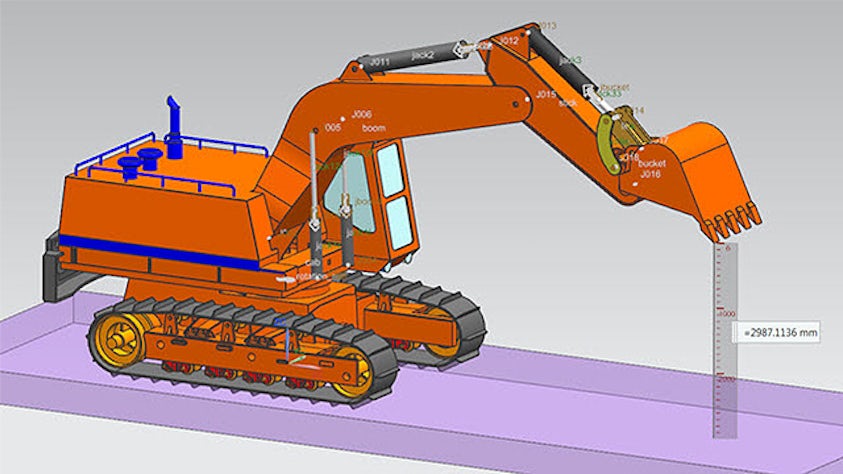

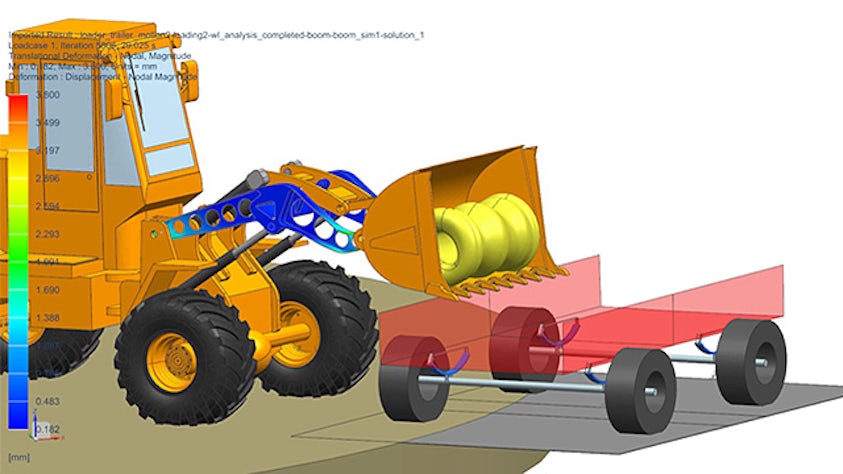

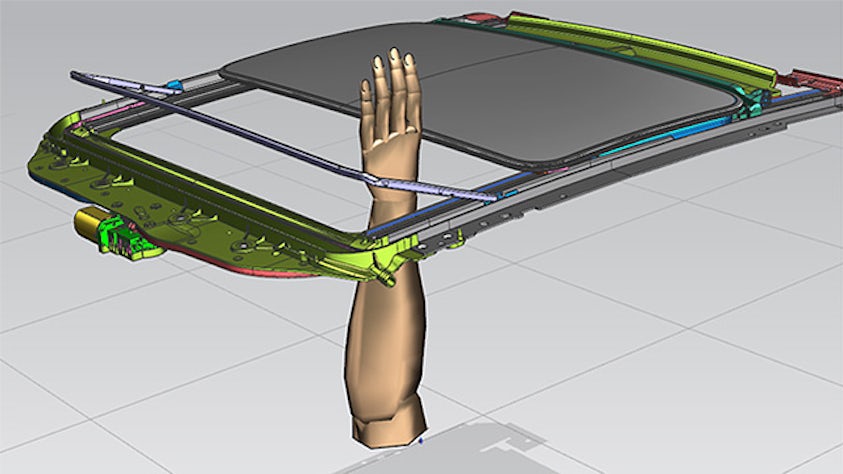

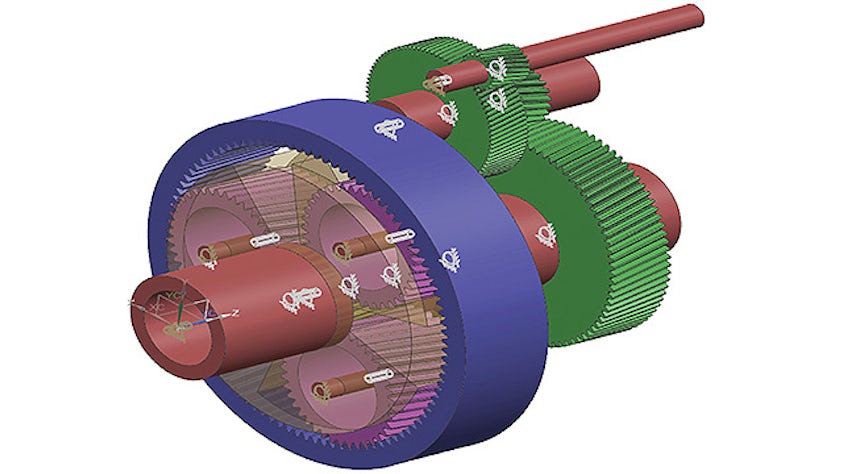

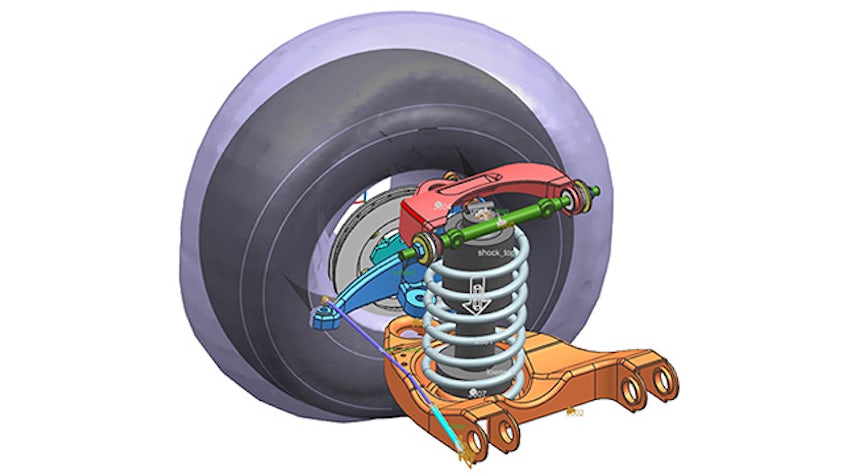

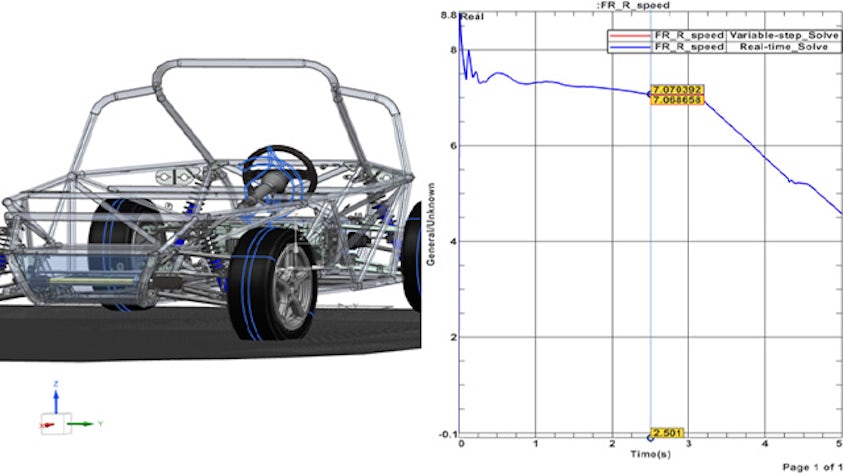

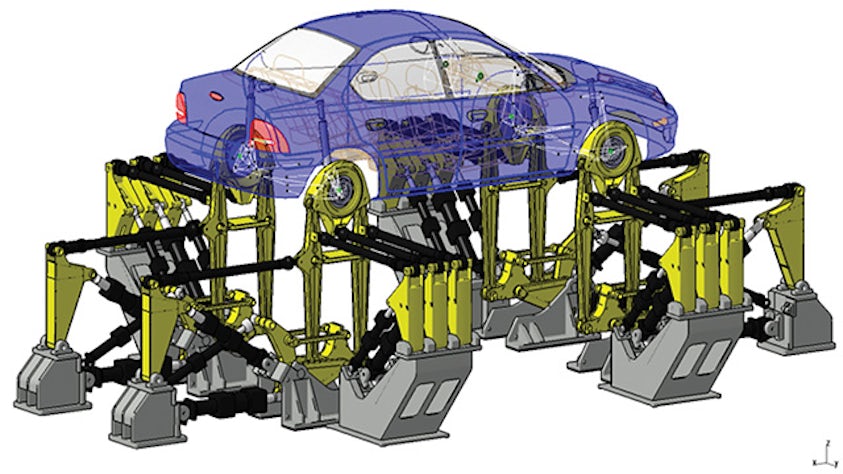

