製造プロセスの設計、最適化、コスト計算

ハーネスのフォームボード設計

Capitalを使用するフォームボード設計者は、各コンポーネントに関連する工数や時間に対する動的なフィードバックに基づき、人間工学に基づいたレイアウトを作成することができます。

ハーネス製造プロセス計画

Capitalを使用することで、ワイヤー・ハーネス製造プロセス計画やコスト見積もりにベスト・プラクティスを活かすことができます。

ハーネス製造ドキュメントの作成

製造時のミスを最小限に抑えられるかは、製造ドキュメントの品質に左右されます。製造ドキュメントを直接、ハーネスの設計データおよび定義された組み立てプロセスのシーケンスから作成しましょう。

デジタルツインを活用した生産性向上

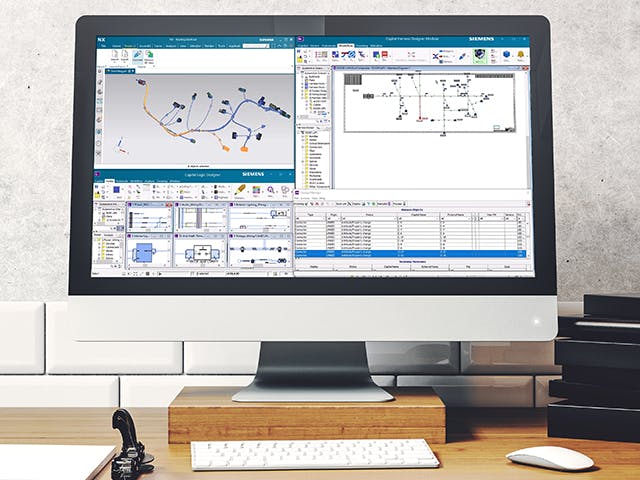

Capitalでデジタルツインを活用して、エンジニアリング、コスト計算、製造のパフォーマンスを変革しましょう。ドキュメント作成のミスを排除すれば、作成にかかるコストを削減し、最終的に利益を拡大することができます。

