MROは、価値の高い物理資産が展開され、使用された後に、その継続的なサービス要件に対応する戦略です。これらの主要資産のOEMおよび所有者/運用者は、MROを採用しています。同じ頭字語は、メンテナンス、修理、運用にも使用され、通常、施設とその機器に適用されるのと同様の戦略を指します。いずれの場合も、メンテナンス、修理、オーバーホールの作業は、 サービスライフサイクル管理 (SLM)ソフトウェアによってサポートされます。

メンテナンス、修理、オーバーホールは、日常的なメンテナンス作業から、必要に応じて修理、資産の近代化、復元、再構築を行う活動、つまりデポレベルのメンテナンスまで、サービス活動の全範囲で構成されています。MROの計画、スケジューリング、実行に対するさまざまなアプローチは、過去半世紀にわたって発展してきました。その多くは、軍用ハードウェアの可用性と任務の即応性を最大化するために軍が開発したメンテナンス戦略として生まれました。

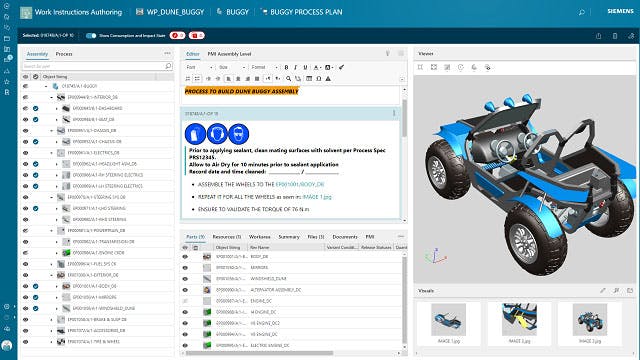

今日のメンテナンス、修理、オーバーホールソフトウェアは、デジタル技術を活用して、幅広い業界のOEMやオーナー/オペレーター、特に長く耐用年数のある高度に設計された製品を扱う企業へのMRO提供の効率と有効性を最適化しています。このような物理資産は、それらを購入する企業や、それらをサービスおよびサポートする企業にとって非常に価値があります。堅牢なメンテナンス、修理、オーバーホール戦略は、可用性と信頼性を最大化することで、これらの資産を最大限に活用することを目的としています。

関連製品: Teamcenterサービスライフサイクル管理