高度な5軸の機械加工オペレーションを実現

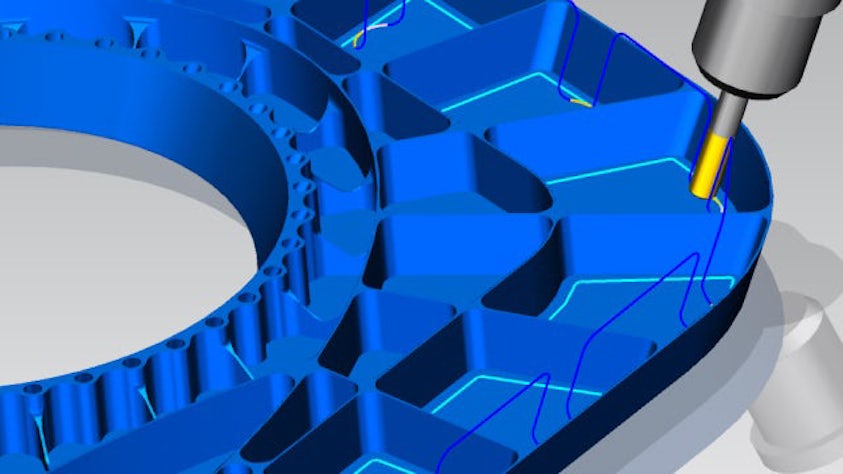

正確な工具軸制御と自動衝突回避を提供する最新の多軸ツールパスを活用します。

多軸高速粗加工であるアダプティブ・ミル加工は、機械加工時間を最大で60%短縮できます。滑らかな仕上げ方法は、部品の自然な形状に従うことができ、優れた仕上げを実現します。

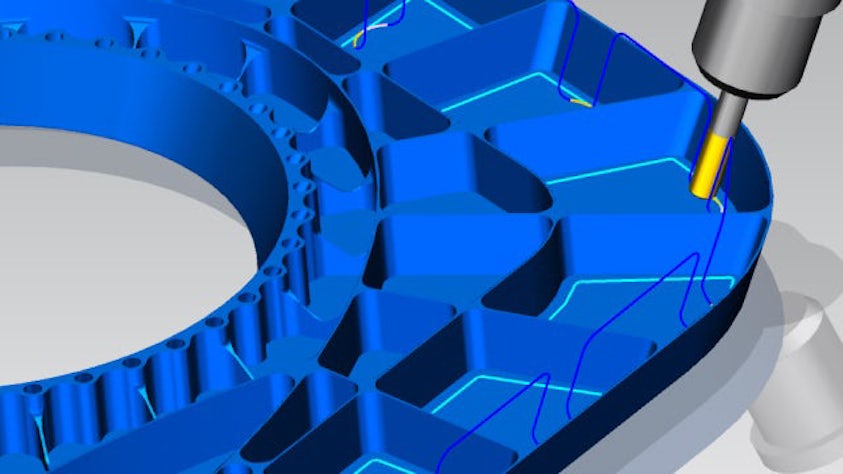

バレル工具は、より大きな工具噛み合いを可能にし、より短い機械加工サイクルでより高い部品品質を可能にします。

正確な工具軸制御と自動衝突回避を提供する最新の多軸ツールパスを活用します。

多軸高速粗加工であるアダプティブ・ミル加工は、機械加工時間を最大で60%短縮できます。滑らかな仕上げ方法は、部品の自然な形状に従うことができ、優れた仕上げを実現します。

