비즈니스 개선을 위한 커넥티드 제조

Teamcenter 제조 프로세스 계획 및 데이터 관리를 통해 생산 시간을 단축할 수 있습니다. 즉각적이고 안전하게 협업하여 부품 생산 및 어셈블리 작업을 최적화합니다. 조직과 플랜트를 아우르는 디지털 스레드를 통해 모든 관련 활동을 보다 효율적으로 실행할 수 있습니다.

클라우드의 제조 프로세스 관리

SaaS 제조 프로세스 관리는 클라우드에서 사용할 수 있으며 Siemens 전문가가 관리합니다. 모범 사례가 사전 구성되어 있어 바로 시작할 수 있습니다. 안전한 데이터 교환 및 프로세스 가시성을 통해 제조 정보의 연속성을 확보하십시오. 엔지니어링 및 제조 엔지니어, 기획자, 제조 현장 사용자, 파트너 및 공급업체, 라인 빌더, 설계 사무소 등을 연결해 줍니다.

손쉬운 제조 프로세스 계획 및 관리

MBOM(Manufacturing Bill of Materials) 및 BOP(Bill of Process) 데이터를 생성 및 관리하면 무엇을 어떻게 만들어야 하는지 파악할 수 있습니다. Siemens의 디지털 제조 솔루션과 통합된 Teamcenter는 엔지니어링, 제조 및 실행 간의 협업을 용이하게 합니다. 플랜트 전반에서 어셈블리 프로세스를 재사용하고, 작업 지침을 작성해서 제조 현장에 공유하며, 시간 분석 및 라인 밸런싱 등을 수행할 수 있습니다.

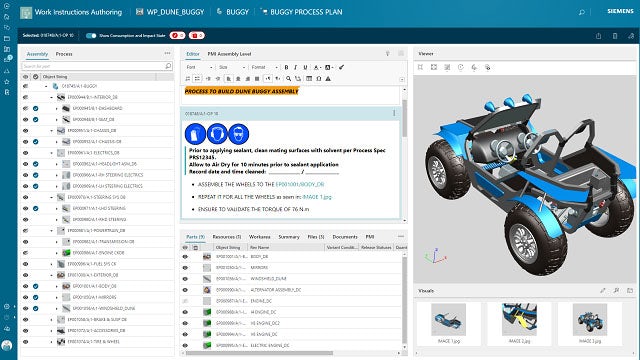

전자 작업 지침의 작성 및 공유

포괄적인 제조 작업 지침을 작성하여 제조 현장의 프로세스 단계를 더욱 명확히 할 수 있습니다. 최신 정보를 제공하고 2D 및 3D 시각화 도구와 AR 기술을 사용하여 BOM 단계를 명확하게 보여줍니다. 프로세스 문서가 리비전 관리를 통해 자동으로 업데이트되므로, 생산을 시작하기 전과 생산이 진행되는 동안에도 쉽고 빠르게 변경에 대응할 수 있습니다.

BOP(Bill of Process)의 작성 및 유지 관리

BOP 내에서 어셈블리 계획의 단계 순서에 대한 프로세스 및 작업을 작성합니다. MBOM에서 관련 부품 및 어셈블리를 작업에 할당하고, BOE(Bill of Equipment) 또는 분류된 객체 라이브러리를 통해 필요한 도구와 리소스를 지정합니다. 책임 검토 도구를 사용하여 제품 엔지니어링에서 BOP로의 변경이 간소화되므로 엔지니어링과 제조를 동기화할 수 있습니다.

엔지니어링 및 제조 BOM의 손쉬운 조정

Teamcenter의 통합 제품 및 프로세스 개발 플랫폼을 사용하면 설계 변경에 따라 어셈블리 프로세스 계획을 신속하게 업데이트할 수 있습니다. BOM 책임 검토 도구는 제품 및 제조 엔지니어가 제품 및 프로세스 변경의 영향을 신속하게 시각화하고 검증하는 데 도움이 됩니다. 이렇게 하면 후반 단계에 생산 문제를 파악해 비용이 많이 드는 상황을 방지할 수 있습니다.

작업 시간 추정 및 라인 밸런싱 수행

시간 관리 및 밸런싱 솔루션은 부가가치 및 비부가가치 제조 프로세스 활동에 대한 가시성을 제공합니다. 시간 분석에는 TiCon에 내장된 통합과 함께 MTM과 같은 시간 표준이 사용됩니다. 라인 밸런싱은 작업, 스테이션 및 작업자에 대한 시각적 시간 롤업을 표시합니다. 목표 Takt 시간에 맞게 계획을 최적화하고, 라인에서 작업자 작업을 개선하며, 대체 계획을 평가합니다.

파트 제조를 통한 생산 계획의 최적화

기계 가공업체를 하나의 시스템에서 제품 설계 및 어셈블리 계획 정보를 제공하는 데이터 기반 운영으로 혁신하십시오. 파트 계획, 제조 현장과의 연결 및 제조 리소스 라이브러리를 통해 생산 프로세스를 최적화할 수 있습니다.

디지털 방식으로 관리하는 제조 리소스

필요한 것을 빠르게 찾고 분류 시스템 전반에 걸친 강력한 검색 및 가져오기 기능을 활용해 제조 리소스를 효율적으로 관리하십시오. 사전 로드된 절삭 공구 데이터를 제공하므로 NX CAM 내에서 MRL(제조 리소스 라이브러리)에 직접 액세스할 수 있습니다. 공구 어셈블리를 작성하거나 공구 공급업체 카탈로그에서 데이터를 가져올 수 있습니다.

제조 현장에 대한 연결

하나의 플랫폼을 사용하여 계획과 생산을 연결합니다. CNC 기계, CMM, 로봇 등 제조 장비에 정확한 데이터를 직접 전달합니다. 기능 영역 전반에 걸쳐 전체 제조 프로세스 계획을 전달합니다. 어떤 제품이 어디에서 어떻게 제조되는지 명확히 밝힙니다. 모든 이해 관계자가 필요한 리소스를 파악하고 있습니다.

Next-generation collaboration with Teamcenter Share

Optimize your production and manufacturing processes with Teamcenter Share, a cloud-based collaboration solution with a seamless connection to Teamcenter Easy Plan software. Extend the reach of manufacturing planning-related data and processes beyond your internal teams to work smarter and accelerate innovation.