部品の配置とネスティング

部品の位置を正確に制御し、ビルド・ボリューム内で効率的な自動ネスティングを行うことにより、部品を効率的に印刷することができます。これを行うため、NXには、ビルドトレイを効率的に操作するための統合ツールが付属しています。NXを使用すれば、部品を手動で配置する場合でも、統合された2D/3Dネスティングで自動的に配置する場合でも、目標とする効率性と品質を実現することができます。

アディティブ・マニュファクチャリング (AM) プロセスにとって重要なことは、適切な準備作業です。シーメンスのビルド準備ソリューションはNX CAD/CAM環境に統合されているため、ファイルを変換したり、コストのかかるビルド・セットアップ作業をやり直したりすることなく、部品設計の変更内容を製造セットアップ・データまでシームレスに反映させることができます。

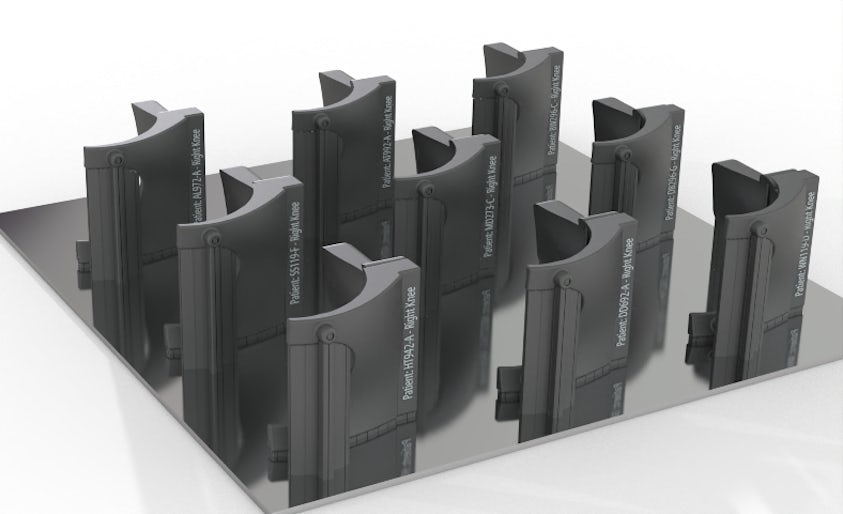

部品の位置を正確に制御し、ビルド・ボリューム内で効率的な自動ネスティングを行うことにより、部品を効率的に印刷することができます。これを行うため、NXには、ビルドトレイを効率的に操作するための統合ツールが付属しています。NXを使用すれば、部品を手動で配置する場合でも、統合された2D/3Dネスティングで自動的に配置する場合でも、目標とする効率性と品質を実現することができます。

AM生産の追跡と認証用の印刷マークの生成を詳細に管理することが重要です。多くの場合、ビルドトレイ内の部品を一意のマーキングや番号でシリアル化する必要があります。これを行うには、NX AMビルド準備システム内で一意の識別子を適用します (手動、プログラム、またはスプレッドシート・インターフェイスによる適用)。

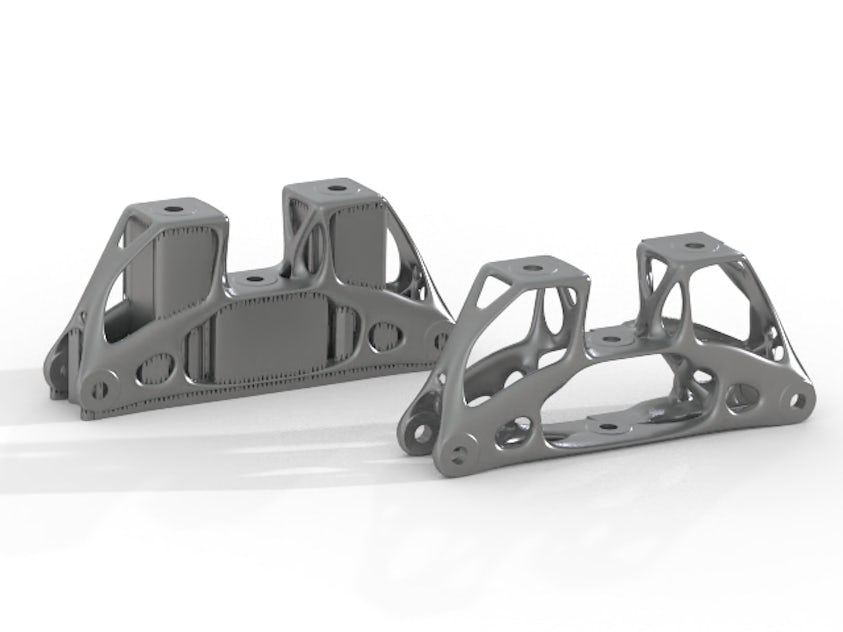

高品質な支持構造を生成することができます。多くのアディティブ・マニュファクチャリング技術では、高品質な支持構造が高品質なビルドのベースになっています。NXでは、支持構造の自動生成ソリューションだけでなく、カスタムの支持構造を設計するためのNX CADソリューションも使用することができます。この緊密な統合機能は、AMに関わるすべてのユーザーにとって、品質が最優先される完成部品を印刷する際の大きなメリットになります。

会社:Unlimited Tomorrow

業界:医療機器 / 製薬

開催場所:New York City, New York, United States

シーメンスデジタルインダストリーズソフトウェア:NX

実用的な産業用アディティブ・マニュファクチャリング設計のための専門ソリューションをご覧ください。