オブジェクト指向の3Dシミュレーション環境でのモデリング

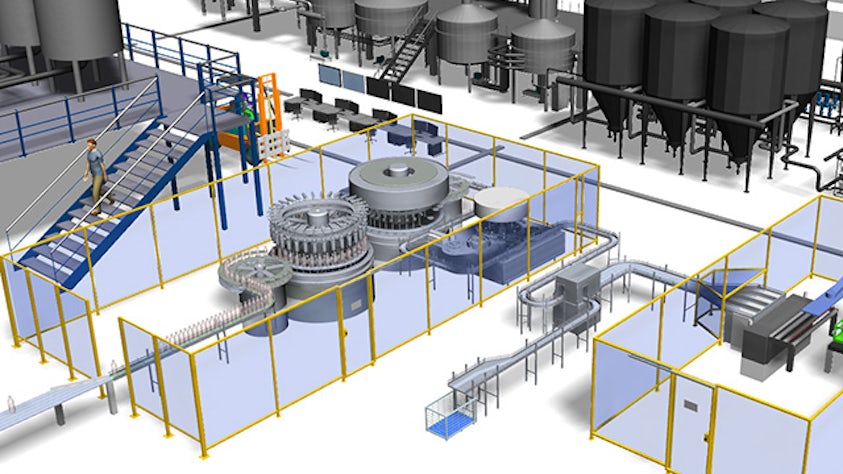

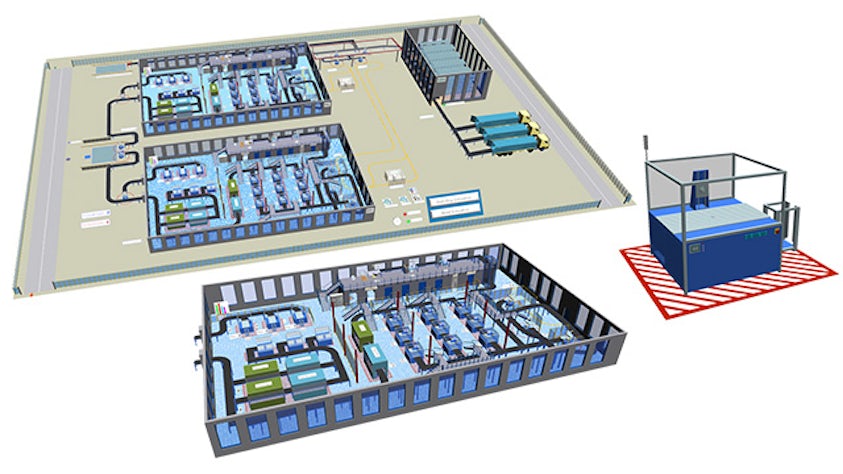

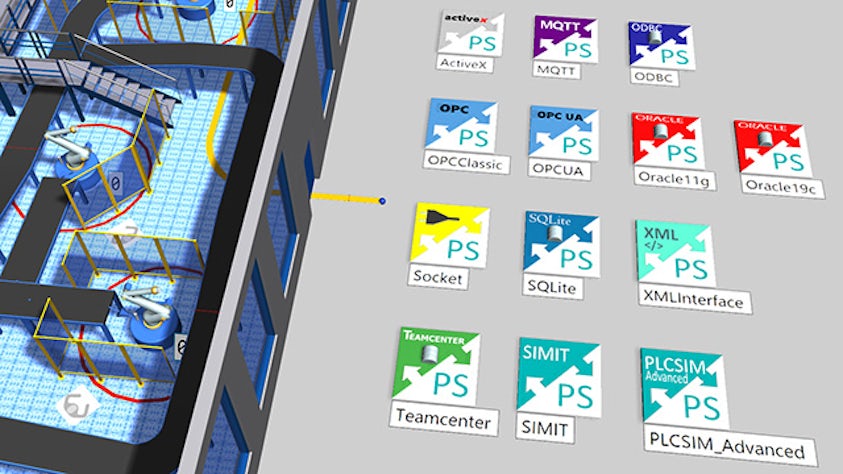

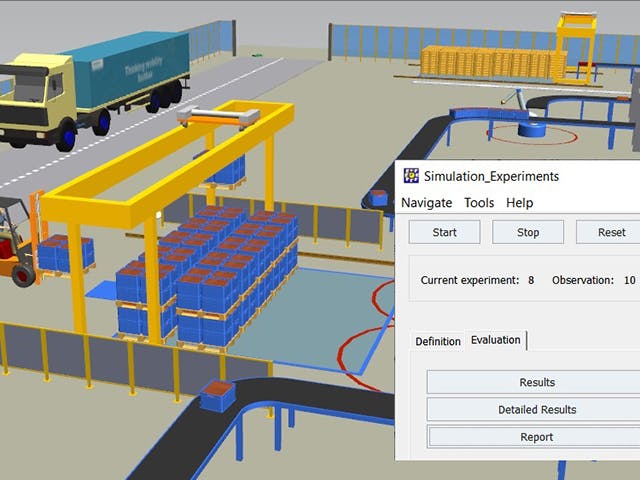

強力なオブジェクト指向アーキテクチャとモデリング機能を使用して、生産施設、ライン、およびオペレーションの適切に構造化された3D階層設計モデルを作成し、離散および連続製造プロセスの迅速かつ効率的なモデリングを実現します。

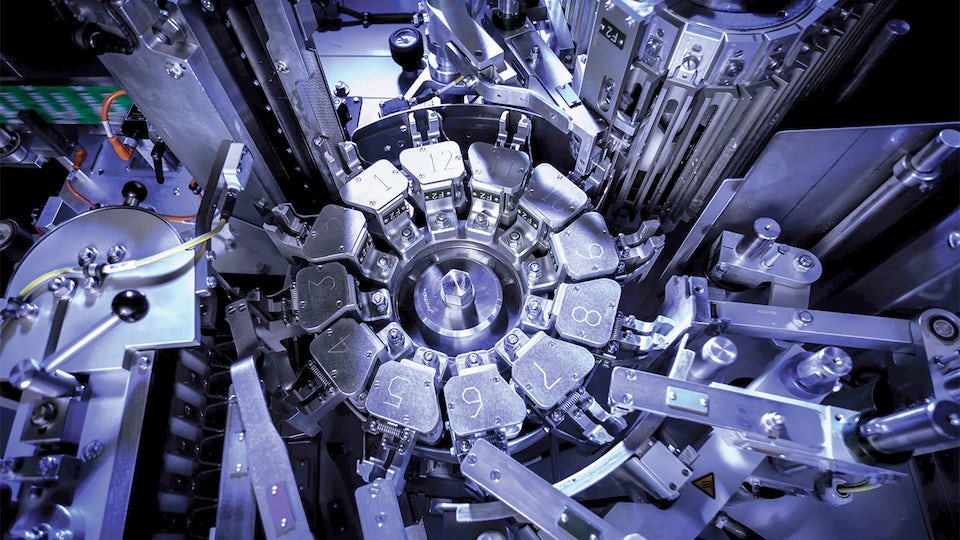

付属のライブラリまたは外部CADデータを使用して3Dにより構築および視覚化します。3Dモデリング用のJTデータ形式とシーメンスのダイレクト・モデル・テクノロジーを活用することで、シミュレーションや解析のニーズを損なうことなく、大規模な3Dシミュレーション・モデルを効率的にロードし、リアルに視覚化することができます。