가공 정밀도 매개변수를 제품 설계 및 제조 계획 프로세스의 일부로 통합하여 비용이 많이 드는 제품 품질 문제를 방지합니다.

- 설계 릴리스 전에 치수 변동의 영향을 파악하여 생산 단계에서 제품 품질을 보장

- 제조 프로세스가 설계 특징형상 및 공차에 미치는 영향을 분석하고, 치수 변동의 원인과 크기를 강조 표시하여 제조 품질을 개선하고 비용을 절감

가공 정밀도 매개변수를 제품 설계 및 제조 계획 프로세스의 일부로 통합하여 비용이 많이 드는 제품 품질 문제를 방지합니다.

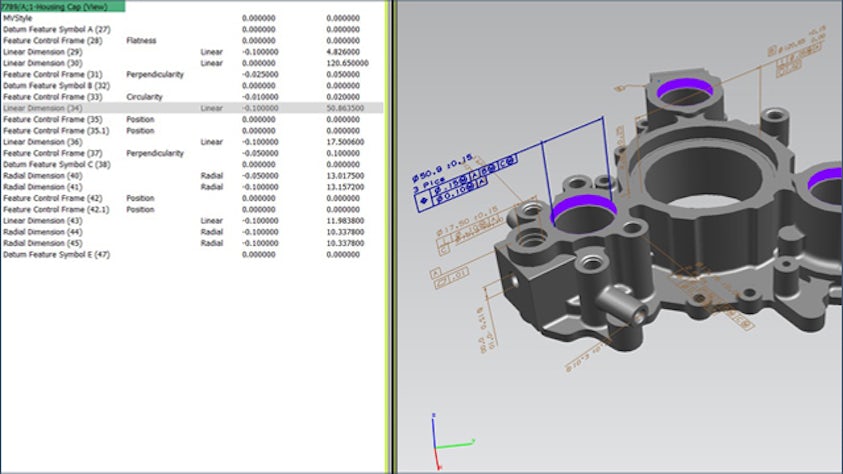

모델 기반 품질 엔지니어링을 지원하기 위해 PMI(제품 제조 정보)의 시맨틱 표현을 활용하여 특징형상 및 공차 정의를 자동화하고 가공 정밀도를 향상합니다.

업계 표준의 JT™ 데이터 형식을 통해 다양한 작성 소스에서 PMI를 추출하고 검증합니다. 이를 통해 GD&T(지오메트리 치수 지정 및 공차) 방법 및 표준을 기반으로 하는 공차와 모든 가공 정밀도 분석 및 검사 요구사항에 필요한 다운스트림 계산, 증가 및 소비를 사용하는 형상 기반의 기능을 제공합니다.

