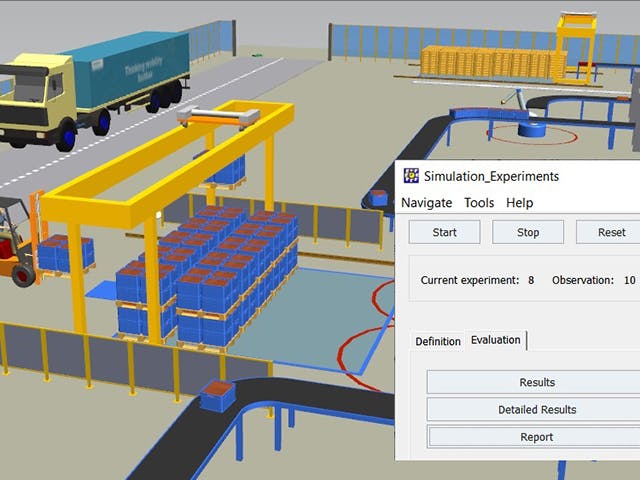

객체 지향 3D 시뮬레이션 환경에서 모델링

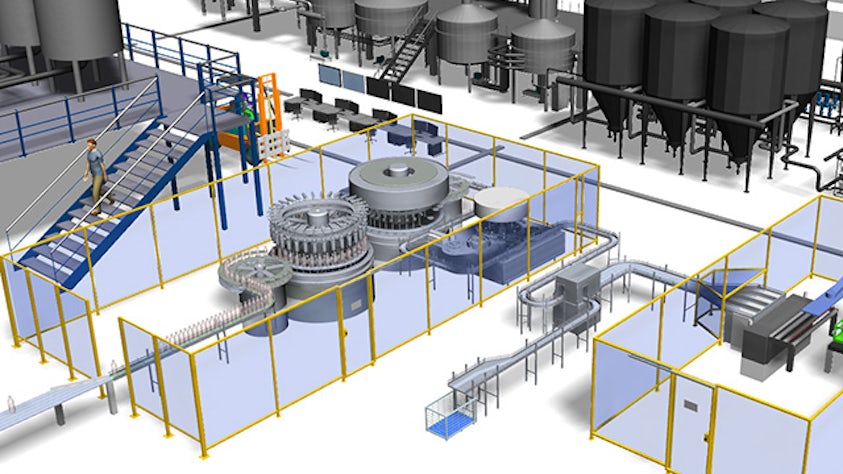

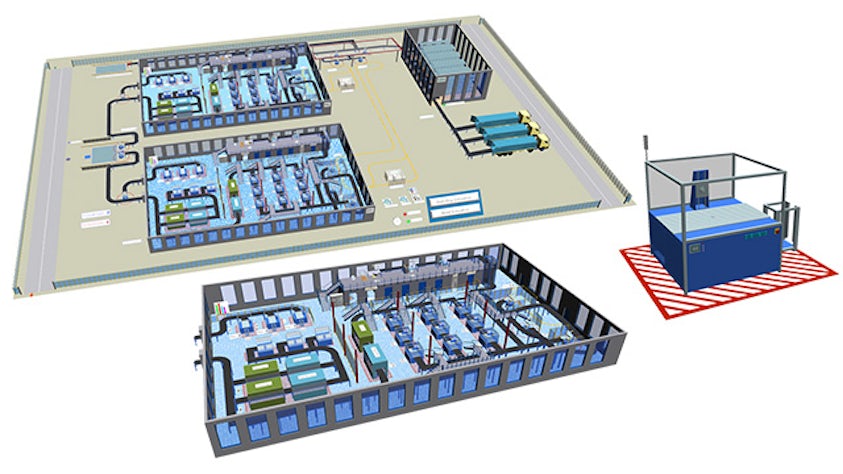

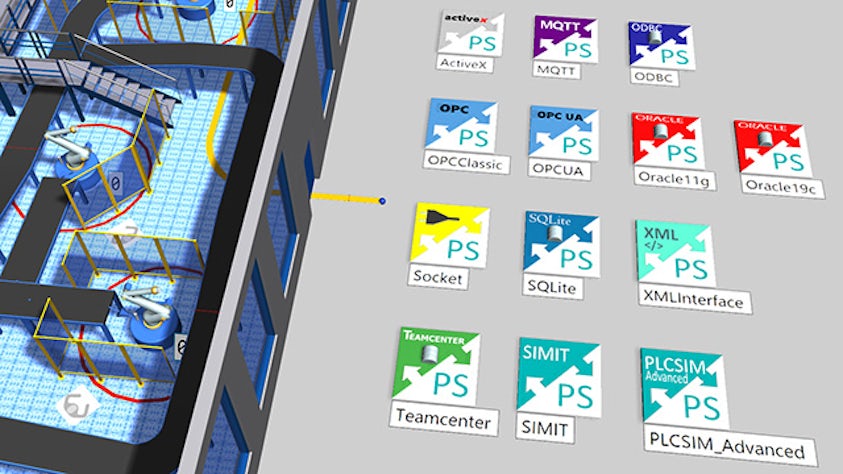

강력한 객체 지향 아키텍처 및 모델링 기능을 사용해서 생산 설비, 라인 및 운영에 대한 체계화된 3D 계층 모델을 생성하여 이산 제조 또는 연속 제조 프로세스를 빠르고 효율적으로 모델링합니다.

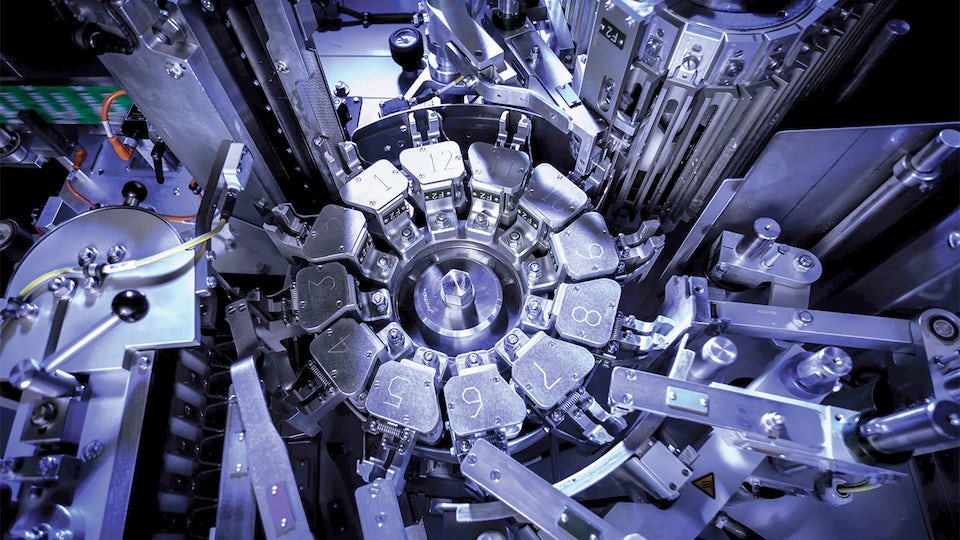

포함된 라이브러리 또는 외부 CAD 데이터를 사용하여 3D로 빌드하고 시각화합니다. 3D 모델링을 위한 JT 데이터 형식과 Siemens 다이렉트 모델 기술을 활용하여 시뮬레이션 및 분석 요구사항을 절충하지 않으면서 대규모 3D 시뮬레이션 모델을 효율적으로 로드하고 사실적으로 시각화합니다.