자동차 엔지니어는 디지털 트랜스포메이션 여정을 배포하기 위해 어떤 전략을 사용할 수 있을까요?

자동차 엔지니어링 소프트웨어를 사용하여 시뮬레이션 및 테스트 전략을 구현하여 전기화, 자율성, 경량 설계, 안전, 시스템 통합, 승인 및 상호 연결성 문제를 해결합니다.

자율 주행 및 전기 혁명은 계속될 것입니다. 자동차 산업이 디지털 트랜스포메이션을 수용했지만, 그렇다고 해서 우리가 함께 정상에 도달한 것은 아닙니다. 혁신을 더 빠르고 효율적으로 엔지니어링하려면 사람, 기술 및 프로세스를 연결해야 합니다. 이 두 가지가 조화를 이룰 때 디지털 트윈의 완벽함과 제품의 완벽함 사이의 격차를 좁힐 수 있습니다.

Denso는 NX CAD와 Simcenter 3D 통합 프로세스와 CAE 템플릿을 사용하여 CAE 해석에 소요되는 시간을 최대 80%까지 단축했습니다. (덴소)

프랑스 제조업체인 PSA 푸조 시트로엥(PSA Peugeot Citroën)은 멀티피직스 접근 방식을 도입하여 배터리 팩을 두 배 더 빠르게 최적화하면서 비용을 절감했습니다. (PSA 푸조 시트로엥)

Honda 엔지니어가 소음이 어디에서 오는지 식별하는 데 3-4시간이 걸렸습니다. 이제 그들은 매우 정밀하게 15분 안에 이 작업을 수행할 수 있습니다. (혼다)

자동차 엔지니어링 소프트웨어를 사용하여 시뮬레이션 및 테스트 전략을 구현하여 전기화, 자율성, 경량 설계, 안전, 시스템 통합, 승인 및 상호 연결성 문제를 해결합니다.

자동차 성능 엔지니어링은 모든 개발 단계에서 고급 시뮬레이션 및 테스트 솔루션을 사용합니다. 이를 통해 초기 설계 결정을 내리고, 상충되는 차량 특성의 균형을 맞추고, 시장 출시 시간을 단축하고, 비용을 절감할 수 있습니다.

Simcenter는 엔지니어의 디지털 여정을 지원하는 예측 시뮬레이션 및 테스트 솔루션을 제공합니다. 최첨단 자동차 엔지니어링 소프트웨어 및 도구, 업계 전문 지식 및 고객 지원을 통해 Simcenter는 엔지니어링 팀이 디지털 트윈의 잠재력을 최대한 활용할 수 있도록 지원합니다.

지금 Simcenter 기계 시뮬레이션을 체험하고 기계 설계를 가속화하십시오. CAD 설계에 시뮬레이션을 추가하여 제품 변경 사항을 검증하고, 자동차 모션 시뮬레이션의 맥락에서 유연한 차체 모션을 생성하고, 대형 시뮬레이션 어셈블리에서 협업 작업하고, 테스트 결과의 상관 관계를 분석하여 시뮬레이션 결과를 확인 및 검증하는 방법을 알아보십시오.

사용자 인식은 매우 중요합니다. 이는 Simcenter가 얼마나 잘 작동하고 있는지, 그리고 지속적인 소프트웨어 릴리스 주기가 고객에게 반향을 일으키고 있는지 여부를 반영합니다.

개발과 운영을 디지털로 연결해 차량을 스마트하게 만드는 것이 차세대 기술 혁명입니다. HiL 시뮬레이션을 사용해 주요 보정 값을 사전 정의해 실제 차량 테스트 횟수를 40% 줄일 수 있었습니다.

엔지니어링 컨설팅 서비스를 통해 엔지니어링 디지털 트윈을 구축할 수 있습니다.

Siemens Xcelerator Academy가 Simcenter를 마스터하고 생산성을 빠르게 높이는 데 어떻게 도움이 되는지 알아보십시오.

