アディティブ・マニュファクチャリングを産業化するためのソリューション

シーメンスの堅牢なソフトウェア・ポートフォリオにより、設計から製造まで、アディティブ・マニュファクチャリングの工程全体を実行することができます。アディティブ・マニュファクチャリングの産業化について詳しくは以下をお読みください。

アディティブ・マニュファクチャリング用の設計

高品質のアディティブ・マニュファクチャリング (AM) プロセスを実現するには、なによりもまず高品質な設計ありきと言えます。AMであれば、最適な表面や格子構造など、複雑な構造であっても製造が可能です。シーメンスのアディティブ・マニュファクチャリング・ソリューションを使用すると、複雑な形状の設計や印刷を大規模に行うことができます。

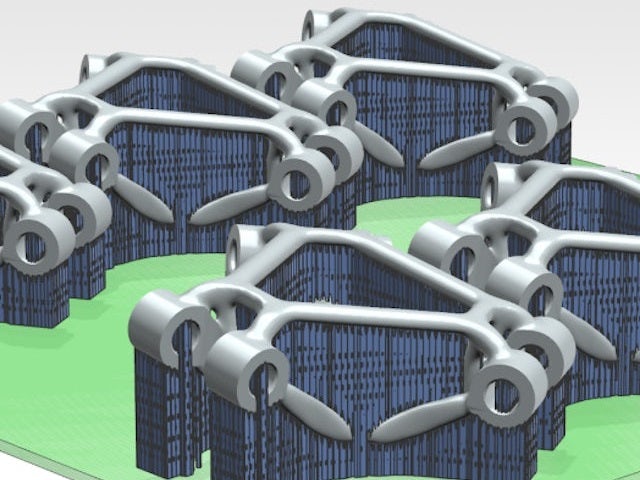

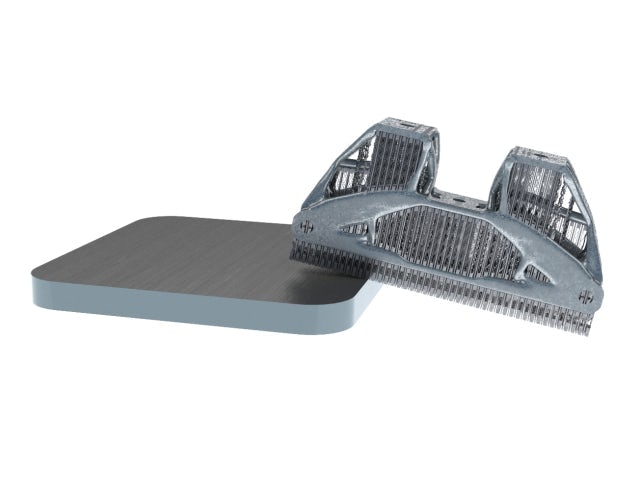

印刷ビルドの準備

AMプロセスで高品質な作業を効率的に行うには、適切なセットアップを行う必要があります。NXの高度な統合ビルド準備ツールを使用すると、最も効率的な方法でビルドトレイに部品を配置して方向を調整することができます。

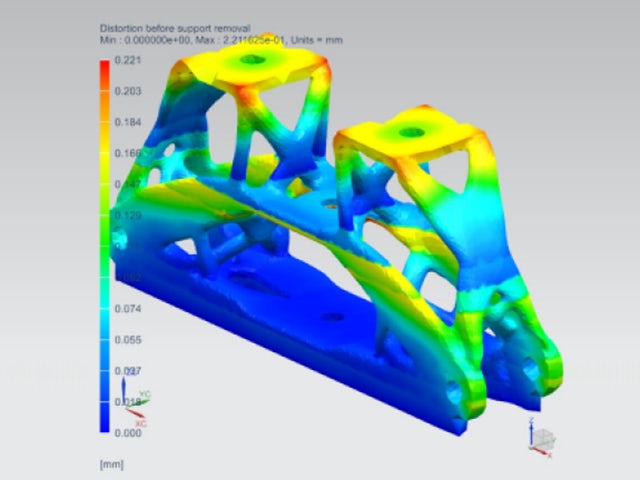

ビルド・シミュレーション

ビルドプロセスをシミュレーションすることにより、高品質の3Dプリントを大規模に生成することができます。NXには、ビルド方向の最適化ツールやメソスケールの堆積経路の最適化ツールなど、初回から正確な印刷を行うための各種ツールが付属しています。

各種ハードウェアとの接続

シーメンスNXを使用すれば、さまざまな3Dプリント用ハードウェアに接続することができます。接続できるシステムとしては、平面粉末床システム、フィラメント堆積システム、マルチマテリアル・システム、多軸システムなどがあります。

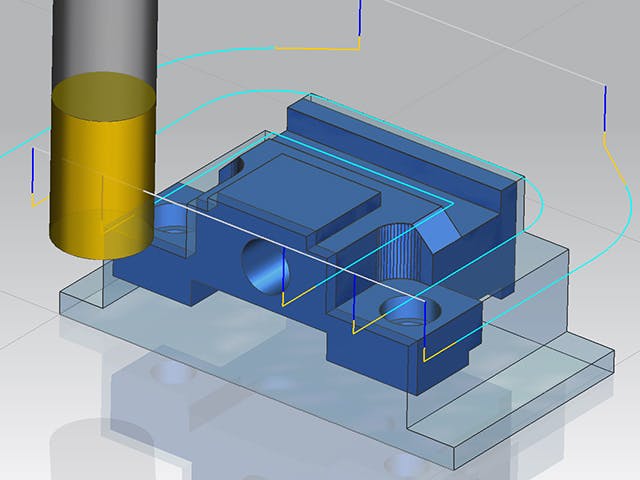

印刷後の処理

3Dプリント作業を産業化するには、堅牢な後処理ソフトウェアが必要です。印刷工程は、アディティブ・マニュファクチャリングの最終工程ではありません。粉末の除去、ビルドトレイからの部品の取り外し、後工程の機械加工などは、すべてAMプロセス全体を構成する作業です。当社のAMソリューション・セットは、これらすべての作業に対応しています。

プロセス管理

アディティブ・マニュファクチャリング工程の効率を最大化するには、プロセスを適切に管理する必要があります。注文から出荷までの一連のプロセスだけでなく、材料の管理や機械のスケジュール設定などについても管理する必要があります。シーメンスは、あらゆる規模の企業にソリューションを提供し、AMプロセス全体の効率を最大化しています。これにより、アディティブ・マニュファクチャリングに対する投資のROIが最大化されます。

LimaCorporate社

NXの3Dプリントでインプラントを設計

会社:LimaCorporate社

開催場所:イタリア、ヴィラノヴァ、サン・ダニエーレ・デル・フリウーリ

シーメンスデジタルインダストリーズソフトウェア:NX

サイズ:Medium

関連するNX for AM製品を確認する

実用的な産業用アディティブ・マニュファクチャリング設計のための専門ソリューションをご覧ください。