산업화 적층 제조를 위한 솔루션

Siemens의 강력한 소프트웨어 포트폴리오를 통해 설계에서 생산에 이르는 전체 적층 제조 프로세스를 실행할 수 있습니다. 아래 내용을 읽어보고 적층 제조를 산업화하는 데 필요한 것이 무엇인지 알아보십시오.

DfAM(Design for Additive Manufacturing)

고품질 적층 제조 프로세스의 시작은 항상 설계에 있습니다. AM은 최적화된 표면 및 격자 구조와 같은 기능을 갖춘 매우 복잡한 설계를 제조할 수 있는 기능을 제공합니다. 당사의 적층 제조 솔루션을 사용하면 복잡한 지오메트리를 대규모로 설계하고 프린트할 수 있습니다.

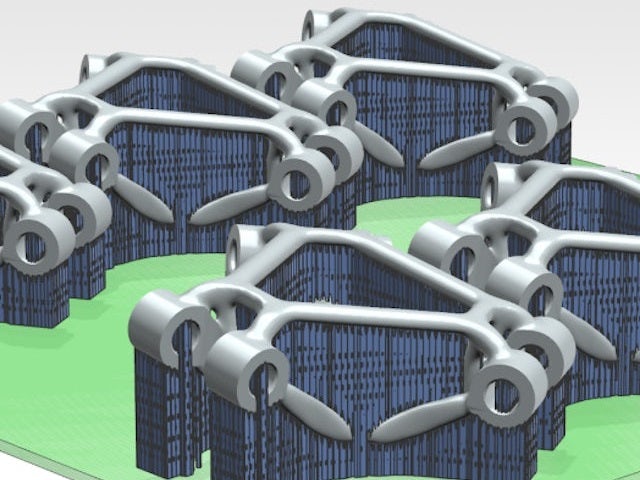

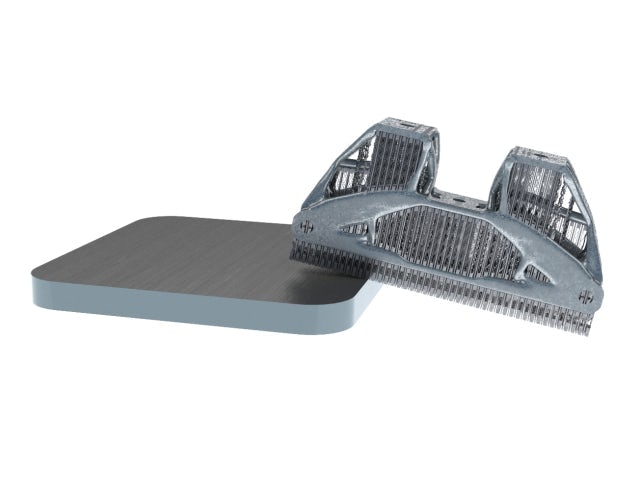

프린트 빌드 준비

AM 프로세스에서 고품질의 효율적인 출력을 위해서는 적절한 설정이 필요합니다. NX의 통합된 빌드 준비 도구는 가장 효율적인 방식으로 빌드 트레이에 부품을 배치, 방향 지정, 지지할 수 있도록 지원합니다.

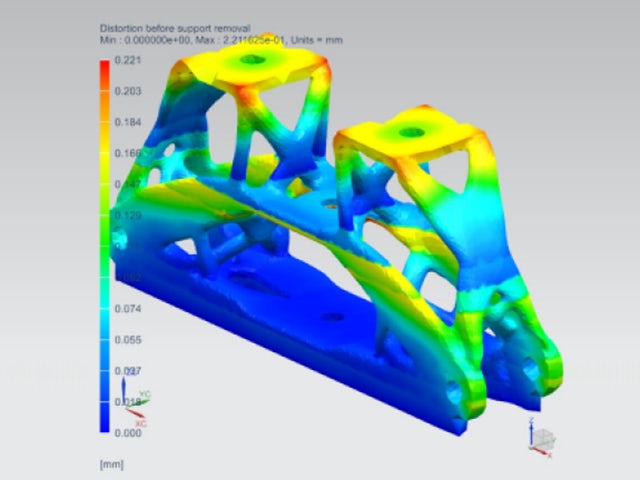

빌드 시뮬레이션

빌드 프로세스의 시뮬레이션을 통해 고품질 3D 프린트를 대규모로 생성할 수 있습니다. 빌드 방향 최적화에서 중간 규모 증착 경로 최적화에 이르기까지, NX는 한 번에 성공적으로 프린트할 수 있는 도구를 제공합니다.

기계 연결성

Siemens NX를 통해 다양한 3D 프린팅 하드웨어에 연결할 수 있습니다. 일부 시스템에는 평면 파우더 베드 시스템, 필라멘트 증착 시스템, 다중 재료 시스템 및 다축 시스템이 포함됩니다.

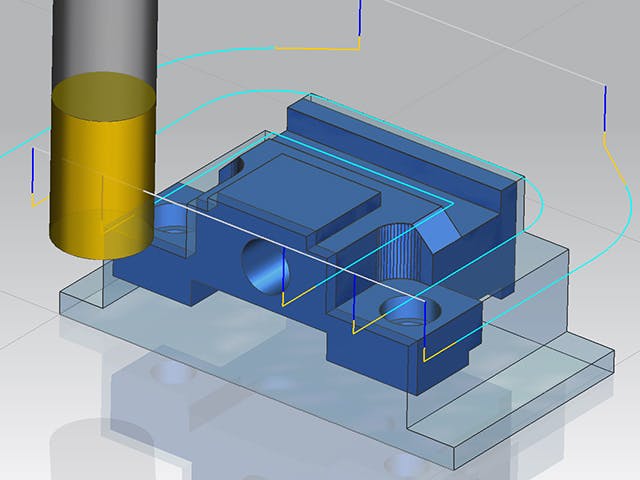

포스트 프린트 프로세싱

산업화된 3D 프린팅에는 강력한 포스트 프로세싱 소프트웨어가 필요합니다. 프린팅은 적층 제조 프로세스의 마지막 단계가 아닙니다. 분말 제거, 빌드 트레이에서 부품 제거 및 포스트 프로세스 가공은 전체 AM 프로세스의 모든 측면이며 모두 적층 제조 솔루션 세트의 일부입니다.

프로세스 관리

적층 제조 생산의 효율성을 극대화하려면 프로세스를 잘 관리해야 합니다. 여기에는 주문부터 배송까지의 프로세스뿐만 아니라 재료 관리 및 기계 스케줄링도 포함됩니다. 당사는 모든 규모의 기업을 위한 솔루션을 제공하여 전체 AM 프로세스의 효율성을 극대화함으로써 적층 제조 투자의 ROI를 극대화할 수 있도록 지원합니다.

LimaCorporate

NX를 사용한 3D 프린팅 임플란트 설계

회사:LimaCorporate

위치:이탈리아 산 다니엘레 델 프리울리, 빌라노바

Siemens Software:NX

크기:Medium

관련 AM용 NX 제품 살펴보기

실용적인 산업용 적층 제조 설계를 위한 당사의 전문 솔루션을 확인하십시오.