부품 배치 및 네스팅

부품 위치에 대한 완벽한 제어와 빌드 볼륨 내에서 자동화된 효율적인 네스팅을 통해 부품을 효율적으로 프린트할 수 있습니다. 이것이 NX가 빌드 트레이를 효율적으로 채우기 위한 통합 도구를 제공하는 이유입니다. 부품을 수동으로 배치하든 통합 2D 및 3D 네스팅을 통해 자동으로 배치하든 NX는 효율성과 품질 목표 달성을 위한 완벽한 제어 기능을 제공합니다.

적층 제조(AM) 프로세스의 핵심은 준비입니다. Siemens의 빌드 준비 솔루션은 NX CAD/CAM 환경에 통합되어 파일 변환이나 비용이 많이 드는 빌드 설정 재작업 없이 부품 설계의 변경이 제조 설정까지 원활하게 반영되도록 지원합니다.

부품 위치에 대한 완벽한 제어와 빌드 볼륨 내에서 자동화된 효율적인 네스팅을 통해 부품을 효율적으로 프린트할 수 있습니다. 이것이 NX가 빌드 트레이를 효율적으로 채우기 위한 통합 도구를 제공하는 이유입니다. 부품을 수동으로 배치하든 통합 2D 및 3D 네스팅을 통해 자동으로 배치하든 NX는 효율성과 품질 목표 달성을 위한 완벽한 제어 기능을 제공합니다.

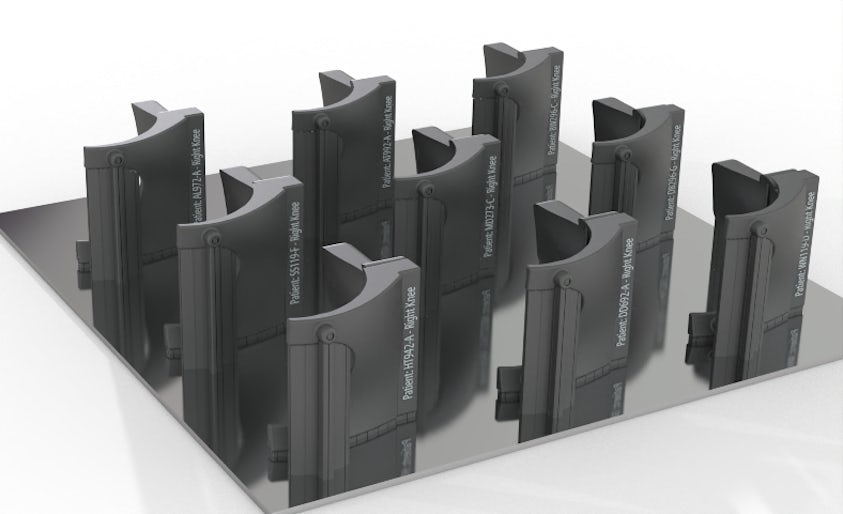

AM 생산의 추적과 인증을 위한 인쇄 마크 생성을 완벽하게 제어할 수 있습니다. 많은 빌드에서 빌드 트레이의 부품은 고유한 표시나 번호로 일련 번호를 지정해야 합니다. 이는 NX AM 빌드 준비 시스템 내에서 수행할 수 있으며, 여기서 고유 식별자는 수동, 프로그래밍 방식 또는 스프레드시트 인터페이스를 통해 적용할 수 있습니다.

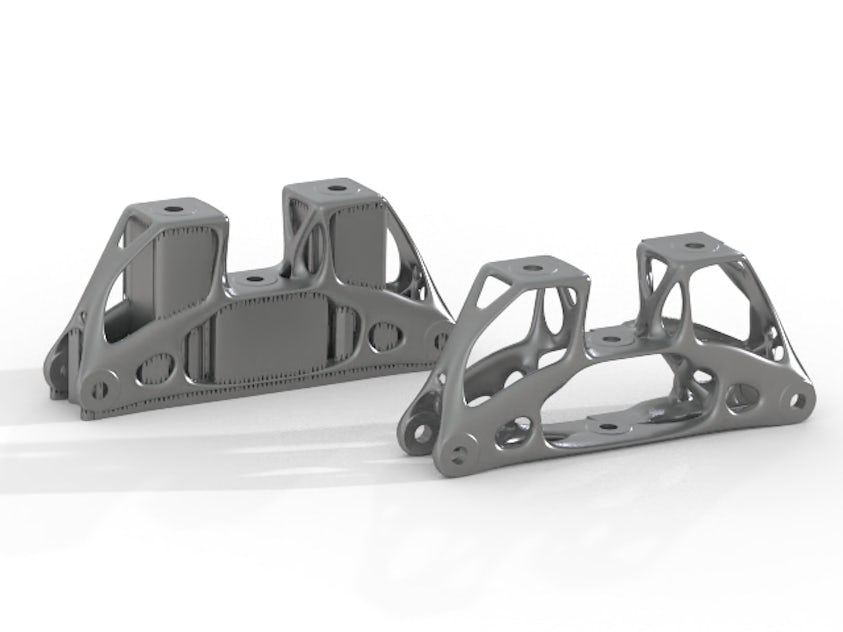

고품질의 지지 구조물을 생성하고 빌드할 수 있습니다. 많은 적층 제조 기술에서 고품질 빌드는 고품질의 지지 구조물에 달려 있습니다. NX는 지지 구조물의 자동 생성을 위한 솔루션은 물론, 사용자 지정 지지대 설계를 위한 전체 NX CAD 솔루션에 대한 액세스를 제공합니다. AM 초보자부터 전문 사용자까지 이 긴밀한 통합을 통해 최종 제품 품질이 가장 중요한 부품을 프린트할 때 큰 이점을 얻을 수 있습니다.

회사:Unlimited Tomorrow

업종:의료 및 제약

위치:New York City, New York, United States

Siemens Software:NX

실용적인 산업용 적층 제조 설계를 위한 당사의 전문 솔루션을 확인하십시오.