こちらのページは日本語に自動翻訳したものです。

元の英語を表示しますか?

この翻訳は役に立ちましたか?

日常を変える

業界を共に変革し、アイデアをイノベーションに変える。

AIが工場保全をどう変えるか

当社のデジタルツインは 、 データに基づくスマートな意思決定を可能にする、信頼できる唯一の情報源です。現実世界とデジタル世界を組み合わせた真のデジタル・エンタープライズを構築しているのはシーメンスしかありません。

アディティブ・マニュファクチャリング

シーメンスは、あらゆる規模の企業に実用的なアディティブ・マニュファクチャリング技術を提供します。エンドツーエンドのアディティブ・マニュファクチャリング・プロセスを通じて、コスト効果に優れた汎用品を容易に製造します。

人工知能

シーメンスの革新的なAIソリューションは、ビッグデータを活用することで、スマートな意思決定、効率化、品質の向上、市場投入期間の短縮を実現するとともに、新たなビジネスへの扉を拓きます。

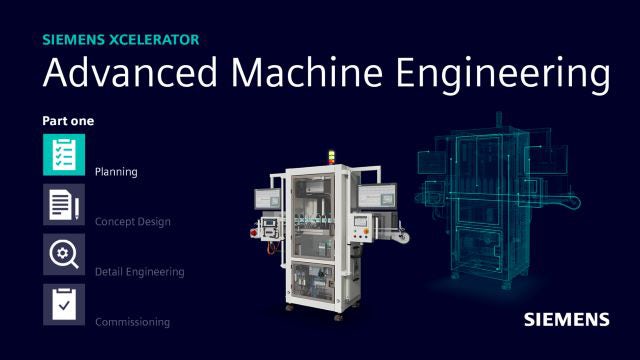

モデルベースのシステム設計

シーメンスの統合モデルベース・システム・デザイン(MBSE)手法は、今日のスマート・システムの構築に必要なすべての領域を統合し、製品イノベーションやビジネスの成功を加速させることに重点を置いています。

デジタル・エンタープライズになるためにはどうすべきか

Surf Lochは、最新デジタル技術を駆使してサーフィン業界に破壊的変化をもたらしています。少数精鋭のエンジニアで構成された同社の設計チームは、Siemens Xceleratorポートフォリオのソフトウェアとサービスを使用して、サーファーがいつでも完璧な波に乗れるサーフボードを開発しました。

感動的なデジタル・トランスフォーメーションの取り組みをぜひご覧ください。

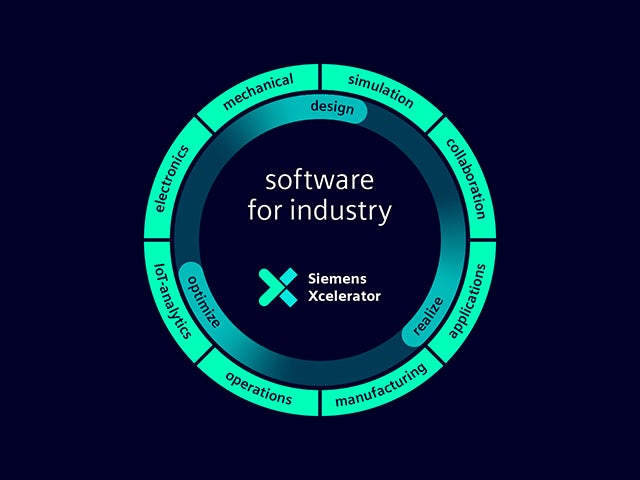

Siemens Xcelerator

日常を変える

Siemens Xceleratorポートフォリオと Siemens Xcelerator as a Serviceの詳細については、シーメンスのブログをご覧ください。