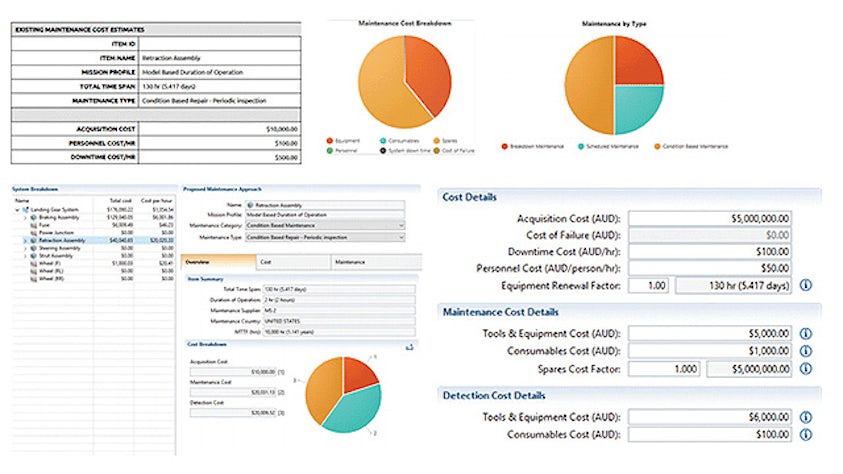

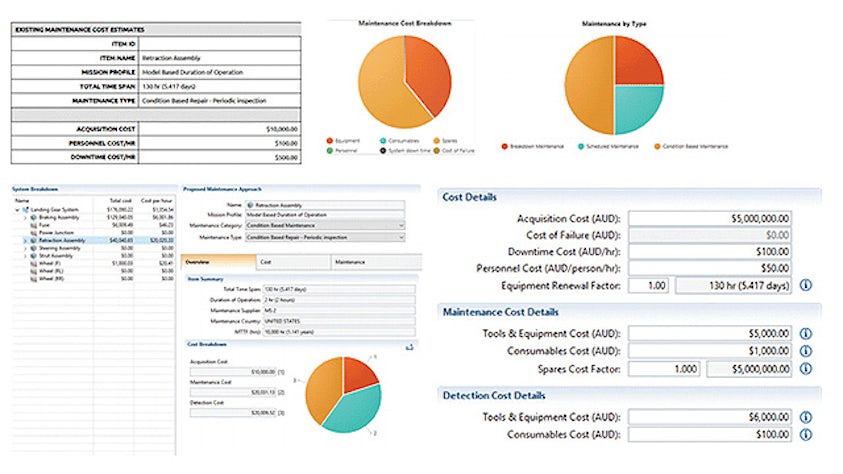

設計構成、関連するミッション・プロファイル、動作環境、保守手法に基づいた、保守コストの解析とトレード・スタディを可能にします。資産のシステム、サブシステム、主要アセンブリの正確なコスト見積もりを確立し、これを使用して代替保守概念の保守関連コスト (ライフサイクル全体) を比較します。

エンジニアが、特定の設計状態やオペレーション構成に合わせて調整できるシミュレーション解析に基づいて、製品ライフサイクルの各段階で設計とサービスの推奨事項を生成できるようにします。

設計構成、関連するミッション・プロファイル、動作環境、保守手法に基づいた、保守コストの解析とトレード・スタディを可能にします。資産のシステム、サブシステム、主要アセンブリの正確なコスト見積もりを確立し、これを使用して代替保守概念の保守関連コスト (ライフサイクル全体) を比較します。

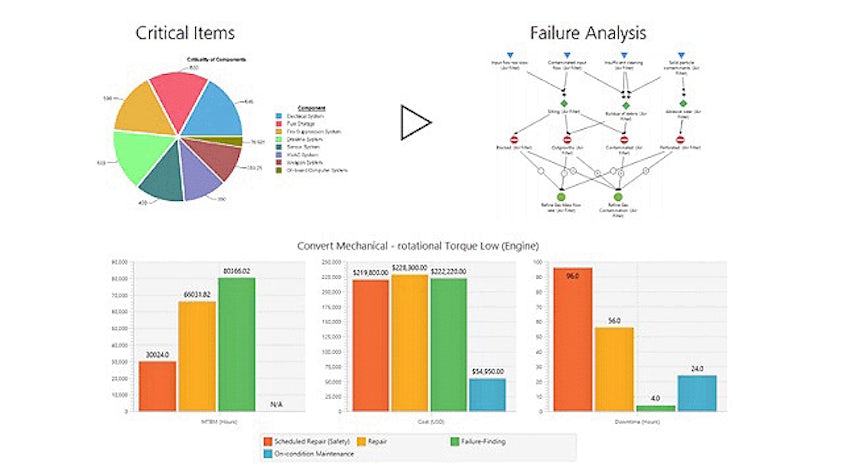

バックフィットRCM (信頼性中心保全) 手法を使用した構成管理プロセスに基づいて、信頼できないアイテムに優先順位を付け、そのパフォーマンスを最適化することで、パフォーマンスの低下しているコンポーネントの保守作業を見直します。MERは、複雑なプラットフォームの維持につながるため、コスト面、スケジュール面、技術面で潜在的なメリットが得られます。