プロセスの最適化と製造効率の向上

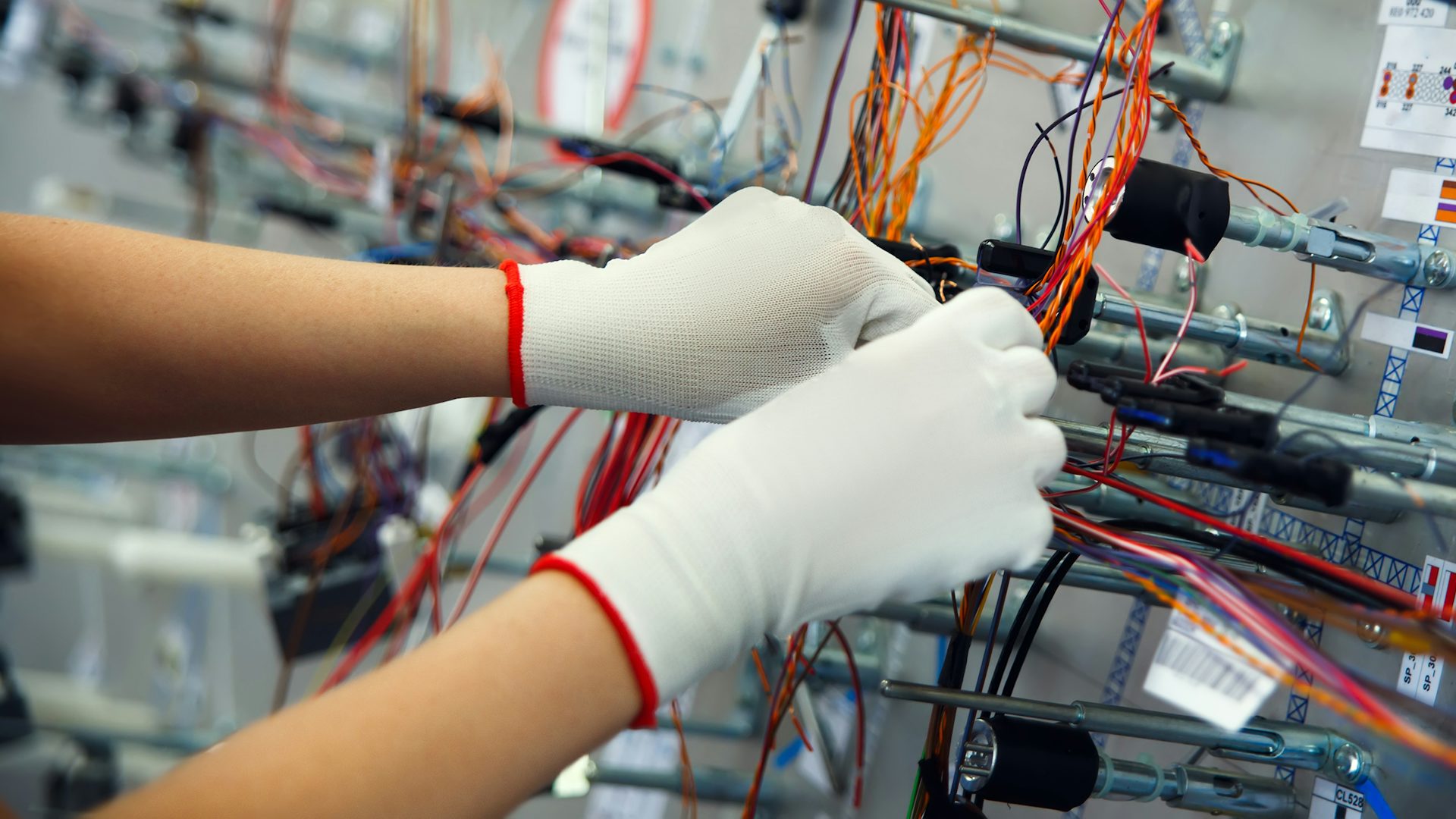

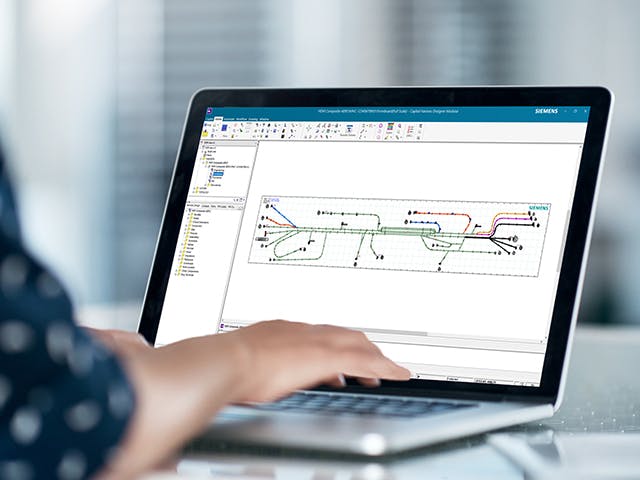

強化された詳細なハーネス設計は、多くの場合、ノンスケールの2Dハーネス図面で文書化されます。この情報をもとに、製造エンジニアは、ハーネス設計データの実物大の表現を作成します。この際、フォームボード図と呼ばれる製造情報が追加されます。

ワイヤー・ハーネス・コンポーネントに加え、製造関連のすべてのオブジェクト (束線フォーク、コネクタ・フィクスチャ、クリップ・ホルダー、テープ位置インジケータなど) がこれらのフォームボード図にグラフィカルに表示され、オペレーターに視覚的な補助が提供されます。Capital内には、フォームボード設計のための強力なグラフィックと設計管理環境が備わっています。これらを使用して、製造エンジニアは、実物大の詳細かつ製造可能なフォームボード図を迅速に作成することができます。

