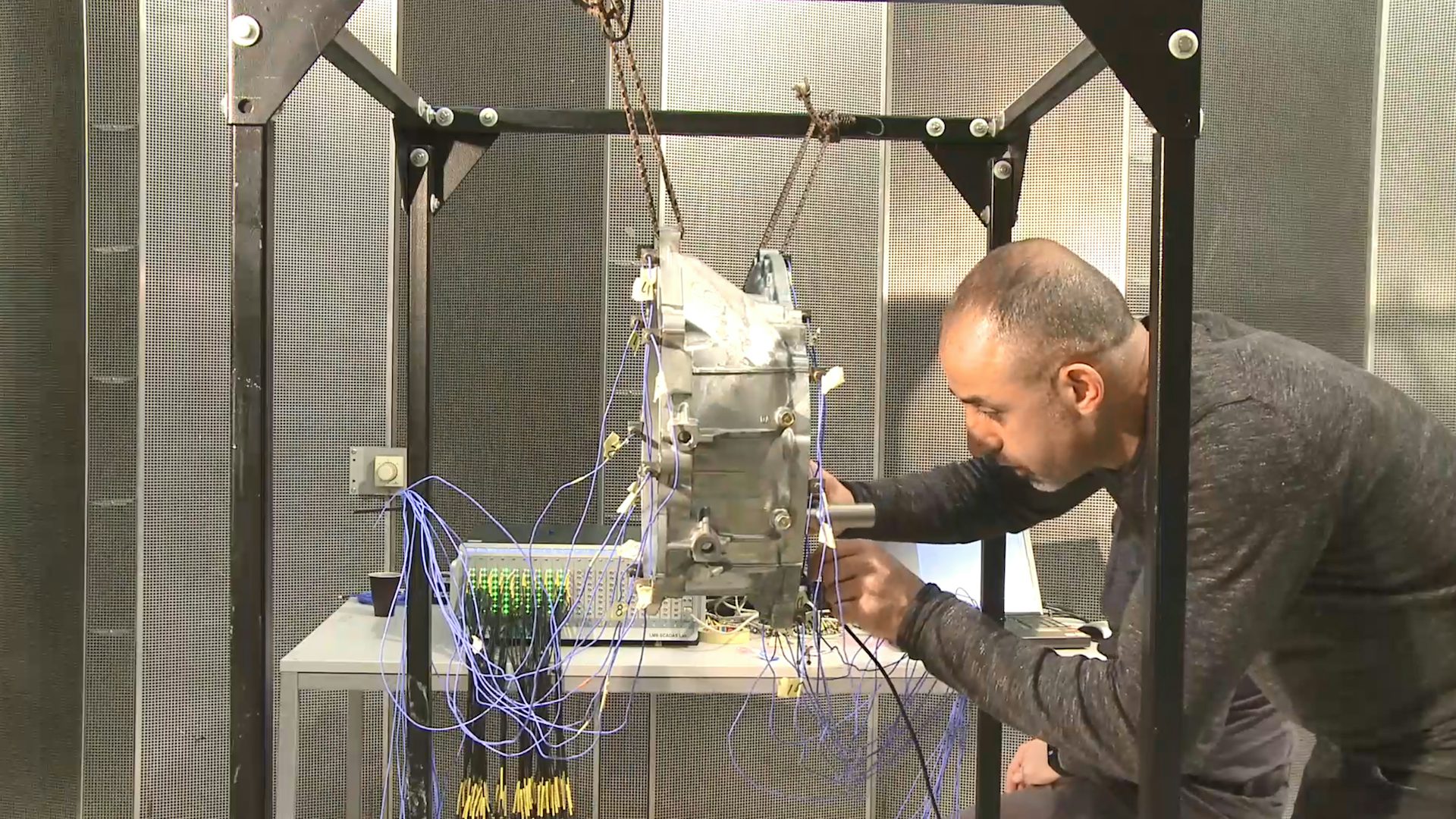

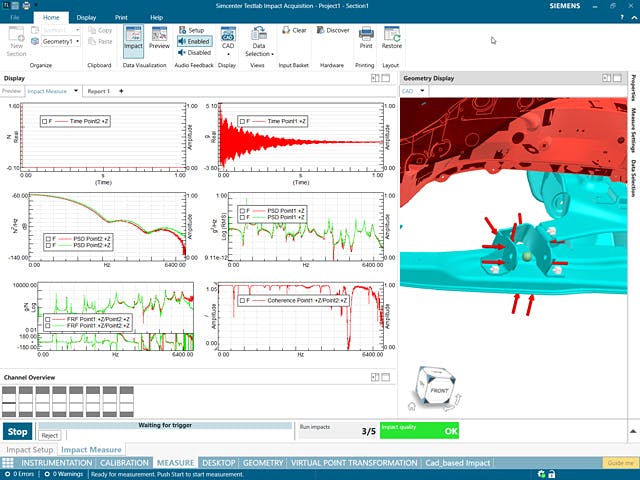

작은 구조에 대한 충격 테스트를 수행하거나 수 백 개의 측정 채널을 사용해 대규모 캠페인을 실행하는 경우, 또는 실험 데이터로 3D 유한 요소 모델을 검증하는 경우 40년 간의 모달 테스트 경험을 바탕으로 최첨단 엔지니어링 전문성을 활용하고 테스트 효율성을 극대화할 수 있습니다.

Siemens의 솔루션에는 디지털 이미지 상관관계(DIC)와 같은 고급 방법이 통합되어 있습니다. 이 기술을 사용하면 단 두 대의 고해상도 카메라로 부하에 관계없이 전체 필드 3D 데이터를 측정할 수 있으므로 정확도가 향상되고 검증 테스트 속도를 크게 높입니다.

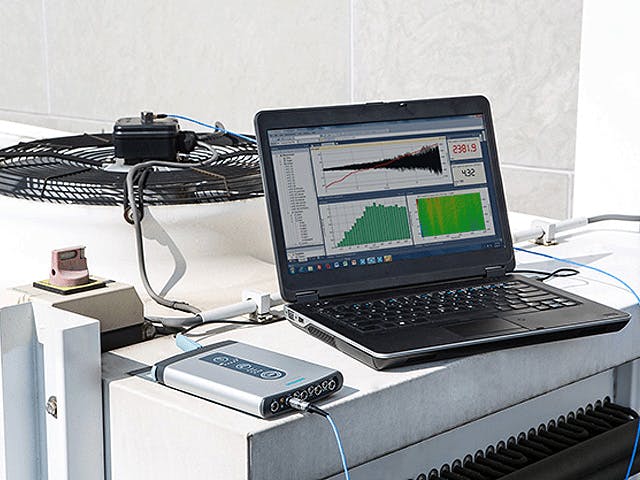

진동, 센서 및 계측의 기본

본 웨비나에서 모달 해석의 기본과 이를 활용해 소음 또는 진동 문제의 근본 원인을 파악하고 이를 효율적으로 해결하는 방법에 대해 알아보십시오.