高度な設計自動化機能を活用して競争力を高めましょう

ワイヤー・ハーネス設計

ワイヤー・ハーネス設計エンジニアは、設計意図を効果的に把握し、検証済みで詳細なハーネス設計を迅速かつ正確に作成することができます。

ワイヤー・ハーネス製品エンジニアリング

Capitalは、自動化されたワイヤー・ハーネス・エンジニアリング、検証、およびレポートの機能を提供し、ハーネスエンジニアが製品データを効率的に準備することを可能にします。

ワイヤー・ハーネスのコスト計算

Capitalのワイヤー・ハーネス・コスト・モデリング機能により、エンジニアは現実的なコスト生成と正確な見積もりを可能にする包括的なモデルを作成することができます。

Capitalは、エンジニアがコスト削減と品質向上を実現できるよう支援します

デジタルデータの連続性と再利用可能な知的財産 (IP) を活用することで、新製品の導入時間を短縮することができます。デジタルツイン技術による自動化とシミュレーションを応用して、設計を最適化し、製品品質を向上させましょう。

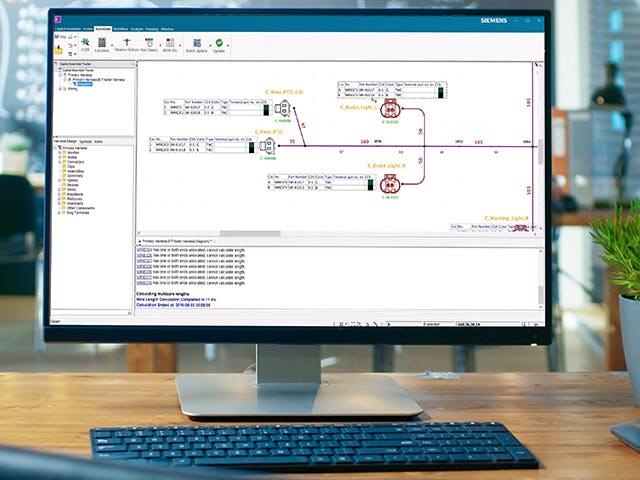

知的財産 (IP) を保護するコスト・モデリング

ハーネスは、入念に評価された、競争力のあるコストで製造できることが重要です。これは難しい課題です。プロジェクトの期間や利幅の縮小が続くなか、設計内容や銅の価格などの可変要素が急変する可能性があるからです。変動を考慮する必要があるため、原始的なコスト計算方法で的確に把握することは不可能です。Capitalは、コスト計算を自動化するための最適な専用ソリューションを提供します。このソリューションの正式なフレームワークとプロセスを実装することで、材料費と労務費の正確なコスト計算を迅速に生成することができます。

Capitalには、完全に拡張可能なコスト・モデリング機能が含まれています。これにより、知的財産 (IP) が保護されるとともに、コスト計算エンジニアは包括的なモデルを作成できるようになります。これらのモデルを利用して、現実的なコスト生成によって正確な見積もりを作成するために必要な詳細を把握します。このデータは「デジタル・スレッド」となり、これらのコスト計算モデルを製造フローの関連ツールで消費および再利用できるようになります。

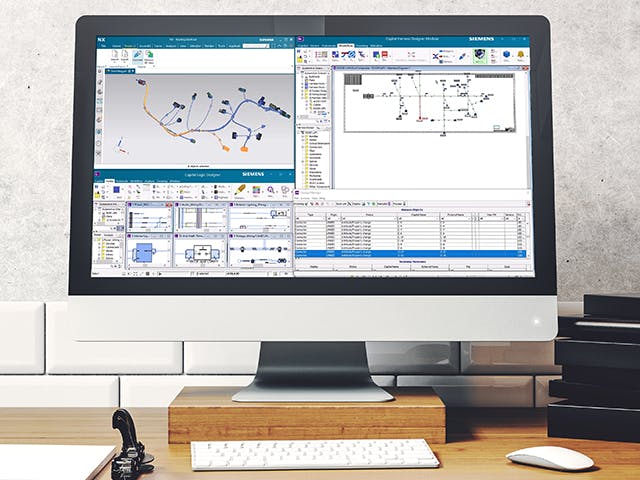

強力でグラフィカルなハーネス設計環境

ハーネス設計エンジニアは、ワイヤー・ハーネスの設計意図と要件を正確に把握して記述した詳細な図面を作成する必要があります。Capitalは、デジタルの連続性を維持しながら、ハーネス設計に必要なすべての業務をサポートします。これにより、企業は、グラフィカルな出力とレポートの両方の観点から、ニーズに合わせてツールとプロセスフローをカスタマイズすることができます。

Capitalは、グラフィカルな要素を活かした強力なハーネス設計環境を提供し、設計と検証の自動化を実現します。ハーネス設計エンジニアは、設計意図を効果的に把握・記述し、検証済みで詳細なハーネス設計 (回路図とデータの両方) を作り上げることができます。また、エンジニアは、包括的な設計自動化を促進して一貫性を確保するためのルールと制約を定義することができます。

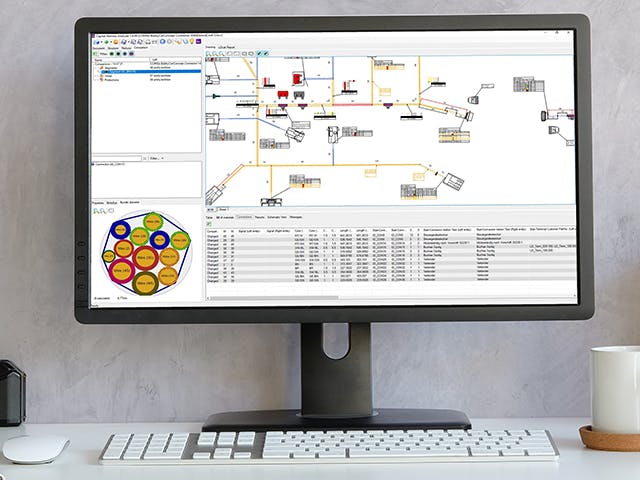

自動化されたハーネス製品エンジニアリング

ハーネス設計では、コスト計算と製造エンジニアリングにより、詳細な関連情報 (ハーネスのコンポーネント情報や下流の消費に必要な材料量など) を追加する必要があります。ハーネス製品エンジニアは、完全かつ正確なハーネス定義を達成するために、設計データを細部まで調整し、関連ドキュメントを抽出して提供することを目指しています。ハーネス・エンジニアリング、検証、レポートの各機能の自動化により、ハーネス・エンジニアは、コスト計算や製造エンジニアリングのタスクを行うための製品データを効率的に準備することができます。

コンポーネント選択ルーチンにより、互換性のある複数のコンポーネントを自動的かつ正確に選択して、コスト計算と製造のための強化されたハーネスデータを作成することができます。自動化された設計比較機能により、異なる製品リビジョン間でグラフィックや仕様変更を識別できるようになります。自動化されたエンジニアリング機能により、完成品の正確な材料量が計算されます。

KBL規格に対応した設計

Capitalには、KBL標準に基づく配線システム設計とワイヤー・ハーネス開発のための主要なアプリケーション・スイートも含まれています。

KBLは、ドイツの自動車産業で使用されているデータ交換標準であり、特にドイツの高級車市場において、各企業の主要開発部門で使用されています。Capitalは、このKBL標準に対応するように構築された製品群を備えており、初期の論理システム概念設計のインポートから、完全なケーブルセットの作成、製造、コスト計算までをサポートします。