Simcenter 전문가 커뮤니티에 가입하여 지식을 넓히십시오!

차량 성능은 가속, 배터리 범위, 안전, 공기 역학 및 물 관리, 첨단 운전자 보조 시스템(ADAS), 에너지 및 열 관리, 소음, 진동 및 불쾌감(NVH) 및 음향, 강도 및 내구성, 차량 제어 및 차량 핸들링과 같은 측면을 포함하여 차량의 전반적인 기능, 효율성 및 기능과 관련이 있습니다.

자동차 성능 엔지니어링은 비즈니스 요구 사항에 따라 구동되며 지속적인 가상 테스트 및 모니터링 루프를 통해 엔드 투 엔드 시스템 최적화를 제공합니다. 자동차 제조업체와 공급업체는 시프트 레프트 전략을 사용하여 개발 주기 초기에 잠재적인 문제를 발견하여 더 나은 비즈니스 가치를 제공하는 것을 목표로 합니다. 설계 프로세스 초기에 시뮬레이션을 사용하고 제품이 요구 사항을 충족하는지 가상으로 테스트함으로써 문제를 조기에 감지하고 이해할 수 있는 디지털 트윈에서 수정할 수 있습니다. 또한 설계 변경이 더 쉽고 중단이 적은 설계 단계 초기에 설계 대안을 탐색할 수 있습니다.

다중물리 시뮬레이션은 시스템 또는 시스템의 여러 동시 물리적 현상과 이들 간의 상호 작용을 분석하는 것을 말합니다. 소비자 요구와 비즈니스 요구 사항에 따라 다중물리 자동차 엔지니어링 소프트웨어는 안전한 고성능 제품을 더 빠르게 설계하는 것을 목표로 합니다. 이를 통해 복잡성을 모델링하고, 실제 조건에서 작동하는 제품의 가능성을 탐색하고, 개발 주기 초기에 잠재적인 문제를 발견할 수 있습니다.

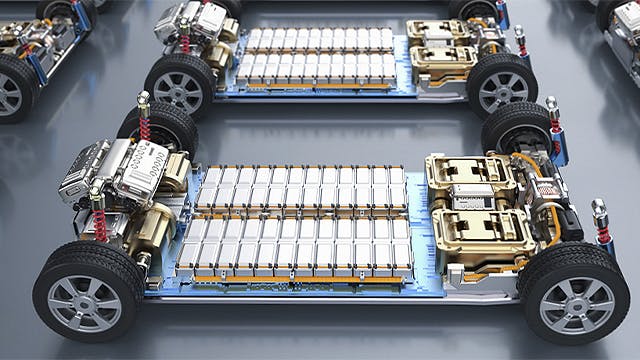

예를 들어, 차량 배터리 개발, 설계 및 엔지니어링 팀은 전기화학, 전기, 열 및 구조 엔지니어링을 통합해야 합니다. 이러한 개별 속성을 대상으로 하는 격리된 캠페인을 실행하면 중복되고 때로는 충돌하는 모델과 데이터 세트가 생성됩니다. 대신, 올인원 다중 물리 접근 방식을 사용하면 구성 요소가 다른 구성 요소와 통합될 때 어떻게 작동하는지 정확히 이해할 수 있으며 첫 번째 프로토타입도 계획대로 작동하는지 확인할 수 있습니다.

프로토타입에서 자동차(시스템) 테스트를 수행하던 시대는 오래 전에 지나갔습니다. 오늘날 개발은 V-사이클의 끝에서 멈추지 않습니다. 대신, 과거 데이터, 테스트 데이터 및 사용 중인 차량의 데이터를 사용하여 차량 특성과 성능 간의 관계를 정의하는 테스트 기반 모델을 생성함으로써 무한 루프를 계속합니다.

