Create sheet metal part designs

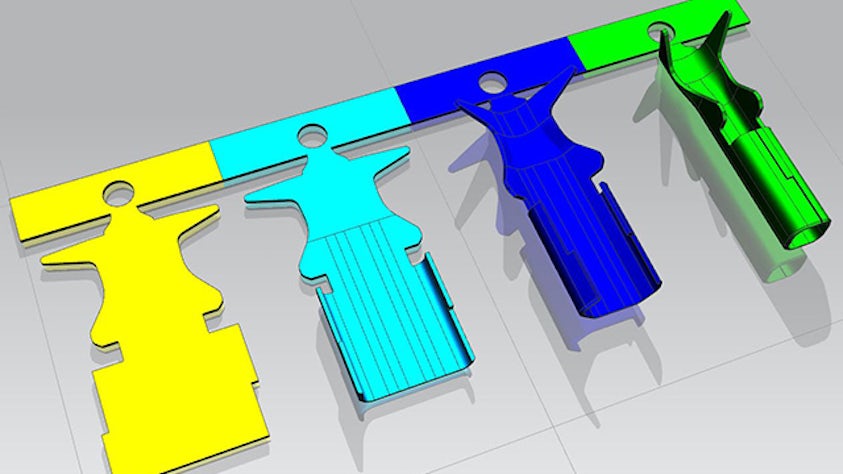

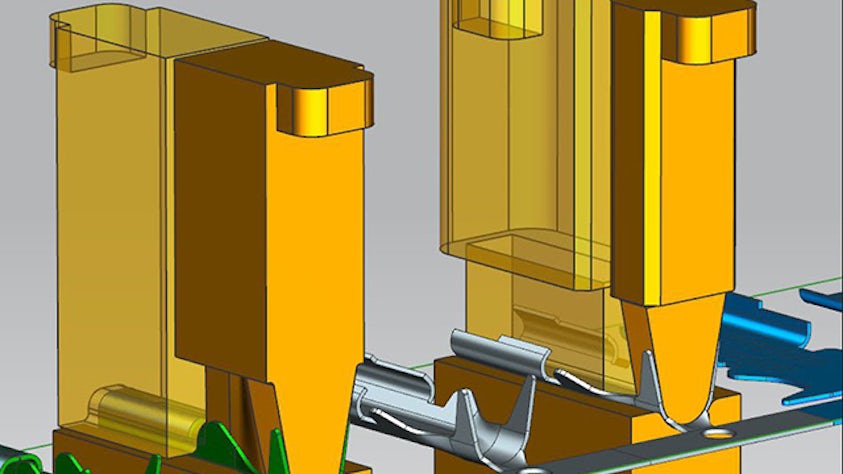

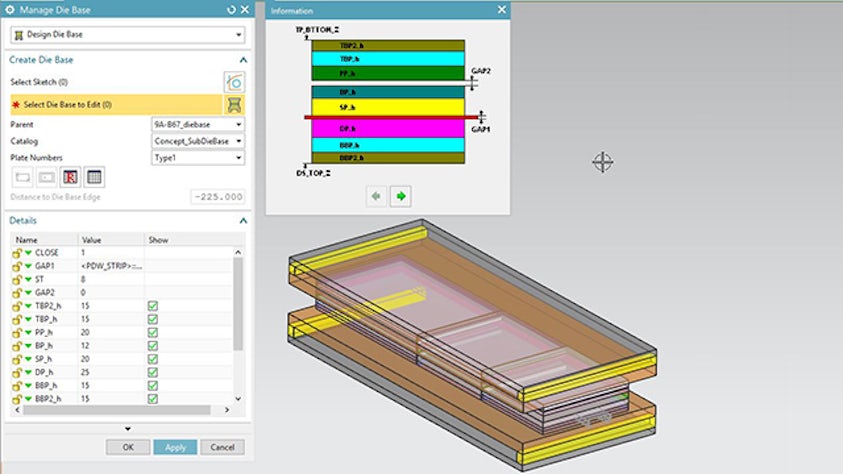

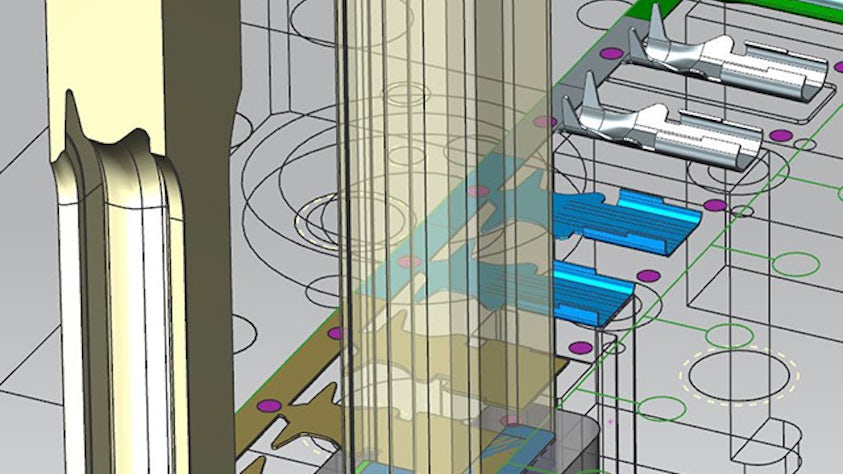

Optimize the design of both straight break and freeform sheet metal parts with a broad set of sheet metal functions. Leverage feature recognition, bend table and direct unfolding capabilities to design associative intermediate stage parts with prebends and overbends.

Apply One-step Unforming and Formability Analysis technology to create intermediate forms and flattened blank shapes for complex freeform parts.