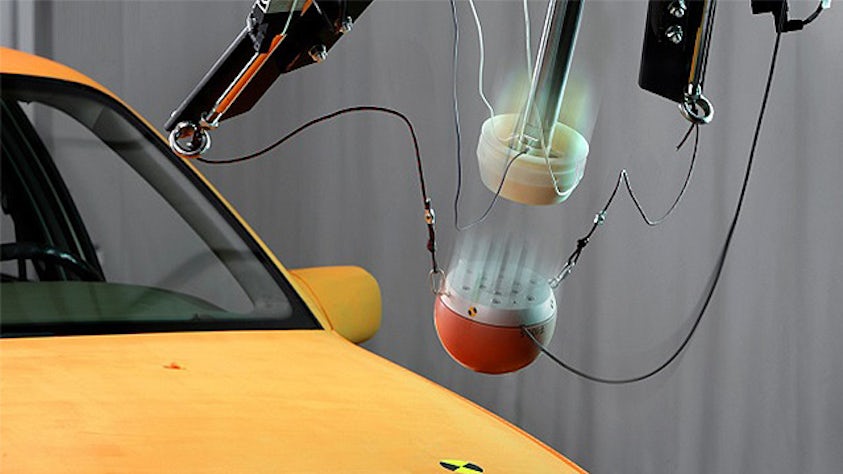

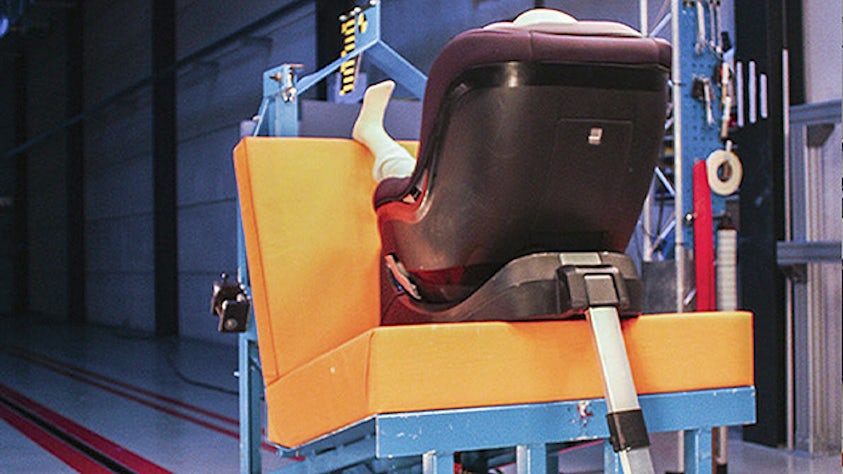

네덜란드 헬몬드의 안전 테스트 서비스는 EN ISO/IEC 17025 인증(등록 번호 L547)을 받았으며 RDW(E4) 및 KBA(E1)의 인증을 받았습니다. 테스트 센터는 헬멧에서 전체 구속 시스템에 이르기까지 광범위한 안전 구성 요소 및 시스템 테스트를 제공합니다. Siemens는 개발 시험과 함께 제품의 전 세계 표준 준수 여부에 대한 최종적이고 독립적인 검증을 제공합니다.

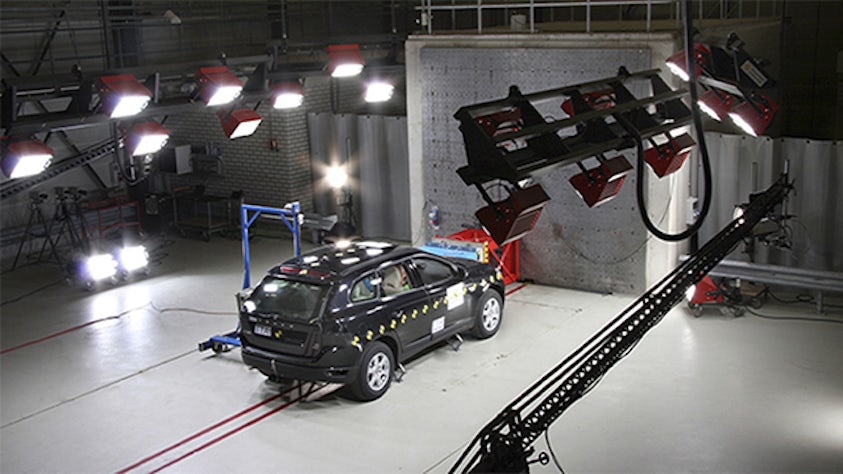

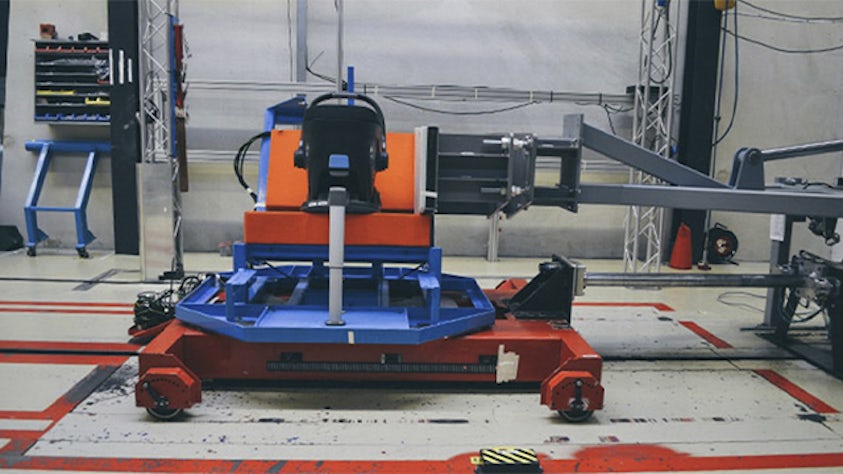

특정 안전 구성 요소 시험과 함께 전반적인 차량 안전도 시험합니다. 30년 이상의 경험을 바탕으로 Siemens는 다양한 수동적 및 능동적 안전 시스템을 개발, 엔지니어링, 시험 및 검증하기 위한 시뮬레이션 소프트웨어와 보충 지식 및 도구를 제공합니다. Siemens의 시험 시설은 실내외에서 다양한 자동차 용도의 시험을 수행할 수 있는 완벽한 장비를 갖추고 있습니다.