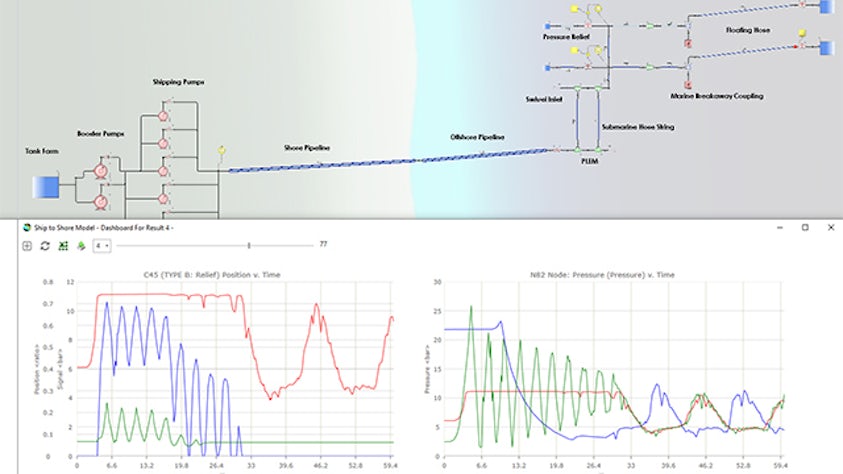

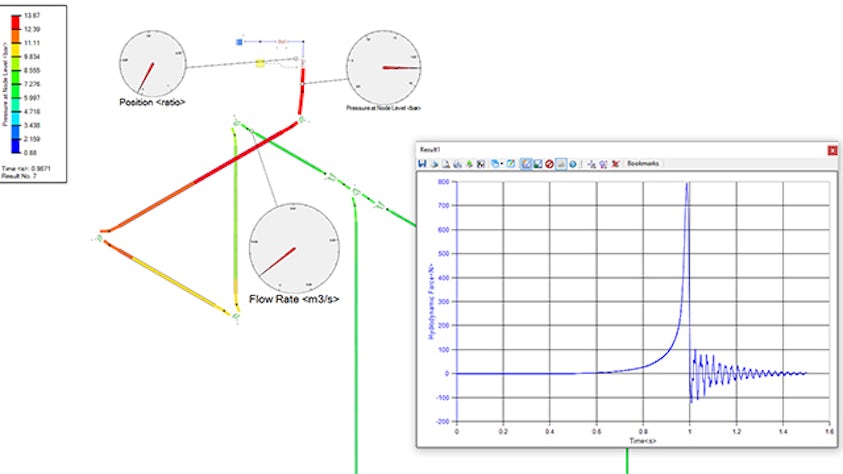

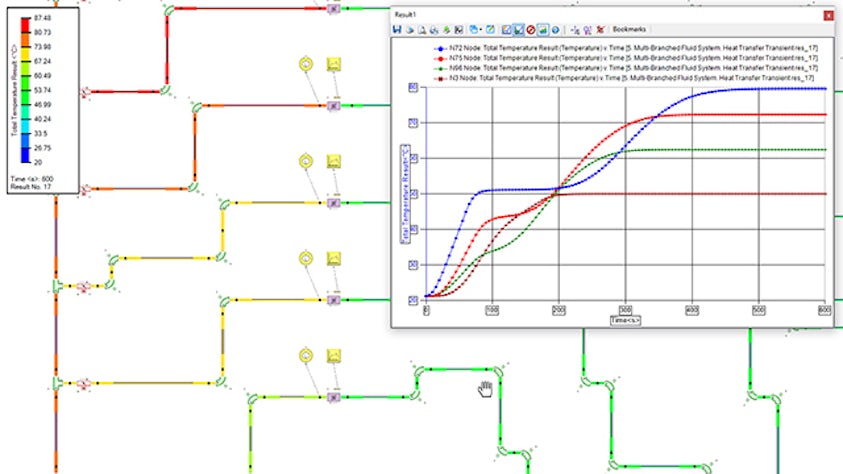

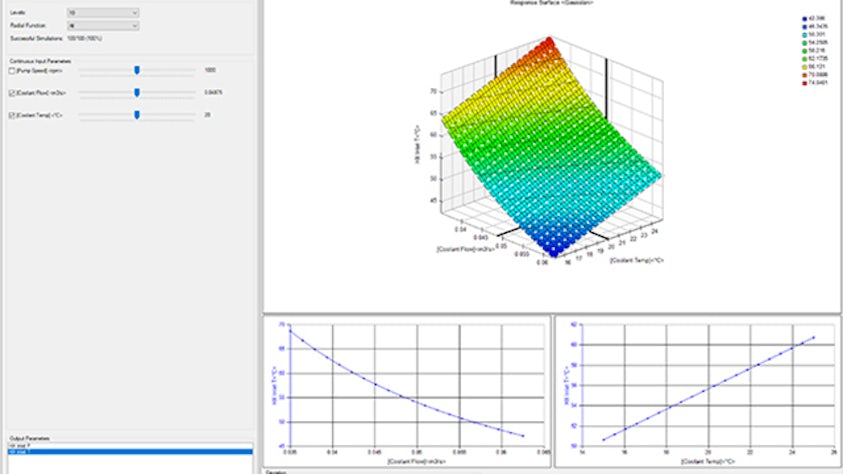

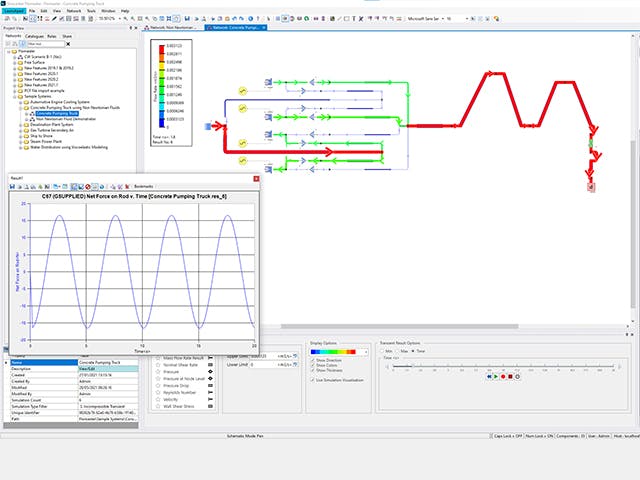

어떤 시나리오에서도 열 유체 시스템의 안전하고 효율적인 작동을 보장합니다. 빠르고 안정적이며 엄격한 테스트를 거친 천이 솔버를 통해 크기와 복잡성에 관계없이 열 유체 시스템의 동적 거동을 시뮬레이션할 수 있습니다. 초기 설계 중에 사용한 것과 동일한 모델을 천이 해석을 위한 상세 설계에서 시스템 및 컴포넌트 크기 조정을 위해 재사용합니다. 이를 통해 전체 엔지니어링 단계에서 모델 및 데이터의 연속성이 보장됩니다.

펌프 고장, 비상 밸브 폐쇄, 프라이밍, 블로우 다운 및 환기와 같은 중요한 시나리오에서 시스템의 동적 거동을 분석할 수 있습니다. 이 모델은 압력 서지, 라인 패킹, 플라스틱 파이프의 점탄성, 캐비테이션, 초킹 및 가스의 전체 압축성과 같은 복잡한 현상을 고려합니다.