Meeting design needs for custom forklift attachments

CAD with embedded simulation provides fast and accurate job quotes

John Harder & Company

JHC is a leader in designing and manufacturing custom material handling equipment for forklift trucks. The company designs to fit customers’ individual requirements to solve material handling problems with high-quality, special attachments that have durability and long life.

http://www.johnharderco.com- Headquarters:

- Saint Louis, Missouri, United States

- Products:

- Simulation, Solid Edge

- Industry Sector:

- Industrial machinery

Solid Edge Simulation enhances our opportunities and provides us with confidence in our designs.

JHC

John Harder & Company (JHC) designs forklift attachments and machinery to handle materials as important as space shuttle engines and as hazardous as uranium and nerve gas.

Any custom attachment the forklift original equipment manufacturers (OEMs) and dealers need for their material handling customers, JHC can design, validate and build. The company focuses on specialized, custom-built attachments designed to fit its customers’ individual requirements.

More than 20 major forklift truck OEMs use JHC attachments. Thousands of enduser companies buy JHC attachments to handle materials including metals, lumber, paper, appliances, chemicals, food, agricultural goods and many more.

To stay competitive and maintain itself as one of the largest makers of specialty forklift attachments, the company has stayed current with the most productive engineering software tools available. In the early 1990s, JHC moved off its drawing boards to 2D design software. Then, in 1998, the company transitioned to 3D solid modeling, selecting Solid Edge® software from product lifecycle management (PLM) specialist Siemens Digital Industries Software.

“Design tasks that took six hours on a drawing board dropped to about four hours using 2D computer-aided design (CAD), and then to 15 minutes with 3D Solid Edge,” says Mike Peterson, president of the Saint Louis-based company and a former aerospace engineer.

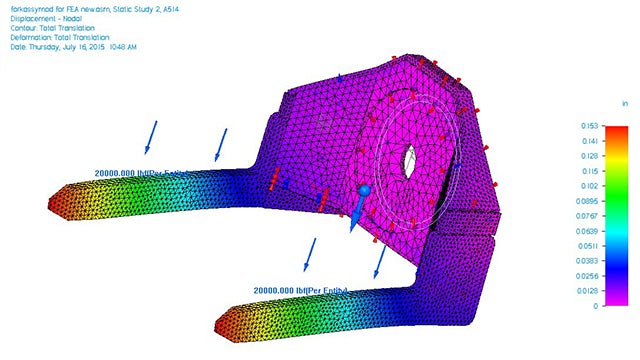

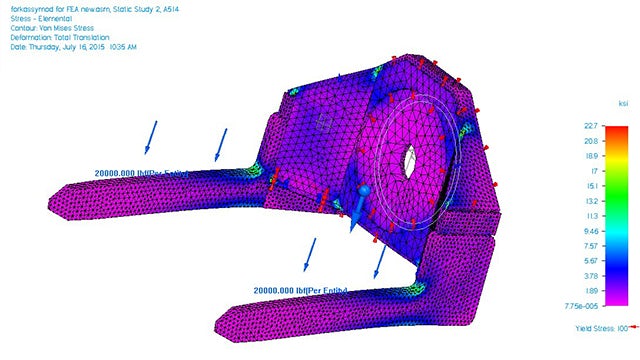

The company recently adopted Solid Edge Simulation to extend its engineering capabilities with integrated stress analysis. “Manual stress analysis is time-consuming to verify alone, so we added Solid Edge Simulation about three years ago,” Peterson says. “We use simulation every week. It gives you an added feeling of security and has helped prevent some designs that were too weak. Solid Edge Simulation used early in the development process provides a good, easy way to visualize and prove a design.”

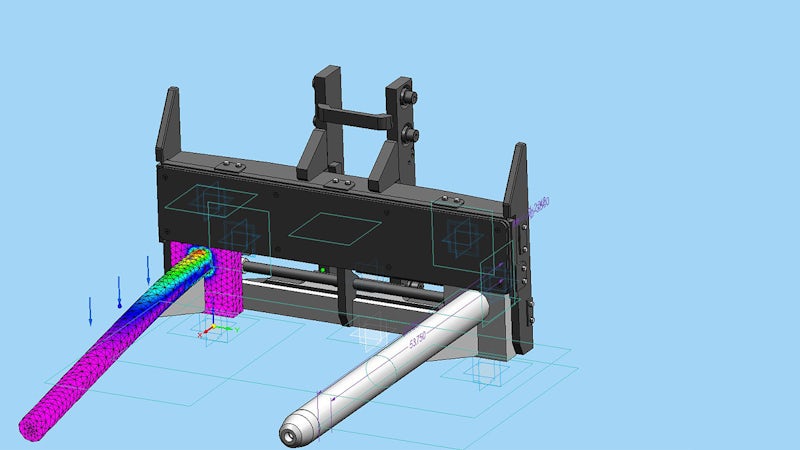

Finite element analysis of a forklift attachment that handles 40,000 pounds of aluminum and then rotates to pour the material out.

Quoting custom jobs

To meet the demand for custom forklift attachments, the company must quickly quote jobs to its customers. Forklifts sold by the OEMs and dealers must be certified to lift-defined weight loads. Because addon attachments reduce the lift-weight rating, JHC must find ways to minimize weight and maintain strength.

To meet customer demand, the company looked into simulation software to check strength, yet keep weight down. Starting with a built-in Solid Edge simulation application for single parts, JHC turned to a third-party finite element analysis (FEA) tool. “We needed to validate assemblies, not just parts,” notes Peterson. When Siemens Digital Industries Software developed a new add-on FEA package for multi-part assemblies ‒ Solid Edge Simulation ‒ the company dropped the third-party tools in order to benefit from a CAD-embedded solution that could be used early in the job-quoting and design processes.

“With CAD-embedded simulation, we can verify manual calculations but don’t have to depend on a third-party package that is not integrated,” says Peterson. “Embedded FEA cuts cost and avoids time-delaying outsourced FEA. We can just do it ourselves.”

Combining sales and engineering

Quick, technically accurate job quotes come with the territory in a custom-product market. “With much of our custom machinery, it’s not practical for early quotations to include fully completed designs,” says Rob Jones, whose job at JHC covers both sales and engineering. “In many cases, they are simply budgetary estimates, but with early simulation our confidence in these estimates is greatly improved. Early use of FEA speeds the process. Hand calculations for loadings on key structural members that could take hours in the past can be done in 20 to 30 minutes now.”

Jones cites an example of a back plate and ram design for a lifting device: “The simulation analysis allowed us to significantly reduce the estimated attachment weight and associated material costs for the initial job quote. We now have an additional engineering tool that helps our customers realize lower costs yet maintain higher net capacity ratings on their forklifts.”

Handling nuclear waste and more

The U.S. Energy Department uses JHC forklift attachments at a major radioactive waste disposal site near Carlsbad, New Mexico. The site is used to dispose of radioactive waste from reactors and associated processes across the United States. The waste is placed into large underground storage vaults and sealed.

Equipment operating in such extreme conditions must be government-approved, in some cases requiring approval by a thirdparty, certified professional engineer (PE). Reports created using Solid Edge can provide documentation on the attachments’ weldments, and the simulation reports also can be submitted to the PE for review.

“Solid Edge Simulation enhances our opportunities and provides us with confidence in our designs,” says Jones.

In many cases, they are simply budgetary estimates, but with early simulation our confidence in these estimates is greatly improved. Early use of FEA speeds the process. Hand calculations for loadings on key structural members that could take hours in the past can be done in 20 to 30 minutes now.

JHC