Realizing faster design of complex pipeline systems for critical applications with Solid Edge

AZ Industrietechnik uses Siemens Digital Industries Software solutions to measurably improve design best practices

AZ Industrietechnik

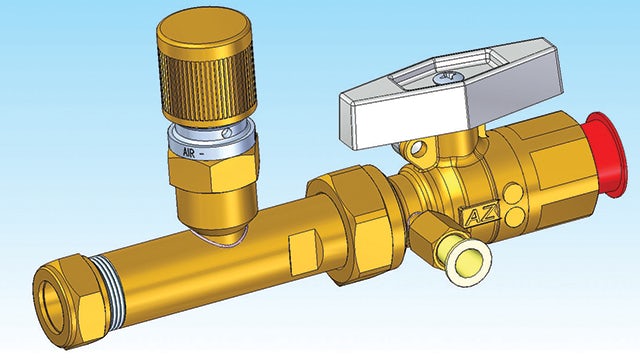

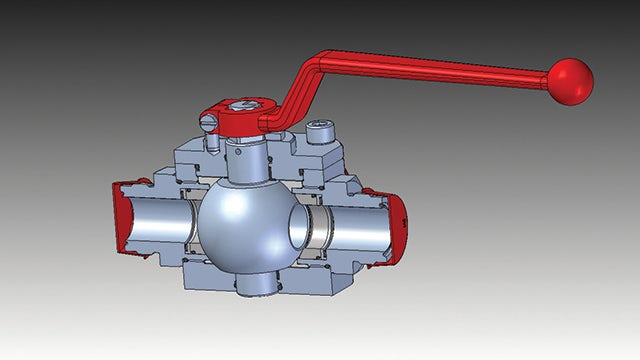

AZ Industrietechnik GmbH offers custom solutions in the area of pipelines, fittings and safety technology for gases and other media. The pipeline systems of the company are used in domestic and heating technology as well as in the medical sector.

http://www.az-industrietechnik.de- Headquarters:

- Olbernhau, Germany

- Products:

- Solid Edge

- Industry Sector:

- Industrial machinery

With Solid Edge, we are able to get a handle on the management of large assemblies and solve demanding design tasks.

AZ Industrietechnik

Customized piping solutions

AZ Industrietechnik GmbH has its headquarters in the middle of the Ore Mountains, in the small town of Olbernhau. The piping technology and fittings specialist grew from a small, regional plant in the 1970s into a leading company for virtually all things having to do with the transmission of liquids and gases. The company is renowned as a reliable provider of customized solutions. Approximately 400 employees work for the AZ Group at seven locations throughout Europe, including the Czech Republic, Great Britain and Italy.

AZ Industrietechnik’s portfolio includes pipelines for drinking water and heating water as well as safety blocks, gas flow monitors and corrugated hoses. Critical fuels and chemicals such as natural gas and explosive gas flow safely thanks to the pipe designs of AZ Industrietechnik. Its solutions are also notable in the medical sector, safely delivering breathable gas to patients.

The company’s comprehensive range of applications, from domestic engineering to machinery to plant engineering, poses significant development/production Industrial machinery AZ Industrietechnik Realizing faster design of complex pipeline systems for critical applications with Solid Edge challenges. The demands on its computeraided design (CAD) system are commensurately high.

A 2D/3D hybrid design solution, Solid Edge provides comprehensive capabilities to deliver design innovation, from sheet metal to routing to visualization.

Solid Edge for specialized design requirements

In its search for an appropriate product development solution, the company turned to PROCIM Systemtechnik GmbH, a solutions partner of product lifecycle management (PLM) specialist Siemens Digital Industries Software. To address AZ Industrietechnik’s comprehensive yet specialized design needs, PROCIM recommended Siemens Digital Industries Software’s Solid Edge® software.

In the fall of 2004, the first of four workstations equipped with Solid Edge was implemented. Employed productively from the beginning, the company now utilizes 14 licenses of Solid Edge. The company is also enjoying the benefits of the Insight™ design data management solution, also from Siemens Digital Industries Software.