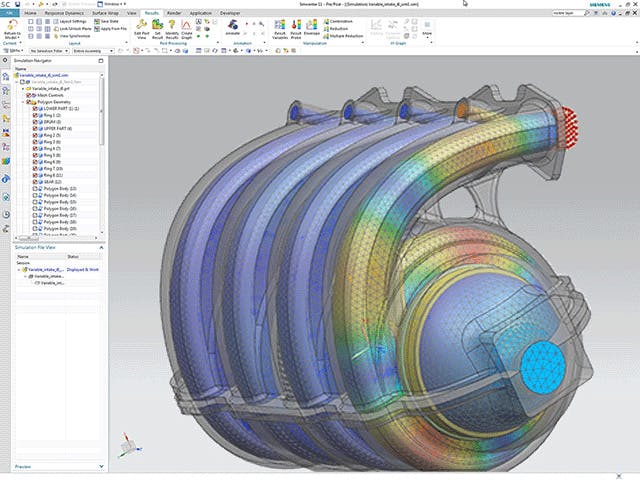

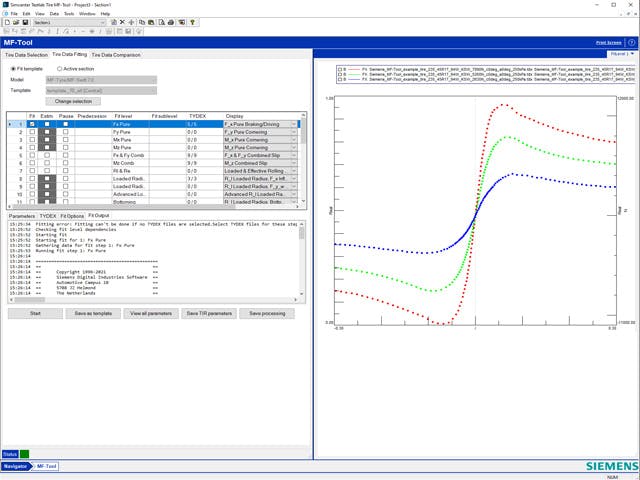

윙 플랩 또는 랜딩 기어, 슬라이딩 선루프 또는 서스펜션, 복사기 및 기타 메커니즘과 같은 복잡한 기계 시스템 엔지니어링 성능을 파악하기는 매우 어렵습니다. 모션 시뮬레이션은 기계 시스템의 반작용 힘, 토크, 속도, 가속도 등을 계산하기 위해 다물체 동역학을 사용합니다. CAD 지오메트리와 어셈블리 구속조건을 정확한 모션 모델로 바로 변환하거나, 원하는 다물체 모델을 처음부터 생성할 수 있습니다. 