部品製造を加速させる方法とは

部品メーカーは、産業機械の変化に迅速に対応するために、製品ライフサイクル全体を通じて統合型エンジニアリング・ソフトウェアを活用する必要があります。シーメンスが提供するソリューションの強力なデジタル機能により、品質、コスト、エネルギー要件のバランスを取り、新製品導入時の一貫性を高めると同時に、設計を拡張し、市場投入までの時間を短縮することができます。

部品製造プロセスを最適化

知識の共有を強化し、部門間のプロセスを標準化して、新製品開発におけるコラボレーションと連携を強化します。コスト、時間、無駄なリソースを削減しながら、生産量を増やします。

シーメンスのソリューションを使用して、ユーザーが達成したことを紹介します。

プロジェクト実行時間の短縮

NXとTeamcenterを使用することで、生産性の向上、プロジェクト実行時間の20%短縮、エラー報告の削減を実現します。(Burckhardt Compression)

目標コスト計算のプロジェクト

製品コスト管理ソフトウェアを使用して、信頼性の高いコスト比較を作成し、目標コスト計算で、処理されるプロジェクトの量を2倍にすることができます。(Festo)

ドキュメントの重複

ドキュメントの重複を排除できます。受注してからERPシステムに完全なBOMを提供するまで、製品開発を管理します。(Gate)

エンジニアリング・プロセスを改善

迅速な製品設計、開発、納品のための最も重要なソリューションを組み合わせた統合システムを活用します。

部品製造のNPIの3つの主要分野を探索します。シーメンスのソリューションは、各分野のニーズを満たすように開発されています。

ダイナミックで合理化された環境で最適な設計を促進するための新しいアプローチを発見します。新製品の設計を視覚化、共有、検証するための 3Dデジタルツインを迅速に開発します。トレーサビリティとコンプライアンスを確保しながら、製品開発を加速します。

- 変化する顧客要件に対して内部要件のバランスを取り、検証する

- デジタルツインを使用して市場投入期間を短縮し、チーム全体の可視性を向上

- 製品のばらつきがコストと持続可能性に与える影響を可視化

製品開発ライフサイクル

完全に統合されたソフトウェア・ツール・スイートを活用して、すべてのプロジェクト要件、構成、変更管理を1か所に集約します。この統合ビューを使用して、要件に合わせて調整し、カスタマイズされた製品バリアントを作成して材料コストを制御します。

