Bridging the gap between plant design methodology and implementation knowledge

Using Mechatronics Concept Designer and Tecnomatix, university makes mechatronic design methods and virtual commissioning tangible, enhancing education and industry cooperation

Johannes Kepler University

Established in 1966, the Johannes Kepler University (JKU) offers 60 fields of study, providing a multidisciplinary and practical education that is in line with current demands from industry and society. A fully academic mechatronics engineering course was established as early as 1990, making JKU a pioneer in the field of mechatronics. The university enjoys a favorable international reputation for its fundamental and application-oriented research.

http://www.jku.at/imdp- Headquarters:

- Linz, Austria

- Products:

- Mechatronics Concept Designer, NX, Tecnomatix

A successful knowledge transfer of model-based mechatronic design…is difficult to achieve by purely theoretical instruction. To bridge the knowledge gap between theoretical science and application-oriented education, we used Siemens products to build a mechatronic design demonstrator (MecDes), providing students with practical hands-on experiences.

Johannes Kepler University

Knowledge transfer from research to education

A variety of challenges including growing complexity and shorter innovation cycles is confronting machine and plant engineering. Using an interdisciplinary system model of the mechatronic system to create a digital twin of the machine or plant, model-based design allows concurrent design of the mechanical, electrical and software aspects. Particularly in large and complex designs, this approach is a promising methodology for meeting challenges such as complexity, quality, time and costs in product development. Engineers can use the digital twin to verify compliance with requirements following each step in the development without building and possibly destroying expensive prototypes. This approach prevents them from pursuing suboptimal design paths for too long and assures that the requirements can be met in short time.

Likewise, the digital twin of a machine or plant can be used to verify and optimize the control software code during virtual commissioning. The verification greatly improves software quality at the time of installation, substantially reducing the time spent performing on-site programming in the adverse environment of a factory floor during commissioning of the real system. As traditionally implemented at the end of a development cycle, required software modifications can be very time-consuming, stressful and costly. Model-based mechatronic design (MBMD) combines virtual commissioning with model-based design to perform permanent commissioning using the digital twin along the entire development phase, improving existing product development processes through closer integration of all disciplines involved. This methodology supports and facilitates development of products with excellent quality that reliably meet their requirements within a very short time.

“While model-based mechatronic design is a well-established research area in the academic environment, its promising theoretical approaches have not yet been implemented on a broad scale, especially in the conceptual design phase,” says Lukas Weingartner, research assistant at the Institute of Mechatronic Design and Production (IMDP) at Johannes Kepler University (JKU) in Linz, Austria. “It is therefore difficult to find tangible examples for education.” Such examples are particularly useful in engineering study programs, as their graduates will end up working in key positions in the industry, shaping its future.

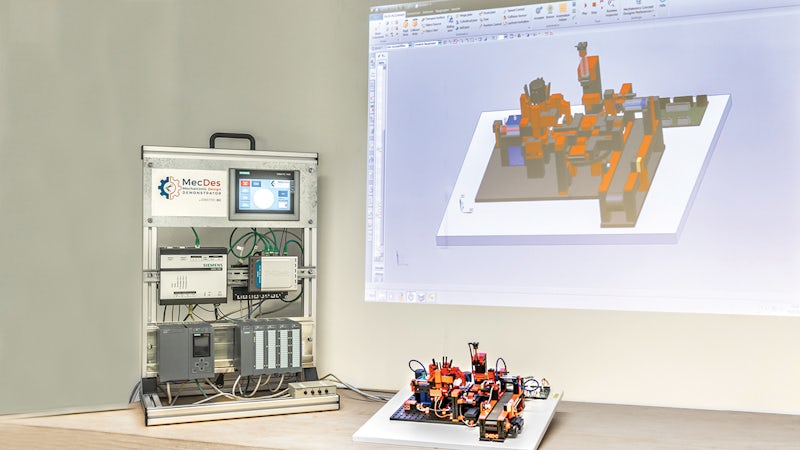

“Tell me and I will forget. Show me and I will remember. Let me do and I will understand.” This maxim is attributed to the ancient philosopher Confucius, but is applied today at JKU. “A successful knowledge transfer of model-based mechatronic design to students at engineering colleges and to engineers in companies is difficult to achieve by purely theoretical instruction,” says Dr. Peter Hehenberger, former Deputy Head of IMDP at JKU and initiator of the MecDes project. “To bridge the knowledge gap between theoretical science and application-oriented education, we used Siemens products to build a mechatronic design demonstrator called MecDes, providing students with practical hands-on experiences.”

Modeling and simulation: a central task

A central task in creating a model-based engineering environment that seamlessly covers all engineering phases is to identify, create and formally implement all models used consciously and unconsciously in product development. These may include geometric and kinematic models, the mathematical description of important system properties, for example the dynamic behavior of machines and plants, actuator/sensor models, a communication model for signal processing as well as control intelligence and logic models, a human machine interface (HMI) and a physical representation of the entire product or critical parts of it.

