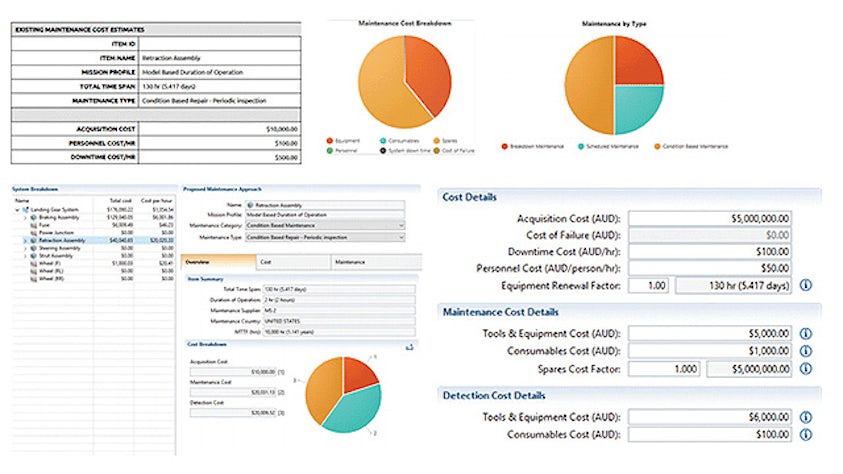

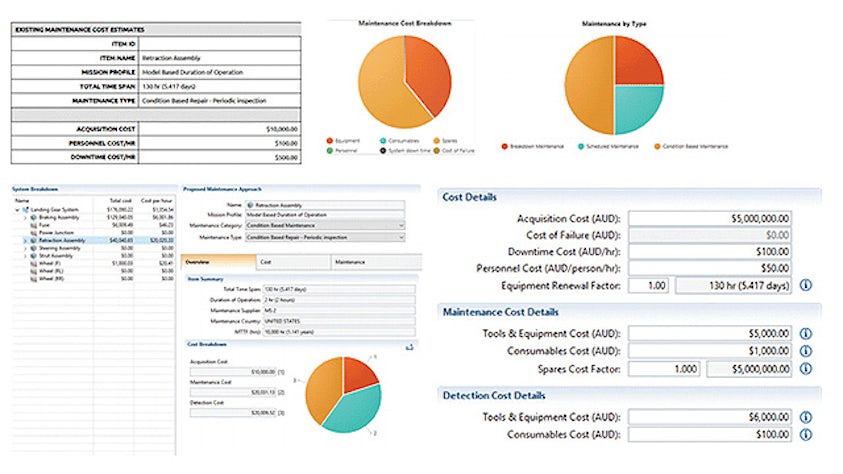

설계 구성, 관련 임무 프로필, 운영 환경 및 유지보수 접근 방식을 기반으로 유지보수 비용에 대한 분석 및 거래 연구를 실현합니다. 자산의 시스템, 하위 시스템 및 주요 어셈블리에 대한 정확한 비용을 추정한 다음 이를 사용하여 수명 기간 내내 들어가는 유지보수 관련 비용을 대체 유지보수 개념과 비교합니다.

엔지니어가 특정 설계 상태/운영 구성에 맞게 조정할 수 있는 시뮬레이션 분석을 기반으로 제품 라이프사이클의 각 단계에서 설계 및 서비스 권장 사항을 생성할 수 있습니다.

설계 구성, 관련 임무 프로필, 운영 환경 및 유지보수 접근 방식을 기반으로 유지보수 비용에 대한 분석 및 거래 연구를 실현합니다. 자산의 시스템, 하위 시스템 및 주요 어셈블리에 대한 정확한 비용을 추정한 다음 이를 사용하여 수명 기간 내내 들어가는 유지보수 관련 비용을 대체 유지보수 개념과 비교합니다.