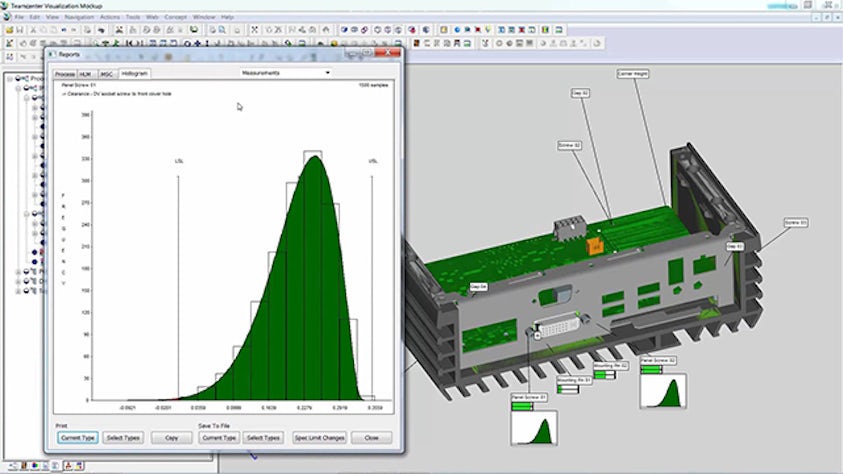

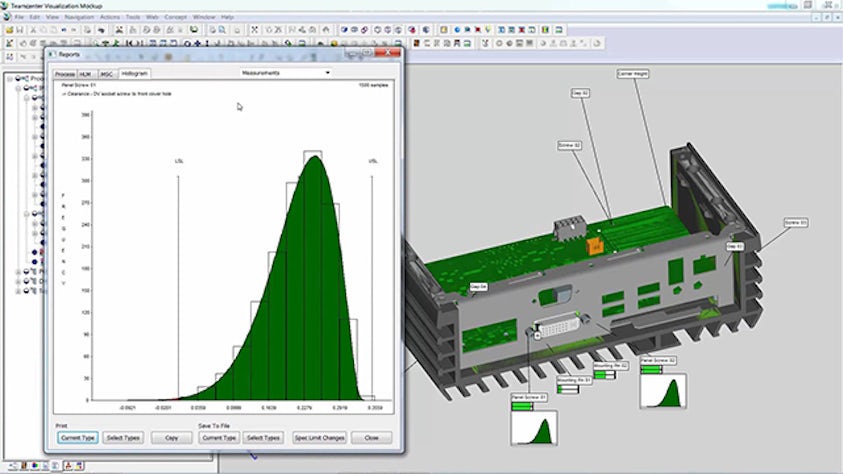

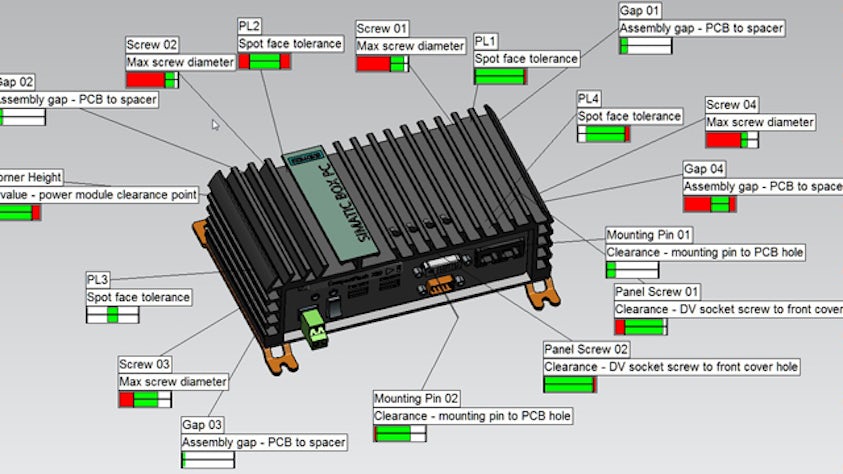

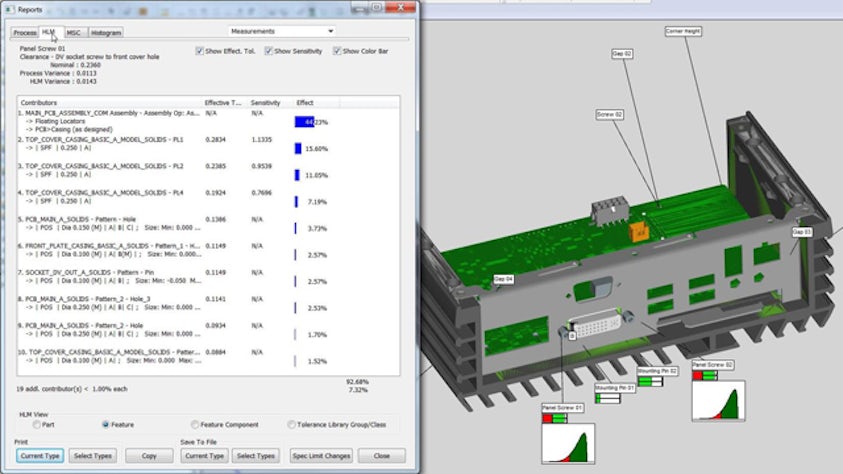

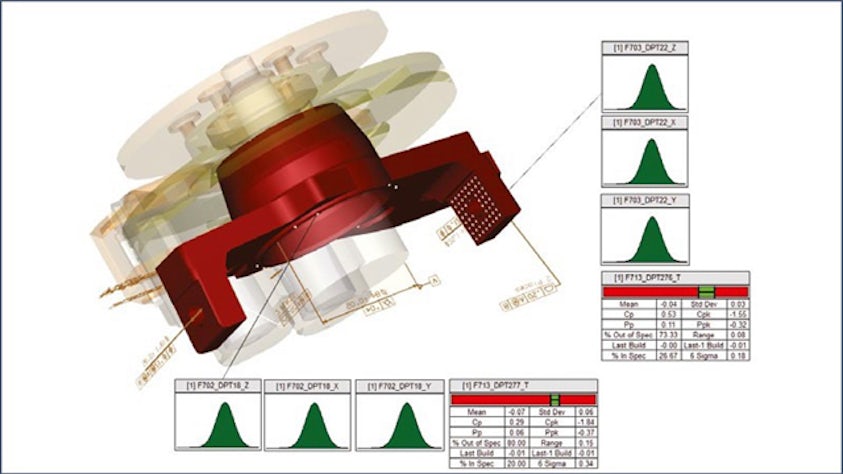

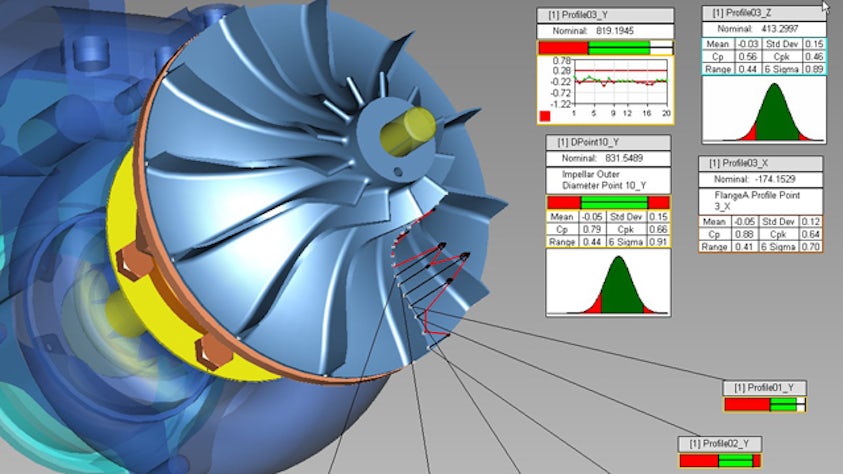

치수 분석을 통해 제조 및 어셈블리 프로세스를 시뮬레이션하여 강력한 3D 환경에서 변동의 크기와 출처를 예측하고 정량화할 수 있습니다.

이 소프트웨어는 Monte Carlo 시뮬레이션과 결합 어셈블리 구속조건 엔진을 활용하여 허용 가능한 모든 구속조건 범위 내에서 정적 어셈블리 및 키네마틱 어셈블리 작업을 수행합니다. 