バレル工具は、より大きな工具噛み合いを可能にし、より短い機械加工サイクルでより高い部品品質を可能にします。

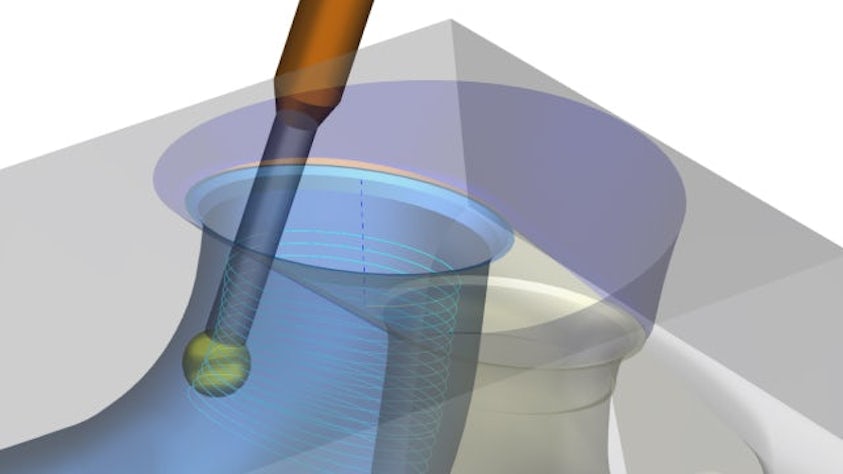

5軸チューブミル加工は、エンジン・ブロックのポートなど、中空で幅の狭いフィーチャのプログラミングを劇的に簡素化します。

この特殊なオペレーションを使用して、最小限の入力で粗加工と仕上げの両方の多軸加工オペレーションを生成します。

単一のツールパスで全領域を安全に加工し、加工効率と精度を向上させます。

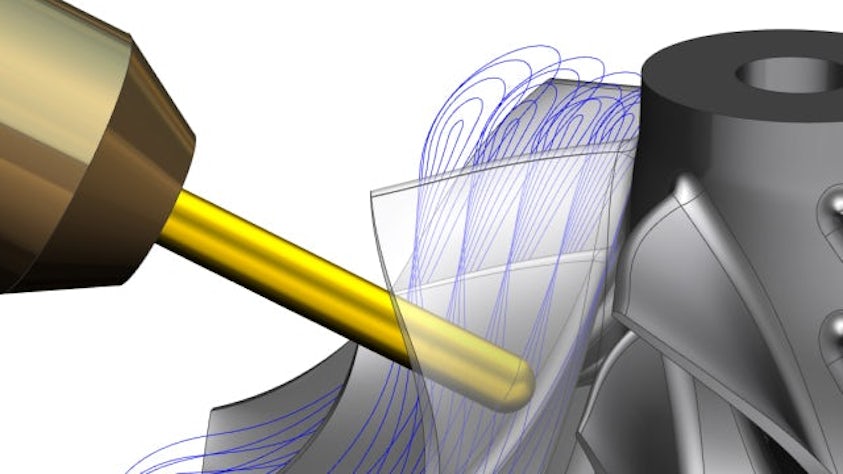

特殊な5軸NCプログラミング・オペレーションにより、ブリスクやインペラーなどの複雑なマルチブレード回転部品のプログラミングを簡素化します。

同時5軸粗加工と自動レストミリング (削り残し部加工) により、ブレード間の材料を除去します。ハブ、ブレード、スプリッターを仕上げるには、カットパターン、ツールパスのスムージング、エッジの工具軸の安定化を正確に制御することにより、最適化されたツールパスを使用します。

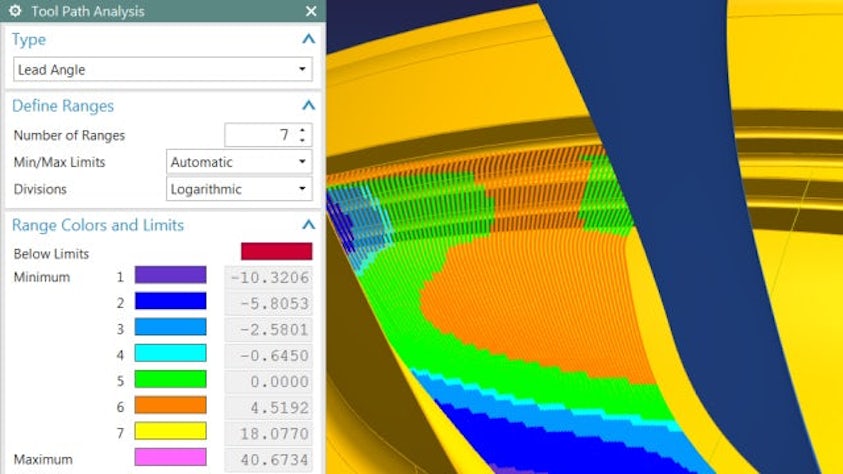

5軸機械加工中の複雑な機械挙動を解析するには、次のような多軸ツールパス特性を視覚化します。

オペレーション全体にわたって切削条件を検証することで、複雑な部品を最初から正しく加工することができます。

会社:Heiwa Sangyo

業界:自動車 / 輸送機器, 航空宇宙 / 防衛

開催場所:Funabashi City, Chiba Prefecture, Japan

シーメンスデジタルインダストリーズソフトウェア:NX