제조 지오메트리를 자동으로 식별

코어와 캐비티의 제조 프로세스를 자동화하여 정의할 수 있습니다.

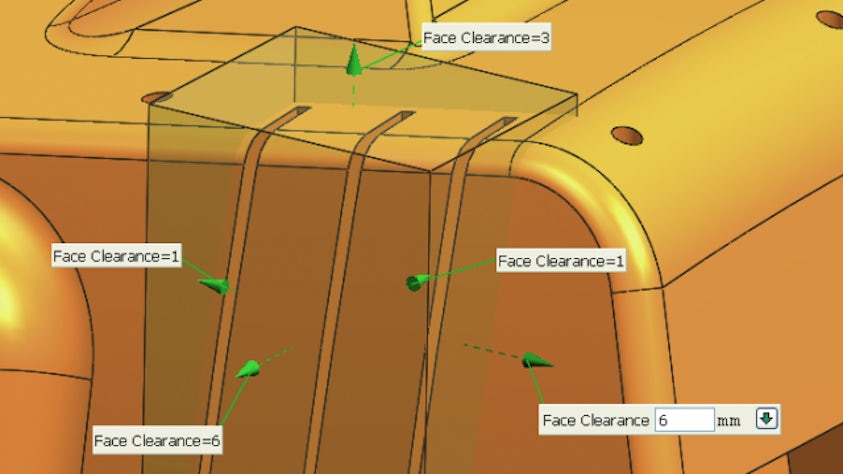

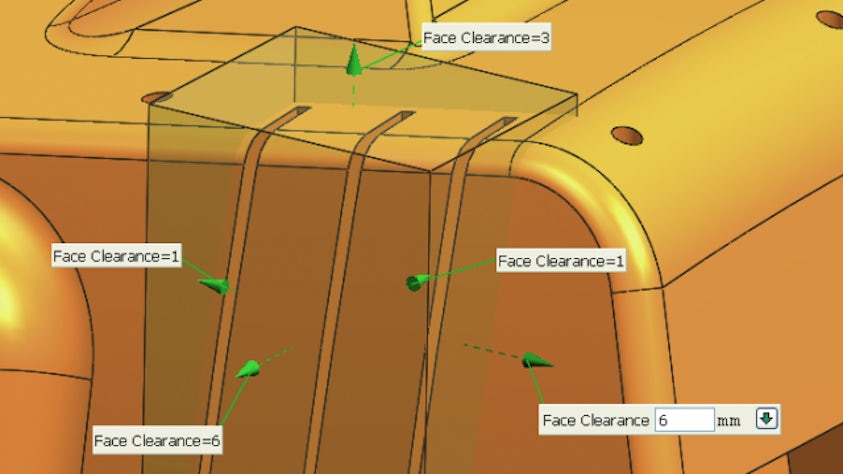

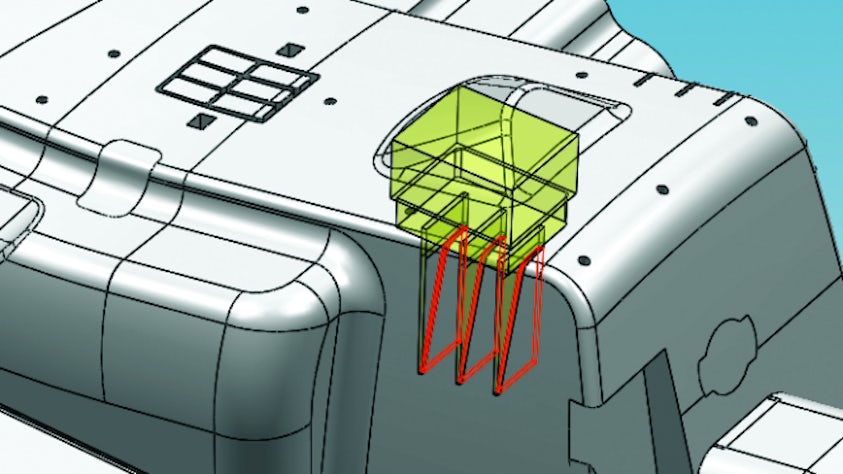

EDM, 와이어 EDM(WEDM), 밀링 및 연삭을 통해 버닝하고 황삭하려는 면을 자동으로 검색, 인식, 그룹화 및 컬러 코딩할 수 있습니다.

