Integrated product design and data management drives better, faster part production

Funcosa

Fundería Condals (FUNCOSA) is a foundry specializing in the production of medium and large series of melted gray and ductile iron castings. Founded in 1976, the company is internationally known for providing high-quality parts to various industries such as automotive, railway and hydropower.

http://www.condalsgroup.com/- Headquarters:

- Barcelona, Spain

- Products:

- NX, Teamcenter

- Industry Sector:

- Industrial machinery

NX is the only solution that allows us to design and perform a complete machining process, instead of having to design it with one program and then export it to another program.

Funcosa

Enabling strict quality control in the production of metal castings

Fundería Condals (FUNCOSA) provides metal cast parts for the automotive, railway and hydropower industries. Product development at FUNCOSA is ruled by strict quality control, tight tolerances, perfect finishing touches and adherence to deadlines. This requires advanced technology to meet customer demands and honor the company’s commitment to environmental protection, safety and innovation.

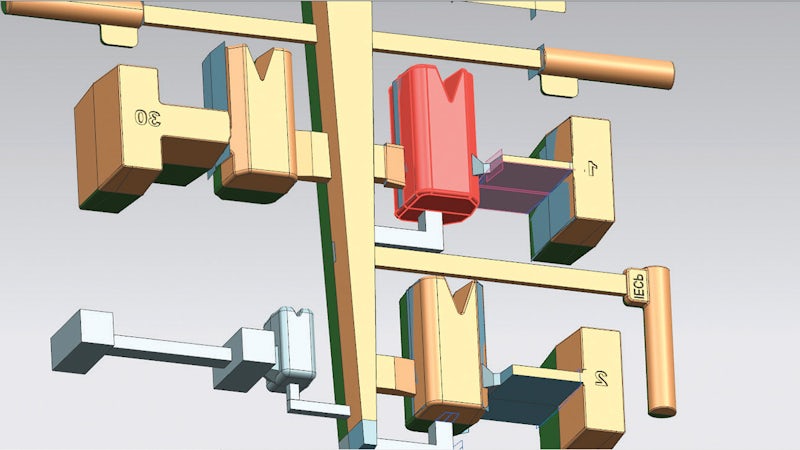

After assessing the computer-aided design and manufacturing (CAD/CAM) software market, FUNCOSA engineers decided to Industrial machinery FUNCOSA Integrated product design and data management drives better, faster part production adopt NX™ software from product lifecycle management (PLM) specialist Siemens Digital Industries Software because it is a fully integrated system. “NX is the only solution that allows us to design and perform a complete machining process, instead of having to design it with one program and then export it to another program,” says FUNCOSA. “NX has become the standard in the design process. NX is our core software, the source of all information. We have other CAD tools, but only use them to support NX.

“We work with crucial parts, so we need systems with multiple capabilities and that can only be provided by market-leading software systems such as NX. That was true fifteen years ago when we decided to incorporate three dimensions in our designs,” says Sallés. “Before that, we worked in two dimensions but found that we needed complete control over the final part design. This could only be achieved by using 3D design. With 2D drawings, there are too many areas subject to misinterpretation.”

Using NX, the technical team can work more accurately and rapidly. “We’re saving a lot of time using NX, and find it useful because it supports multiple design approaches,” says Víctor Fernández, director of process engineering at FUNCOSA. “NX is responsive, enabling you to handle various parts with ease. I have never found a project that could not be addressed using NX.”

The use of NX has become a “must” for many FUNCOSA projects. Sallés explains, “Mold release angles are essential to make both the model and the parts, so we like being able to obtain them automatically. Then you can see if all the faces are correct in relation to the angles.”

The NX feature most highly prized by FUNCOSA engineers is synchronous technology, which speeds up modeling by using simple interactions. Users don’t need to know a model’s design history, so they can intuitively edit design data generated by other systems. “We can make small changes easily and comfortably, such as moving a face, removing a radius or modifying files someone sends you,” says Fernández. This is helpful and takes little time.

The clean and clear interface provided with NX reinforces this capability. “NX allows you to be totally focused on what you have to do, with multiple options to modify the screen to your taste and needs,” says Sallés.