유한 요소 해석 솔버와 통합하여 클램핑, 용접 및 스프링백으로 인한 컴포넌트 유연성을 파악할 수 있습니다.

허용 가능한 파트 공차를 최대화하는 동시에 중요한 어셈블리 치수 사양을 제어하여 제조 비용을 절감할 수 있습니다. 이러한 치수 특성을 제어하여 스크랩, 재작업 및 보증 결함을 최소화할 수 있습니다. 변동의 핵심 요인인 주요 치수, 공차 및 어셈블리 프로세스를 식별할 수 있습니다.

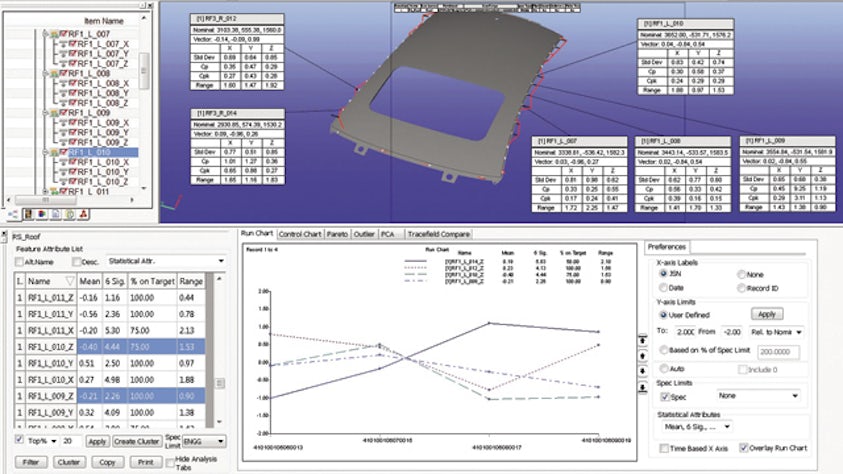

변동 해석에 제조 기능 데이터를 추가하면 생산 빌드 문제에 대한 근본 원인 분석을 실시간으로 수행할 수 있으므로 파트가 처음부터 제대로 맞도록 하여 품질을 개선할 수 있습니다.