- プロセスを標準化、自動化して納期を短縮

- 貴重なデータを収集して再利用し、時間の短縮、コストの削減、品質の向上を実現

- コストを管理し、収益性を高めるカスタマイズされた製品バリエーションを作成

製造コストと効率

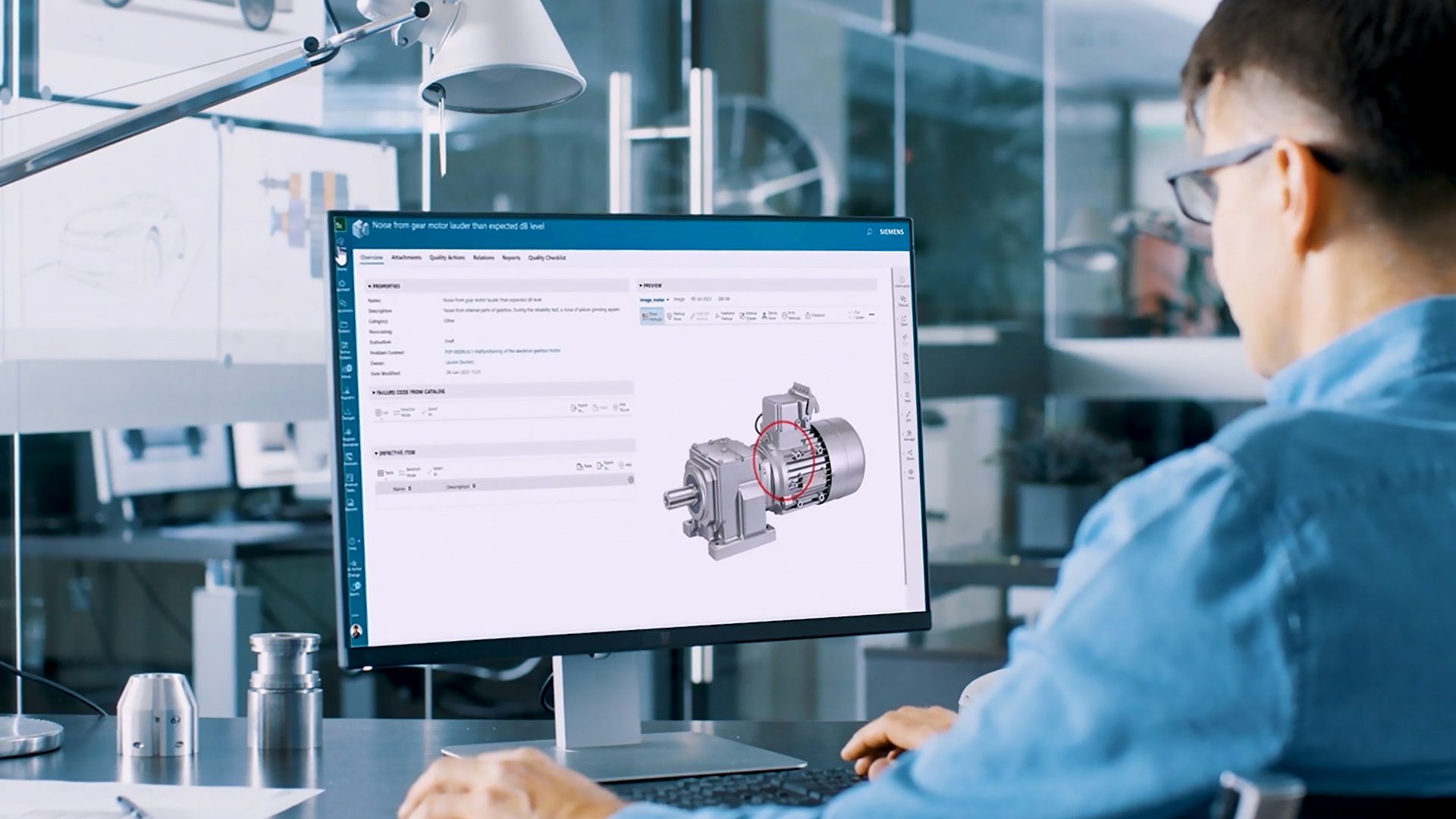

品質管理システム (QMS) と製品ライフサイクル管理 (PLM) プロセスを統合して、エンドツーエンドのソリューションを作成します。モジュール設計ツールを使用して、一貫性のある製品を開発、構成、拡張し、製品の標準化を通じて新しいレベルの品質を生み出します。

- 製品ライフサイクルのあらゆる段階で品質目標を達成

- ドラッグアンドドロップ・ツールで一貫性のある高品質な製品を開発

- 製品の信頼性を高め、リピートビジネスを生み出す

シーメンスとともに部品製造を加速させましょう

シーメンスのソリューションによって、ユーザーが部品製造プロセスをどのように変革しているかをご覧ください。

早期から設計精度を確保

プロセスの早い段階で正しい設計決定を下し、複雑な設計をより迅速に完了します。(Werner Weitner)

オペレーションを効率化

製品開発プロセスをグローバルに管理し、オペレーション効率を大幅に向上させます。(Bonfiglioli)

最適化されたCAD形状を作成

機械部品の最適化されたCAD形状を実現します。(Studio Tecnico Zocca)

Marquardt Group

Marquardt Group enhances product costing processes using Teamcenter

会社:Marquardt Group

業界:自動車 / 輸送機器, Electronics, Semiconductor devices

開催場所:Rietheim-Weilheim, Germany

シーメンスデジタルインダストリーズソフトウェア:Teamcenter

Teamcenterの製品コスト計算ソリューションは、透明性とコスト情報の精度を高め、すべての部門とプロジェクト・チームから高い評価を得ています。

新製品導入を加速させるソリューション

包括的なデジタルツイン

統合された製品データ

品質と製造の統合

製品コスト管理

要件管理と検証管理

性能エンジニアリング

よくある質問 (FAQ)

新製品導入プロセス (NPI) とは何ですか?

NPIは、製品アイデアをすべて再現可能な完全な最終製品に変換するための構造化されたプロセスです。NPI市場の需要に応える製品バリエーションを展開するためには、モジュール式の構成可能な設計アプローチをサポートする統合型のNPプロセスが必要です。

製造効率を上げるにはどうすればよいですか?

デジタライゼーションは、部品製造のプロセスを改善するために不可欠です。クラウドベースのツールを使用すると、ビジネスの効率、速度、収益を向上できます。デジタルツインは、設計、製品計画、カタログ作成、製造などの各領域すべての製品データを表示する単一のビューを提供します。これによって、製品開発の目標に合わせて、プロセスを標準化して一貫性を高め、品質保証を向上させることができます。各領域を強化して、変化する顧客の要件に対して社内ニーズのバランスを取り、検証し、迅速なプランニング、スケジューリング、実行、市場への提供につなげます。

製造業におけるコスト削減のアイデアにはどのようなものがありますか?

シーメンスのデジタル・ソリューションを活用することで、部品製造における 製品の収益性を管理し、ライフサイクルの早い段階でコストを削減できます。クラウドを利用してサプライチェーン・ベンダーや流通ネットワーク・パートナーと迅速につながり、外部コスト支出とを把握して制御します。デジタルツインを使用して、エネルギー使用量を削減し、コスト効率が高く持続可能な材料を導入します。

製造コストを削減するにはどうすればいいですか?

シーメンスのデジタル・ソリューションを使用して、製造コストを削減し、ビジネスの利益率を高めることができます。シーメンスのソリューションによって、コスト管理と設計、品質、製造、バリエーション管理を、堅牢で安全なクラウド・インフラストラクチャに統合し、要件との一致を強化できます。コスト・エンジニアは早い段階からコラボレーションできるため、コミュニケーションの行き違いが減って、製品開発は、利益率の高い持続可能な選択肢に集中できるようになります。製品の信頼性を高め、再受注を確保し、コードの再利用により、迅速なカスタマイズと拡張を実現し、これまで以上に利益率の高い、高額な手数料の依頼に応えられるようになります。

製造品質を向上させるにはどうすればよいですか?

機器や部品メーカーは品質を第一に考えて、製品ライフサイクル管理 (PLM) と統合された品質管理システム (QMS) を使用しています。QMSは、それ自体で製品の欠陥や不適合を追跡すると同時に、生産が規制、保証基準、品質管理プロトコルに準拠していることを確認するシステムです。品質システムと新製品導入開発を統合することで、メーカーはより高品質の部品を生産できます。