Capitalを使用するフォームボード設計者は、ボード上の特定のゾーンに配置された各コンポーネントに関連する工数や時間に対する動的なフィードバックに基づき、最適化され、人間工学に基づいたレイアウトを作成することができます。また、効率的な生産ラインと工場スペースの使用のために、フォームボードをマージし、管理することができます。

ハーネス製造用ドキュメントの作成

今日の複雑なハーネスにとって、すべての設計および生産施設向けの作業指示書および画像資料を自動的に作成できるかどうかは極めて重要です。

製造時のミスを最小限に抑えられるかは、製造ドキュメントの品質に左右されます。ドキュメントを直接、ハーネスの設計データおよび定義された組み立てプロセスのシーケンスから作成しましょう。

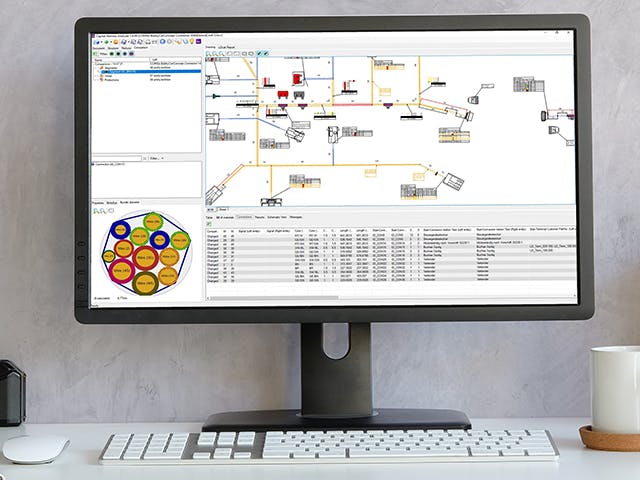

ハーネス製造計画の合理化と最適化

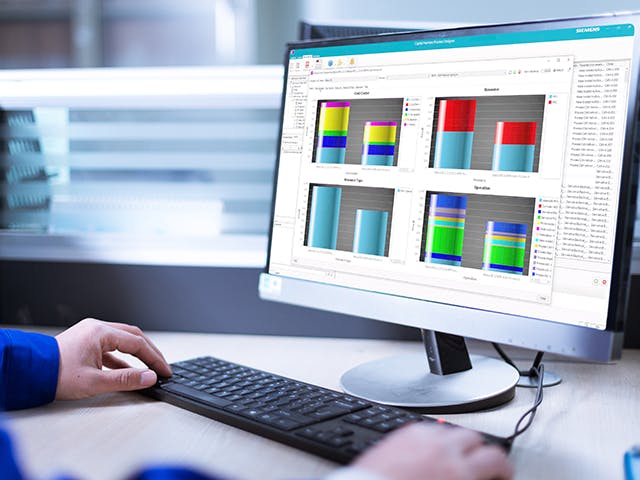

製造プロセス・エンジニアは、目的のハーネスを正しく組み立てるために、シーケンス化されたプロセス・ステップの効率的なパターンを決定するという課題にしばしば直面します。通常は、いくつかのパターンが候補に上がります。最適な選択は、各工場の製造能力によって異なります。Capitalでは、製造するハーネスごとに、効率的な製造スキームを容易に自動作成することができます。これは、ハーネス設計を、事前に把握した製造能力の記述に照らし合わせて分解することで達成されます。この際、ワイヤー・ハーネス・アセンブリ・ロジックを組み込んだ推論エンジンが使用されます。

Capitalを使用することで、ワイヤー・ハーネス製造プロセス計画やコスト見積もりにベスト・プラクティスを活かすことができます。その結果、迅速かつ正確なプロセス計画が可能になり、エンジニアは、最適な製造効率を実現するために、複数の「What-if」シナリオを作成して相互に比較・分析するためにより多くの時間を取ることができます。製造エンジニアは、Capitalで提供される機能を活用することで、効率的な生産ラインを設計し、既存の製造リソースを可能な限り効果的に使用して、テイクレートの変更などの新たな状況に迅速に対応することができます。これにより、製造現場でより良い意思決定を促進し、最終的に収益性を高めるまでの時間を短縮することができます。