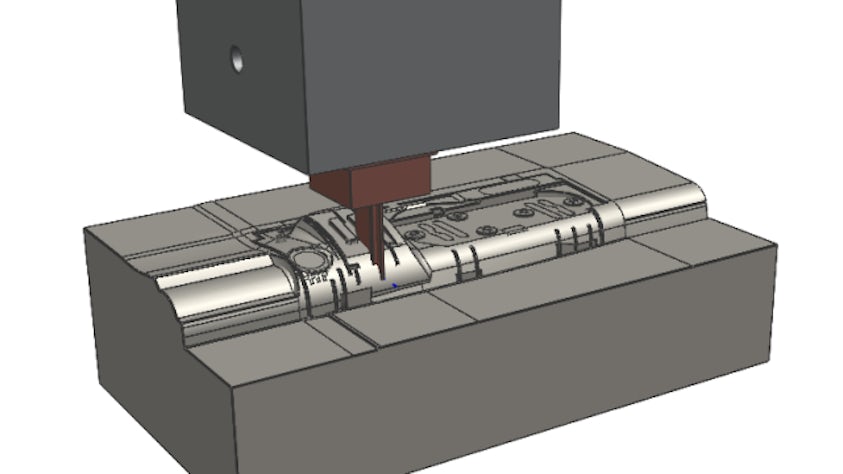

설계에서 생산까지 전체 EDM(전극 방전 가공) 프로세스를 자동화하여 가장 복잡하고 까다로운 전극도 효율적으로 모델링

코어와 캐비티의 제조 프로세스를 자동화하여 정의할 수 있습니다.

EDM, 와이어 EDM(WEDM), 밀링 및 연삭을 통해 버닝하고 황삭하려는 면을 자동으로 검색, 인식, 그룹화 및 컬러 코딩할 수 있습니다.