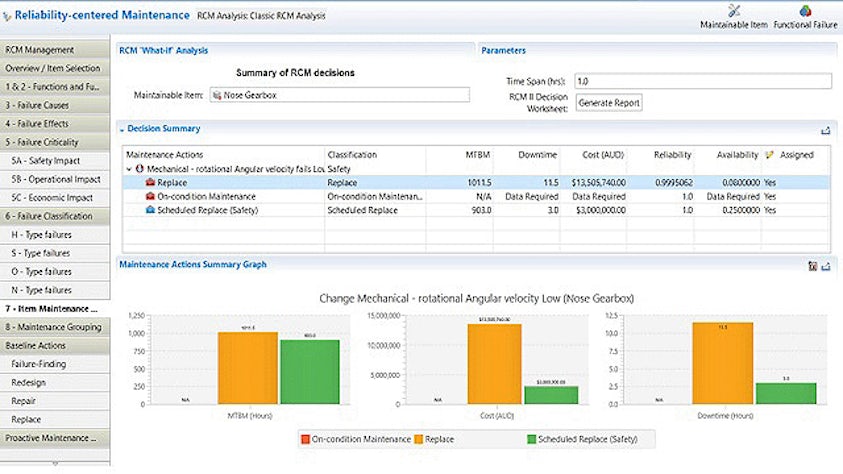

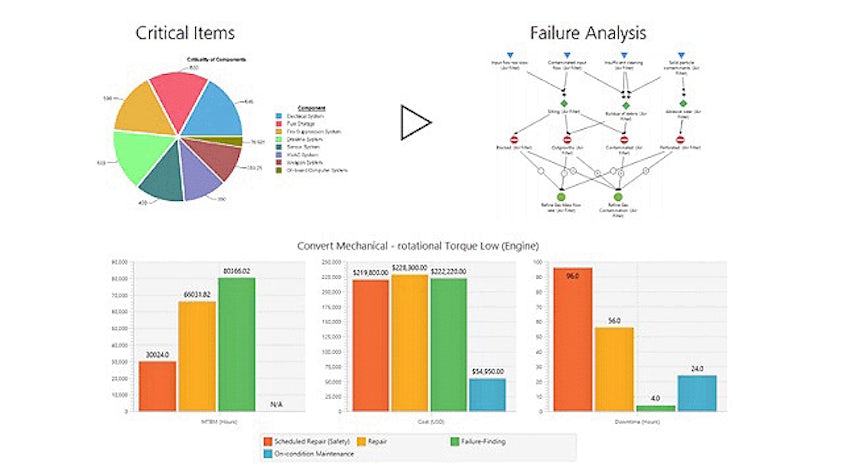

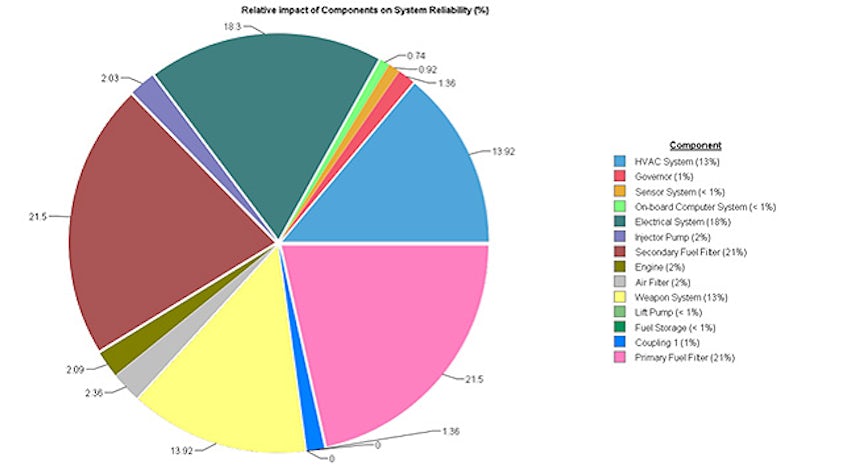

성능이 저하된 구성 요소를 파악하고, 신뢰할 수 없는 항목의 우선 순위를 지정하고 RCM(Back-Fit Reliability Centered Maintenance) 방법론으로 구성 관리 프로세스의 성능을 최적화하여 현재 유지보수를 최적화합니다. MER은 복잡한 플랫폼의 유지에 드는 잠재적인 비용, 일정 및 기술적 이점을 제공합니다.

시스템의 구성 요소 및 부품에 이르기까지 최고 수준의 신뢰성을 파악합니다. 시스템 엔지니어링 프로세스 중에 특정 목표를 요구사항으로 사용하면 엔지니어가 신뢰성 목표를 충족하는 항목을 자신 있게 설계하거나 획득할 수 있습니다. 항목이 나중에 더 광범위한 시스템에 통합될 때 신뢰성 목표에서 벗어나는 편차가 줄어들어 재설계의 위험과 비용이 감소합니다.

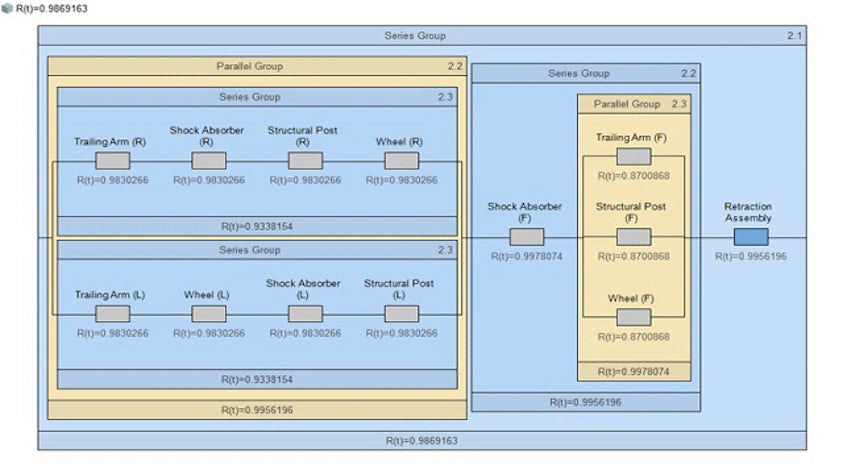

디지털 위험 트윈에서 직접 신뢰성 해석을 생성하므로 실시간 상황별 분석을 통해 설계 신뢰성을 추적할 수 있습니다. 직렬, 병렬, 대기 이중화, K/N 및 제외를 비롯해 광범위하고 복잡한 구성을 모델링합니다. 강력한 계산 엔진을 사용하여 신뢰성, 가용성, 유지보수성 및 라이프사이클 비용을 계산할 수 있습니다.

RCM 분석을 수행하여 예상 사용량 및 예상 신뢰성을 기반으로 최적의 유지보수 일정을 파악합니다. 조직의 엔지니어링 프로세스 내에 통합하도록 구성할 수 있는 대체 유지보수 접근 방식의 기술 타당성을 평가하고 비용을 비교합니다. 산업 표준(예: MSG3, MIL 3034, SAE-JA1012)을 준수하고 자산 라이프사이클의 단계마다 효율성과 비용 효율성을 유지합니다.