The ease and speed of making modifications is even more valuable when considering the integrated CAD/CAM capabilities of NX. “Any changes you make in CAD are automatically updated in machining,” says Sallés.

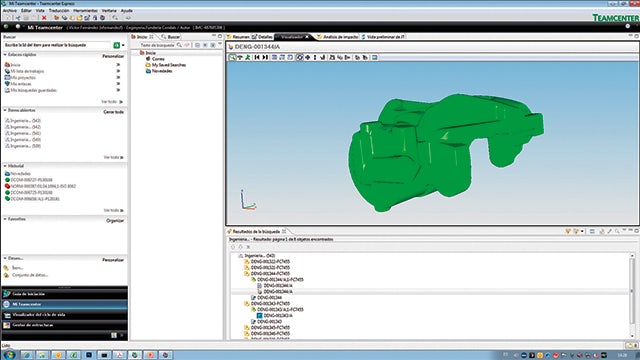

Teamcenter helps centralize project management

FUNCOSA’s satisfaction with NX largely drove the selection of Teamcenter® software, also from Siemens Digital Industries Software, when the company decided to implement more comprehensive PLM capabilities. To help the company earn certifications for quality, a healthy environment and increased worker safety, FUNCOSA needed to replace a paper-based system with an information technology (IT) solution that enables engineers to consult documentation online.

Teamcenter helps centralize project management and facilitates change controls and reviews while managing NX design information and quality documentation. The software has become a key system not only for FUNCOSA’s technical department, but also for its commercial and quality control departments.

“The commercial department uses Teamcenter to find data to fulfill requests for quotations and consult project schedules, says David de la Cruz, director of quality and environment at FUNCOSA. “It’s a basic business tool for the quality department, so users can view technical documentation, such as CAD drawings and models, verification documentation, regulatory issues and customer specifications.”

The combination of NX and Teamcenter allows FUNCOSA to systematize processes for each project, including managing receipts, submitting offers, assessing designs, making design modifications for manufacturing, producing samples, verifying orders, preparing documentation, shipping samples and creating final documentation.

Enabling opportunities for new business

Teamcenter and NX enable a collaborative working environment, helping FUNCOSA achieve excellence in customer service as well as acquire new business. “With the power of 3D design provided by NX, we can take on all kinds of orders,” says Sallés. “We can now get more details and work with complex surfaces that we could not handle in the past. This flexibility allows us to sustain customer satisfaction.”

FUNCOSA is committed to continued collaboration among teams and clients to promote the highest possible quality in all aspects of design, testing and operations. Engineers can import and export any file type with NX and use Teamcenter to facilitate immediate access to any document. “Teamcenter makes it easy to find what you need. Even if you use the wrong search terms, you can find your item due to the multitude of fields and search filters Teamcenter provides,” explains de la Cruz.

The accuracy provided using NX helps reduce errors in design and manufacturing, while the digitization of all documents using Teamcenter avoids duplication and the danger of working with outdated files. “You always know who did what,” says de la Cruz. He points out that these outcomes, coupled with the elimination of paper, enable considerable savings in both direct and indirect costs.

Because of the advantages the technology provides, engineers decided to migrate to the latest versions of both Teamcenter and NX. Using the latest release of NX will enable FUNCOSA to benefit from built-in, fourth-generation design tools. Using Teamcenter, the company plans to deploy new workflows and exercise its full potential in product data management (PDM). The company is also looking at integrating PDM with its enterprise resource planning (ERP) system.

The commercial department uses Teamcenter to find data to fulfill requests for quotations and consult project schedules. It’s a basic business tool for the quality department, so users can view technical documentation such as CAD drawings and models, verification documentation, regulatory issues and customer specifications.

Funcosa

We are saving a lot of time using NX and find it useful because it supports multiple design approaches.

Funcosa

NX is our core software, the source of all information. We have other CAD tools, but only use them to support NX.

Funcosa

NX allows you to be totally focused on what you have to do, with multiple options to modify the screen to your taste and needs.

Funcosa

NX is responsive, enabling you to handle various parts with ease. I have never found a project that could not be addressed using NX.

Funcosa