The PROCIM/Siemens Digital Industries Software relationship provided a business edge to AZ Industrietechnic. “PROCIM always comes up with a smooth, quick solution for any issues we might have with product development,” says Torsten Zenker, head of Design at AZ Industrietechnik. “Updates are implemented on a regular basis, keeping our CAD technology current. Siemens Digital Industries Software is always developing meaningful upgrades that we are able to put to good use,” notes Zenker. One innovation he particularly raves about is synchronous technology, which represents a step forward in handling data from other systems.

With synchronous technology, users no longer have to choose between constraintdriven or history-free modeling, no longer have to be a programmer to re-use a model, and no longer need to worry about using data from multiple CAD systems.

Realistic visualization of customized products is an important marketing tool at AZ Industrietechnik.

Insight for accelerated revision management

AZ Industrietechnik typically uses the same components over and over again in its design work. Therefore, after the introduction of Solid Edge, it became important to find a CAD data management system in order to also regulate the structured use of identical parts. Here, PROCIM recommended Insight, which utilizes Windows® software, making the system especially familiar and easy to use.

Approximately 11,000 CAD files are now managed with Insight, including 2,500 standard parts. With the assistance of cross-references and search functionality, AZ Industrietechnik’s users can quickly find design and product data created with Solid Edge, which makes knowledge re-use substantially easier and notably reduces design time for similar parts. With Insight, each design iteration is versioned, with all changes registered. In this way, the company’s engineers are confident they are always using the correct data.

Solid Edge, which leverages SharePoint® software, is proving itself at AZ Industrietechnik in daily operations. “Insight helps us achieve our vision of modern data management and completely satisfies our requirements,” says Zenker.

Zenker explains that the ability to quickly and easily identify changes to components and assemblies is essential in the company’s design process. AZ Industrietechnik’s designers accept development tasks from all of the company’s fields of application. Depending on the workload and in the event of vacation or illness, an employee might need to continue the work of another employee. With Insight, the work progresses smoothly because the latest version of a component or assembly is always used. After work on component or assembly models or drawings, the software automatically checks the files, updating associated data as appropriate.

In addition, Zenker says that the designers appreciate the automatic updating of parts lists. To further improve automation and productivity, AZ Industrietechnik is currently working with PROCIM on an interface between the enterprise resource planning (ERP) system and Insight, so that the parts lists are automatically input to the ERP system.

Fast, easy information exchange

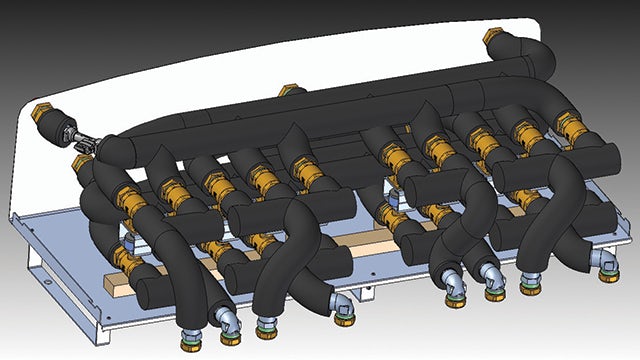

The company’s products consist of a combination of three-dimensional (3D) components designed using Solid Edge and standard and purchased parts provided by suppliers or downloaded from the internet. These 3D assemblies are then used to create required drawings.

Sharing data with customers or suppliers is handled using the STEP data format. Information exchange using this process is thorough and highly reliable. Two-dimensional (2D) drawings in standard formats can be readily produced from the 3D model. Solid Edge provides flexibility in detailing, allowing both standard dimensions as well as custom detailing.

All components are manufactured exclusively in accordance with drawings. Suppliers always receive the drawing of a component first, a CAD model will only be sent as required.

AZ Industrietechnik typically works on solutions that involve complex mechanics, with substantial safety and functionality requirements.