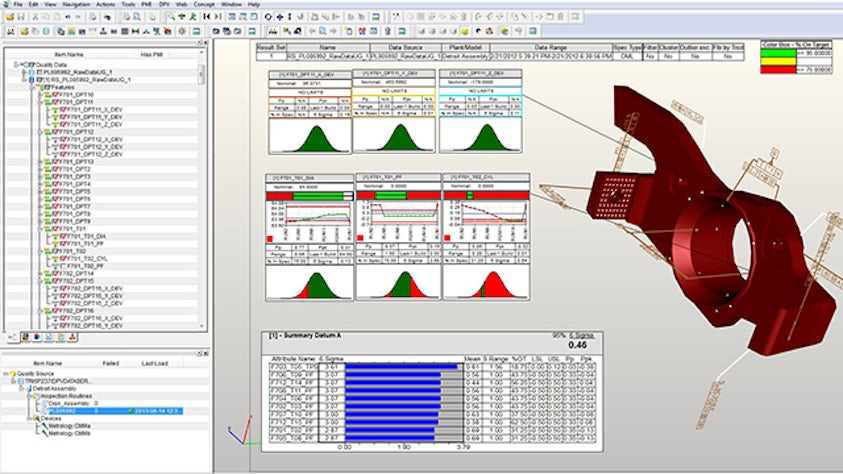

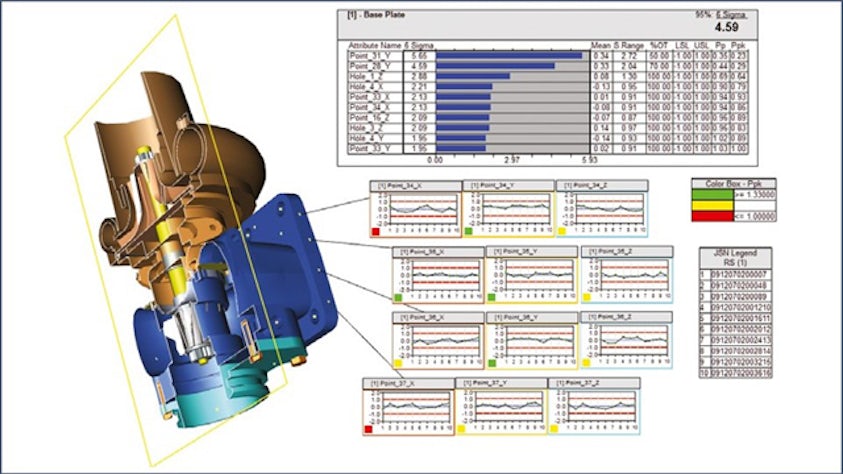

측정된 제품 품질 데이터의 실시간 수집, 저장, 관리, 보고 및 분석을 통해 빌드 품질을 확보하고 보장하여 오류를 더 빠르게 수정합니다.

보고서 게시를 자동화하여 수집된 품질 측정값을 사전 구성된 보고서 템플릿을 쉽게 채울 수 있습니다. 방대한 양의 측정 데이터를 통합하는 기록 요약 보고서를 생성하여 의사 결정자가 이 정보를 신속하게 검토하고 이를 사용하여 측정값에 기반한 설계 및 제조 의사 결정을 내릴 수 있습니다.

프로세스 또는 공장을 비교하고, 프로세스 안정성을 파악하고, 특정 기간의 회사의 제조 성과를 요약할 수 있습니다.

제조 데이터베이스에서 설계된 측정 지점과 측정 계획을 관리, 업데이트 및 캡처하는 프로세스를 계획합니다. 의사 결정자는 언제 어디서나 이 데이터에 액세스하여 원하는 정보를 검색할 수 있습니다.

제품 설계, 제조 계획 및 공장 레이아웃과 함께 연계된 측정 프로세스를 정의하여 생산 시작 및 실행 전에 치수 측정이 빌드 품질 계획 프로세스에 통합되도록 합니다.

생산 중에 모든 장치에서 측정 데이터를 모니터링 및 캡처하고 자동화된 도구로 Teamcenter 소프트웨어로 로드하여 품질 추세를 사전에 파악할 수 있습니다.

모든 형식 및 후처리 요구사항에 대한 지원을 활용할 수 있습니다. 공장의 모든 측정 장치에서 수집한 품질 데이터를 단일 시스템으로 통합하여 빌드 품질을 더 효과적으로 파악할 수 있습니다.

정교한 통계 기법과 3D 지오메트리 기능을 결합하여 생산에서 발견되는 품질 문제의 근본 원인을 신속하게 파악할 수 있습니다.

설계와 생산 간의 격차를 해소하여 파편화된 품질 솔루션의 한계를 극복합니다. 빌드 품질 지식을 주요 제품 설계 및 제조 프로세스에 직접 연결하고 통합합니다.

Chery Automobile은 Teamcenter 및 Tecnomatix 소프트웨어를 사용하여 연구 개발의 효율성과 품질을 높입니다.

회사:Chery Automobile

업종:자동차 및 운송

위치:Wuhu, Anhui Province, China

Siemens Software:NX, Teamcenter, Tecnomatix