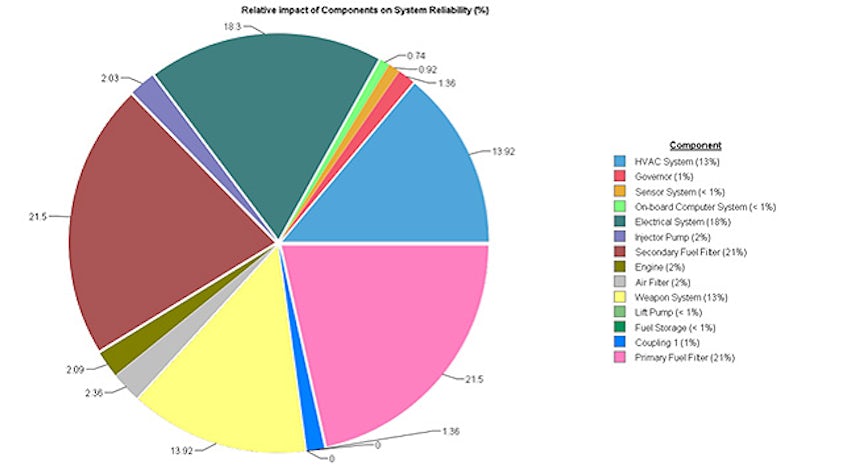

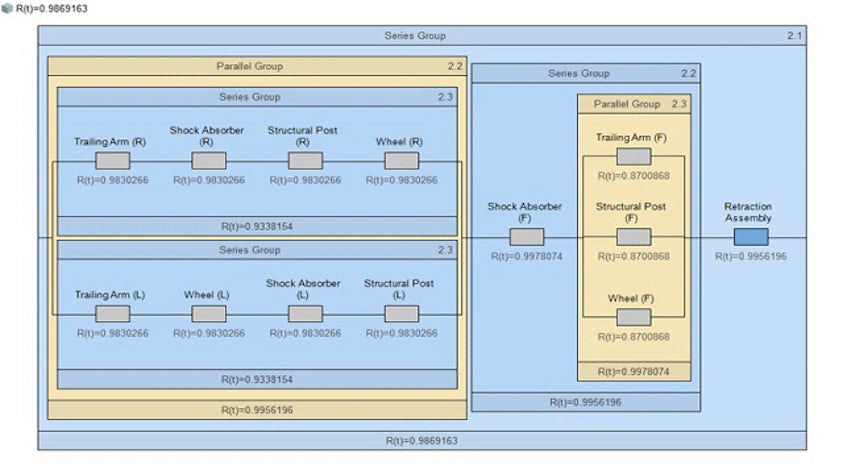

構成要素であるコンポーネントや部品に至るまで、システム全体の信頼度を理解します。システムのエンジニアリング段階に具体的な目標を要件として使用することで、エンジニアは自信をもって、信頼度の目標を満たすアイテムを設計および取得できます。それらのアイテムをより大きなシステムに統合したときにも信頼度目標から大きく逸脱することがないため、再設計のリスクとコストを低減できます。

デジタル・リスク・ツインから直接信頼性解析を生成し、リアルタイムのコンテキストに沿った解析を可能にして設計の信頼性を把握することができます。直列冗長、並列冗長、スタンバイ冗長、K/N、除外など、幅広い複雑な構成をモデル化します。強力な計算エンジンを使用して、信頼性、可用性、保守性、ライフサイクル・コストを計算します。

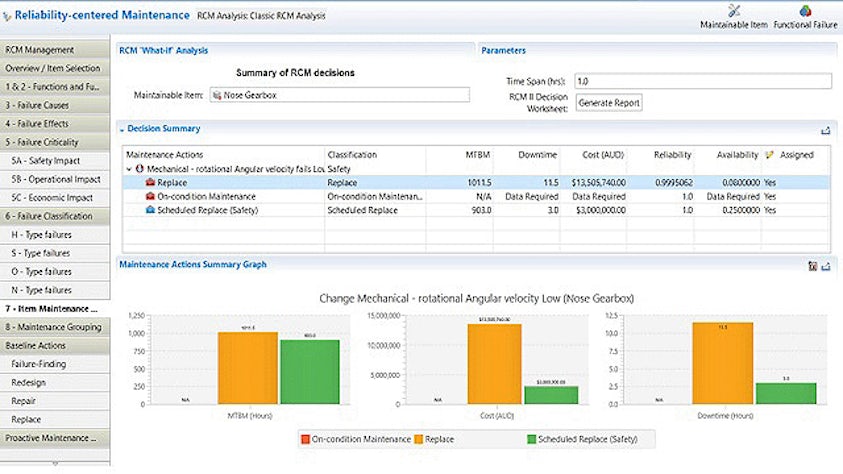

RCM解析を実行し、予想される使用法と期待される信頼性に基づいて最適な保守スケジュールを特定します。組織のエンジニアリング・プロセス内に統合するように構成可能な、代替メンテナンス手法の技術的実現可能性の評価とコスト比較を行います。業界標準 (MSG3、MIL 3034、SAE-JA1012など) との一貫性を維持し、資産ライフサイクルの各段階で効率的かつ費用対効果の高いものにします。