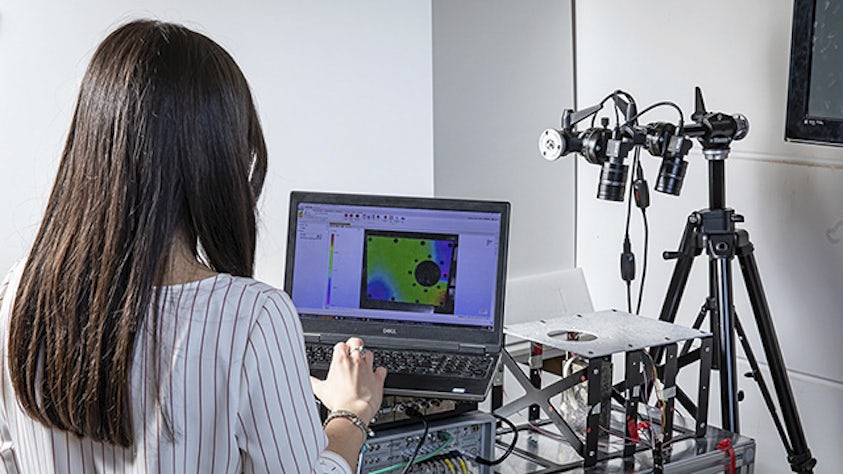

デジタル画像相関 (DIC) は、デジタルカメラの画像を使用して、3Dフルフィールド・データの変位、ひずみ、加速度を測定する非接触光学測定技術です。デジタル画像相関は、工学的測定に革命をもたらしました。大学で芽生えた好奇心に端を発し、産業界に受け入れられた技術へと進化しました。

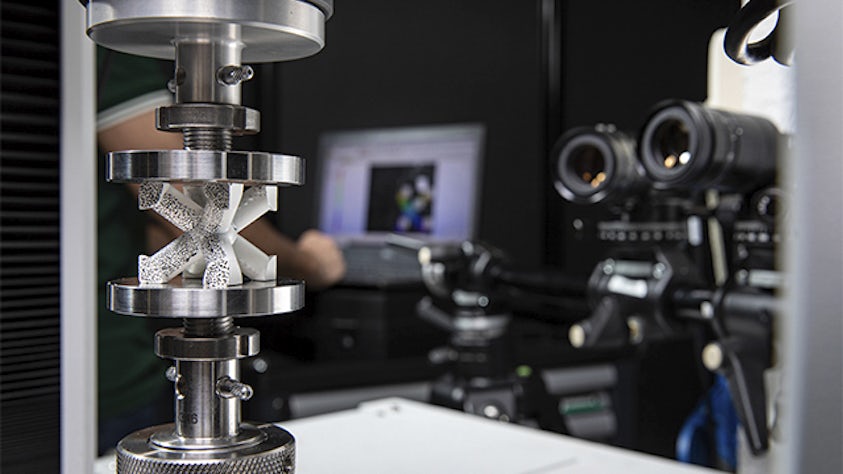

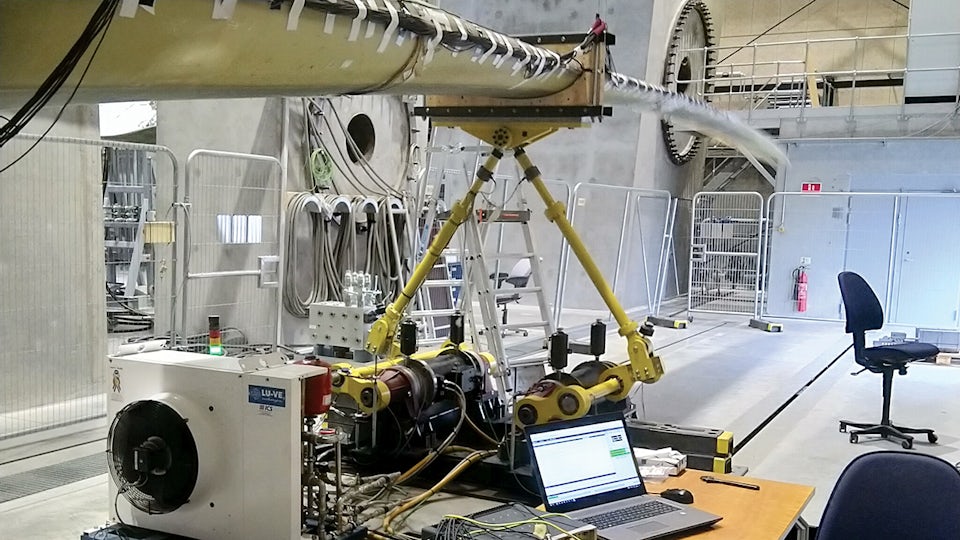

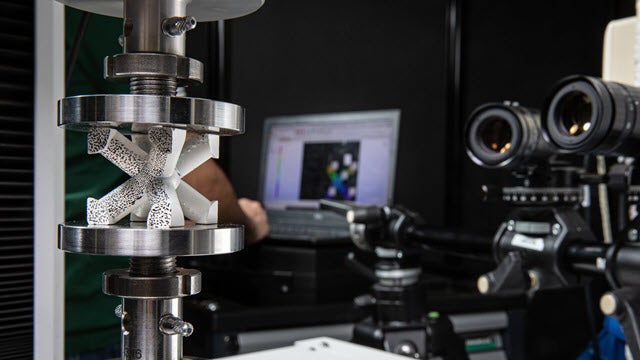

材料工学において引張、ねじり、曲げ、複合荷重など、多くの試験に使用できます。また、静的アプリケーションと動的アプリケーションの両方の構造試験にも使用できます。

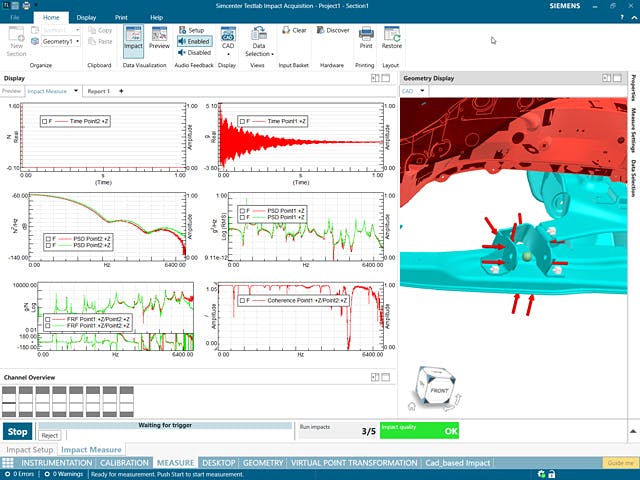

シーメンスのソリューションには、画像の変化に基づいて3Dフルフィールドを測定するための最新の追跡・画像登録技術が組み込まれています。美しい色鮮やかな画像の背後には、正確で信頼性が高く、定量的な3Dフルフィールド・データがいたるところに存在しており、3D有限要素解析の結果と簡単に一致します。センサーによるポイント測定と比較して、DICは限られた計測時間でより多くのインサイトを提供します。これらの結果を使用することで、新しい革新的な材料の機械的特性を正確に特定し、定量化された結果に基づいてシミュレーション・モデルの正確性と信頼性を高め、コンポーネントとシステムの構造検証試験を加速させて、より迅速でレスポンシブな開発サイクルを実現できます。