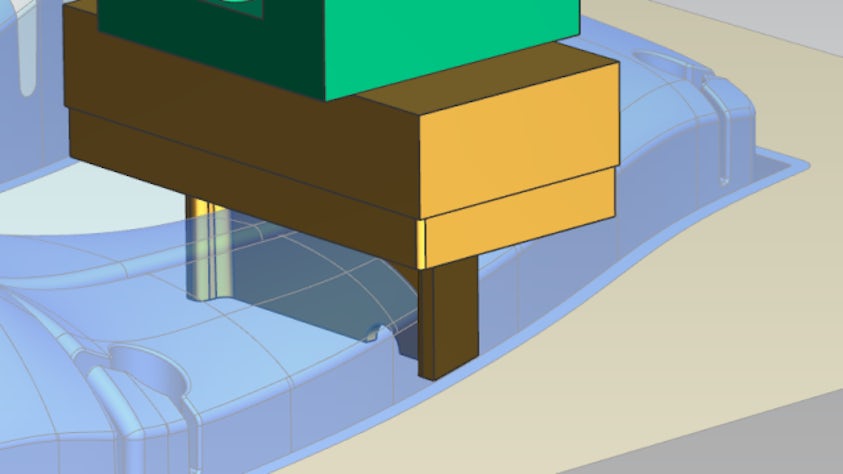

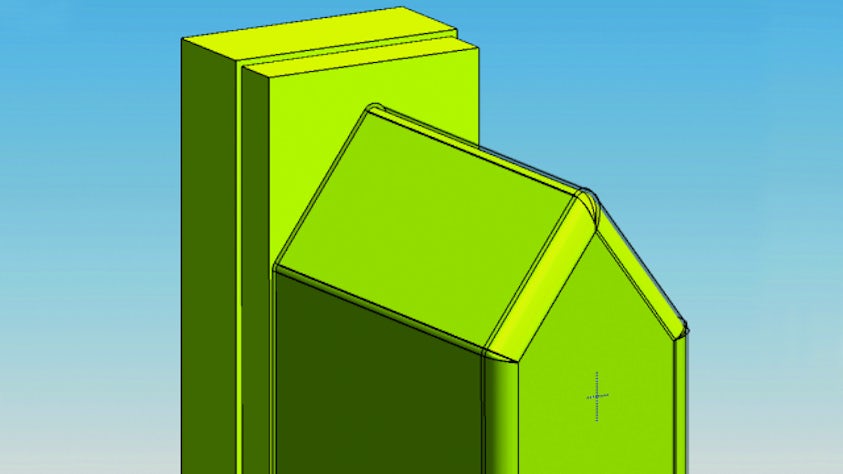

전문적이고 강력한 기능으로 전극 헤드/버닝 영역의 형상을 모델링합니다.

연관성이 있는 매우 복잡한 형상을 설계합니다. 코어와 캐비티에 대한 설계 변경 사항이 전극, 도면, 가공에 원활하게 전파되도록 보장합니다.

NX의 고급 도구를 사용하여 실제보다 작은 전극 지오메트리를 빠르게 설계할 수 있습니다.

스파크 갭과 궤적 모션을 보정할 수 있습니다. 즉시 사용 가능한 궤적 유형에는 원형, 정사각형 및 구형이 포함됩니다. 사용자 정의 궤적도 쉽게 만들 수 있습니다.

제조 곡면의 설계 버전을 교체하고 관련 전극, 전극 도면, 공구 경로를 자동으로 업데이트할 수 있습니다.

적절한 EDM 기계 설정을 결정할 때 간섭을 확인하고 스파크 영역을 계산하여 다운스트림 제조 작업을 최적화할 수 있습니다.

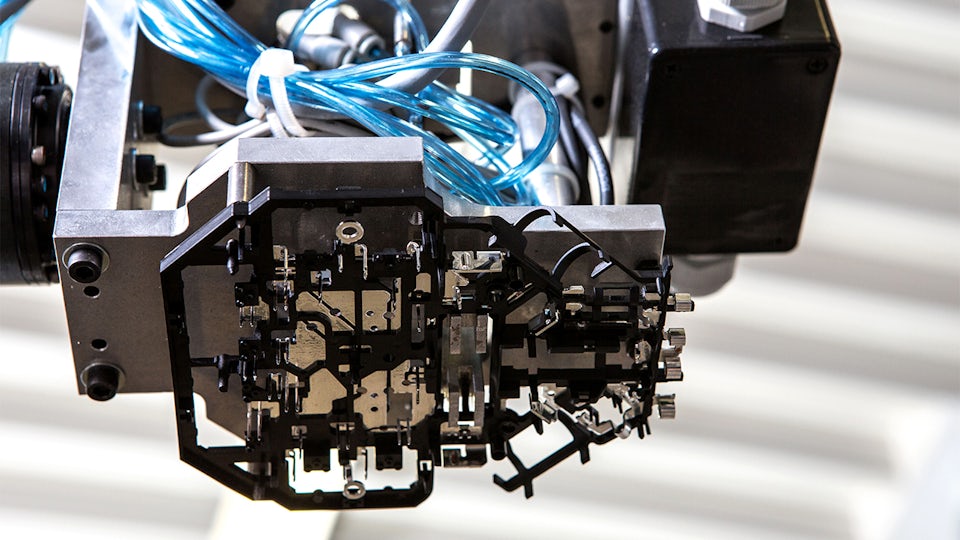

회사:Pollmann

업종:자동차 및 운송

위치:Karlstein, Austria

Siemens Software:NX, Teamcenter, Tecnomatix