ステレオリソグラフィ(SLA) は、アディティブ・マニュファクチャリング (AM) 用のバット光重合技術で、液体ポリマー樹脂を選択的に紫外線 (UV) にさらすことで3Dオブジェクトを作成します。樹脂の光反応性分子がUV光で照らされると、それらは互いに結合し、光重合と呼ばれるプロセスで固体になります。

ステレオリソグラフィが可能な3Dプリンタ装置を「ステレオリソグラフィ装置」またはSLAと呼ぶ。略語「SLA」は、AM技術と装置の両方を指すために同じ意味で使用されます。熱源を使用して材料を3Dオブジェクトに固化する他のほとんどのAM技術とは異なり、SLAはUV光源のみを使用します。

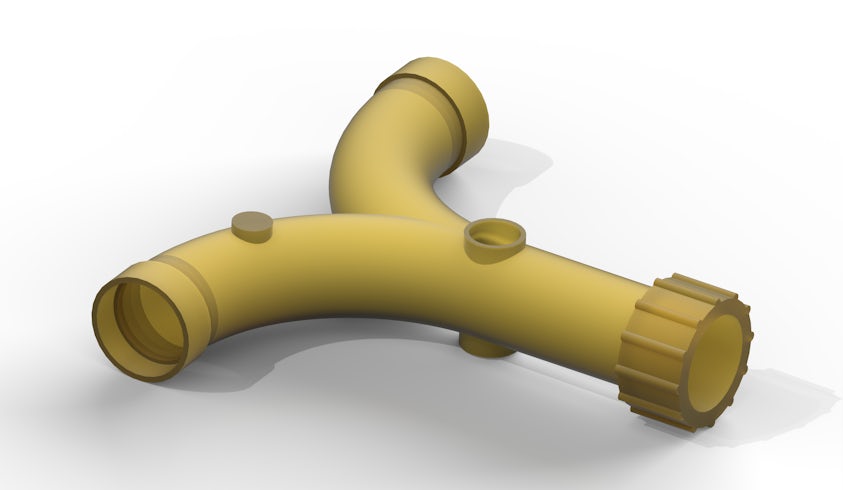

メーカーは通常、比較的迅速で安価なプロトタイピングのためにステレオリソグラフィを使用します。最終的な3Dオブジェクトの正確な特性は、使用するフォトポリマーによって異なります。ただし、ステレオリソグラフィで作成されたほとんどのプロトタイプと部品は、機械加工するのに十分な強度があり、他の製造プロセスのマスターパターンキャストの作成にも使用できます。

関連製品: NX AM固定平面 | NX AM複数軸 | NX AM Build Optimizer