The actuator/sensor model is the pivotal interface between the computer-aided design (CAD) model and the programmable logic controller (PLC). The JKU scientists used a block-oriented simulation tool to mathematically define the interaction between sensor and actuator signals on the one hand and mechanical movements on the other. For communication, the MecDes uses the Ethernet and PROFINET communication standards

Model-based work using Mechatronics Concept Designer

The JKU scientists predominantly used product lifecycle management (CAD) software from Siemens to create the digital twin of a pneumatic machining center with automated internal material transport in a model-based mechatronic design approach. The effort involved concurrent engineering with parallel work in the mechanical, electrical and software engineering disciplines. For model-based design of the geometric and kinematic models on the machine level, they decided to use Mechatronics Concept Designer™ (MCD) software, part of the Siemens NX™ software portfolio for computer-aided design.

“Mechatronics Concept Designer supports our model-based mechatronic approach, synchronizing or overlapping traditionally sequential design phases,” says Martin Ahrens, research assistant at IMDP at the time the MecDes was designed. “Following the definition of a requirement, a systems designer can use MCD to create coarse blocks and enrich them with variables representing these requirements.

For example, if an object of a given size and mass needs to be transported from position A to position B within a given time, it is not necessary at this early stage to define the drive technology to be used in the final design. Before actually adding geometric detail, electrical and software engineers can use this model and the data it generates to dimension their components, to begin working on circuit diagrams and to start programming fundamental software routines. This approach enables engineers of the various disciplines to work concurrently and collaboratively as soon as all essential requirements are defined. It helps them design faster and with higher quality, reducing time-to-market and facilitating better decision making through concept evaluation. “The common system model can be used as a means of communication between the different disciplines,” says Professor Dr. Klaus Zeman, head of IMDP at JKU.

Concurrent design and verification work

Concurrently with mechanical and electrical design work, control code can be written and compiled to the PLC in all development phases of the machine or plant. To the extent that all requirements are specified and have been translated into functionality, this is also true for the graphic user interface (GUI) to be implemented on a touch-screen for manual control operations.

Above the machine level, the JKU scientists used the Process Simulate solution in the Tecnomatix® portfolio from Siemens to facilitate offline robot programming and fast simulation of the entire production cell. In order to make the MecDes powerful and flexible enough to be used for designing and simulating entire factories with many production cells, they added a further abstraction level using the Plant Simulation solution, also part of the Tecnomatix portfolio. “The ideas behind Industry 4.0 can only be of value if the methods used to make production adaptive are fully scalable,” says Weingartner. “Using Siemens Digital Industries Software products for the machine, cell and shop floor levels, we managed to program code for the PLC to control simulation models with full scalability.” To accomplish this, the scientists used the capabilities of Siemens’s Totally Integrated Automation (TIA) portal, a comprehensive environment for the development of control software to run on Siemens SIMATIC control equipment.

Real world and digital twin combined

Mechatronics Concept Designer supports simulation of real-time kinematic behavior. To include timing characteristics of the PLC and field bus components during permanent virtual commissioning, the compiled code is executed on a real PLC. A SIMBA field bus simulation box from Siemens is used to emulate the calculated signals of the field bus components in the virtual model, including their timing characteristics.

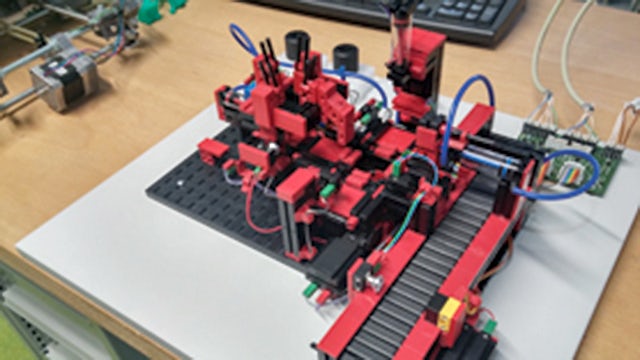

Using building blocks from an off-the-shelf training model kit, the team also built a prototypical physical model consisting of compressor, pneumatic devices, motors, other actuators, push-buttons, photo sensors, a drilling station, conveyor belts, and other components. In the MecDes, the control software can be used to drive either the computer model or the physical prototype, with a switch to toggle from one operating mode to the other. This allows software engineers to reiterate coding if the results are less than optimal. The software model and the real plant’s physical representation can run in parallel, controlled from the same PLC software, so deviations in their behavior can be detected.

The MecDes was built as a compact, portable unit so it can easily be used for educational purposes as required. It provides mechatronics students and design engineers with a deeper insight into mechatronic development methods and better comprehension of its relevance, as well as improved chances to achieve design success quickly and error-free. This not only promotes job identification but also demonstrates that a complete design is more than the sum of its parts.

Mechatronics Concept Designer supports our model-based mechatronic approach, synchronizing or overlapping traditionally sequential design phases. Following the definition of a requirement, a systems designer can use MCD to create coarse blocks and enrich them with variables representing these requirements.

Johannes Kepler University