Important capabilities for increased productivity

Zenker points out that Solid Edge offers a wealth of functionality for AZ Industrietechnik’s diverse needs. For example, the company is using an independent module of Solid Edge for automatic sheet metal development, with the software automatically calculating bending radii, bending steps and material consumption depending on the values of the associated database. The simple, secure path from 3D model to developed sheet metal part leads to derived DXF files that are passed directly to the software of the machine tools.

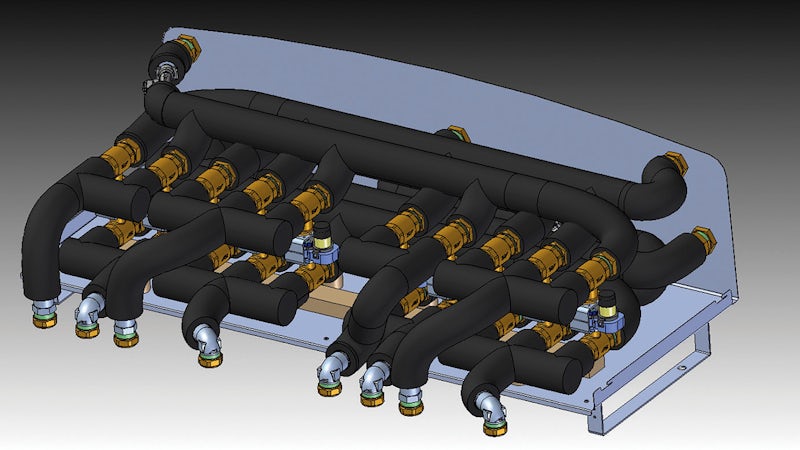

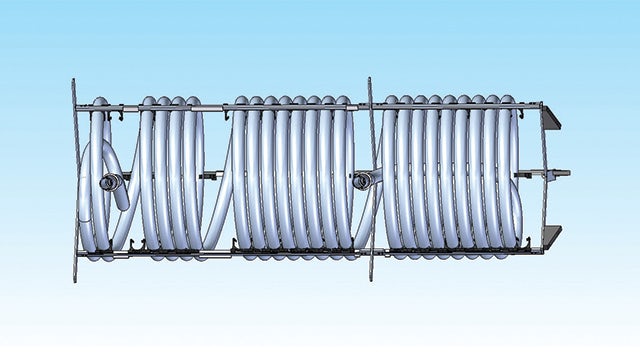

With Solid Edge, the machining of complex assemblies is also fast and convenient. Zenker describes one such example: “This particular geometrically complex heating technology assembly consisted of more than 100 components and sub-assemblies, posing tremendous challenges to the performance of any CAD system.” Zenker says that using Solid Edge, difficult design tasks, such as in the case of the heater technology assembly, are being readily addressed, without waiting periods. Although the company is continually facing market pressures for shorter development times, the use of Solid Edge is enabling ever faster project turnaround. Zenker notes, “With Solid Edge, we are able to get a handle on the management of large assemblies and solve demanding design tasks.”

Visualization is also a key element of the company’s success. At AZ Industrietechnik, the ability to clearly visualize the product design and make a convincing presentation to the customer is essential. Already using the excellent visualization capabilities of Solid Edge, the company plans to implement KeyShot® 3D rendering software, also available with Solid Edge, to put finished products in the optimal light.

Utilizing highlights, selectable textures and custom-designed backgrounds will enable AZ Industrietechnik to give customers a realistic, highly defined impression of the finished product.

Perhaps just as important as design data management, assembly functionality and visualization, is the software’s ease of use. “Solid Edge won us over as a simple and expedient system,” says Zenker. “You can use it to design very different objects practically and in a user-friendly manner.”

Moreover, AZ Industrietechnik’s project engineers say that the greatest advantage of Solid Edge is proving to be its versatility across applications. The company is using the software to develop solar thermal components and assemblies, complex high-pressure hoses and heat exchangers. Zenker concludes, Solid Edge just lets you work effectively.”

The use of Solid Edge, with its broad range of features, helps engineers notably speed up the design of heat exchangers.

Insight helps us to achieve our vision of modern revision management and completely satisfies our requirements.

AZ Industrietechnik