내장된 모션 솔버와 강력한 후처리 기능을 통해 광범위한 메커니즘 동작을 연구할 수 있습니다.

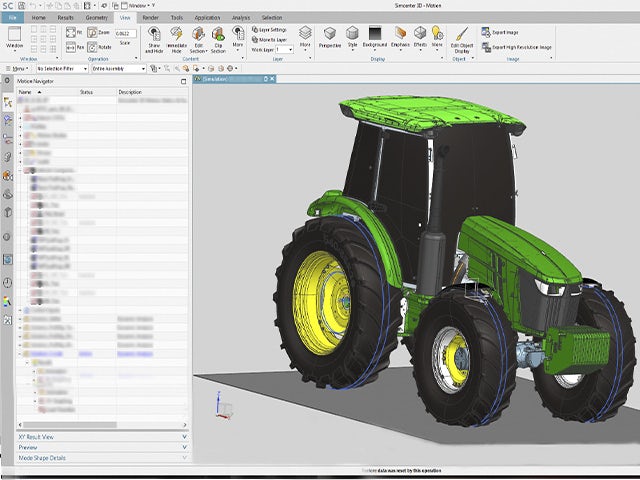

Simcenter 모션 시뮬레이션 소프트웨어를 사용하면 엔지니어는 메커니즘의 기능적 동작을 이해하고 예측할 수 있습니다. 고급 동적, 정적 및 키네마틱 모션 시뮬레이션의 모든 측면을 지원하는 완전한 기능 세트가 제공됩니다.

모션 시뮬레이션용 Simcenter 3D 솔루션 가이드

초반에 모션 시뮬레이션을 사용하는 것은 설계 신뢰도를 높이고 위험을 줄이는 데 핵심적입니다.