좋은 예는 MBST(모델 기반 시스템 테스트 )입니다. MBST는 가상 모델, 가상 물리 시스템 및 물리적 프로토타입의 세 가지 핵심 솔루션을 사용하는 엔지니어링 프레임워크입니다. 테스트 데이터를 활용하여 시뮬레이션 모델을 구축, 검증 및 개선하고, 다양한 시나리오에서 XiL을 통해 상호 작용을 식별하고, 물리적 프로토타입을 위한 시뮬레이션 모델로 테스트 데이터를 향상시킵니다. MBST를 사용하는 제조업체는 더 효율적이고 빠르며 데이터 전송 또는 후처리 오류를 방지할 수 있습니다.

또 다른 뛰어난 예는 가상 프로토타이핑입니다. 가상 프로토타이핑은 물리적 프로토타입을 제작하기 전에 차량 조립 대안을 탐색할 수 있는 효율적인 테스트 방법입니다. 특히 NVH 성능을 다루고 구성 요소 기반 전송 경로 분석(TPA)을 사용하여 다양한 설계를 신속하게 평가하여 문제를 조기에 감지하고 제어하여 비용을 절감합니다.

전통적인 설계 및 엔지니어링 방법은 오늘날의 복잡한 워크플로와 어려움을 겪고 있습니다. 인공 지능(AI) 과 머신 러닝(ML)을 활용하면 의사 결정을 가속화하고 엔지니어링 팀의 생산성을 높이며 더 짧은 시간 내에 혁신적인 제품을 개발할 수 있습니다. 개발 주기의 모든 단계에 적합한 Simcenter는 인공 지능을 적용하여 과거 데이터를 활용하고, 실수를 방지하고, 해석 속도를 높이고, 자신 있게 설계를 최적화할 수 있는 프레임워크를 제공합니다.

예를 들어, 자율 주행 차량 시스템에서 AI와 ML은 인간의 행동을 기계 인식에 포함시키는 데 사용됩니다. 현재의 자율 주행 차량 인식 시스템은 특히 표준 조건에서 인간의 감각 능력과 거의 일치하지만 극한의 날씨와 복잡한 시나리오에서는 부족합니다. Simcenter의 시나리오 생성 프로세스는 OEM 및 AV 공급업체를 위한 중요한 시나리오를 생성하여 SOTIF(Safety of the Intended Functionality)와 같은 안전 표준을 준수하는 데 도움이 됩니다.

차량 시스템을 통합하는 유일하게 지속 가능한 방법은 설계와 엔지니어링을 완전한 생태계로 접근하는 것입니다. 이를 통해 제조업체는 요구 사항이 변경됨에 따라 워크플로를 신속하게 재설계하고 재사용할 수 있으며 여러 도메인 간에 속성을 절충할 수 있습니다. 프로세스 수준에서는 PLM(제품 라이프사이클 관리) 시스템과의 연결을 유지하면서 요구 사항을 충족하여 한 도메인의 변경 사항이 전체 시스템에 반영되도록 하는 것이 중요합니다. 차량 개발의 모델 기반 시스템 엔지니어링(MBSE) 접근 방식은 시스템 엔지니어링을 개발 조직의 나머지 부분과 연결하여 협업 및 의사 결정을 개선합니다.

전기 드라이브 엔지니어링을 예로 들어 보겠습니다. e-드라이브는 전기 모터, 기어박스 및 파워 일렉트로닉스로 구성됩니다. 서로 다른 분야의 여러 전문가가 협력하여 효율적인 통합 전기 구동을 달성해야 합니다. 따라서 과거의 전통적인 개발 사일로를 떠나 부서 간 및 도메인 간 시스템 엔지니어링을 허용하는 것이 중요합니다. MBSE 및 디지털 트윈 애플리케이션을 통해 재사용 가능한 통합 워크플로우를 갖춘 커넥티드 엔지니어링 접근 방식만이 제조업체에 제품뿐만 아니라 개발 프로세스의 급격한 전기 자동차 엔지니어링의 복잡성을 관리할 수 있는 자동차 엔지니어링 소프트웨어 툴체인을 제공합니다.