高精度で高品質、カスタマイズ、サステナブルな部品を予定どおりに大規模に生産し、全体的な生産性と収益性を向上させるにはどうすればよいでしょうか?

ツーリングと部品製造のための統合ソフトウェアソリューションを実装します。実績のある強力なソフトウェアツールとソリューションを使用して、デジタルマシンショップの設計、生産、運用を自動化し、シームレスに接続します。

短納期、ほぼ完璧な精度、革新的な製品に対する顧客の要求には、次世代の俊敏な部品製造プロセスが必要です。しかし、多くのメーカーは、専門的で分断されたソリューションと部分的な自動化に基づく従来の(そしてしばしば非効率的な)プロセスに依拠しています。

顧客の期待に応えながら、必要な生産性と利益率を実現するには、チームをシームレスに接続しながら、プロセスを自動化する必要があります。このエンドツーエンドのプロセスにより、最適な部品製造プロセスを定義し、製造現場での高効率な生産を実現します。

Lifecycle Insightsによると、次のようになります。

エンジニアの27%が、生産の遅れの主な原因は、異なるソフトウェア間のデータ転送と、対応が困難な設計変更であると述べています。

21%の企業が、ツールパスを確実に生成するためにCAMソフトウェアに完全に頼ることはできないと報告しています。日常的に、CAMソフトウェアアプリケーションでツールパスを手動で変更しています。

多くのメーカーは依然として分断されたワークフローで作業しており、50%以上がスタンドアロンのCAD/CAMシステムに依存しています。このアプローチは時間がかかり、納品までの時間が遅れる可能性があります。

高精度で高品質、カスタマイズ、サステナブルな部品を予定どおりに大規模に生産し、全体的な生産性と収益性を向上させるにはどうすればよいでしょうか?

ツーリングと部品製造のための統合ソフトウェアソリューションを実装します。実績のある強力なソフトウェアツールとソリューションを使用して、デジタルマシンショップの設計、生産、運用を自動化し、シームレスに接続します。

デジタル部品製造のためのシームレスに統合されたソリューションにより、高精度の部品をより迅速に提供できます。CNCマシン、ロボット、3Dプリンター、品質検査装置をプログラムします。デジタルスレッドを使用して人、システム、機械をつなぐことで、効果的なコラボレーションを実現します。

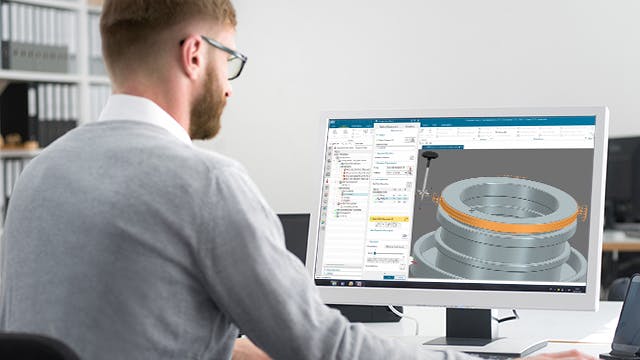

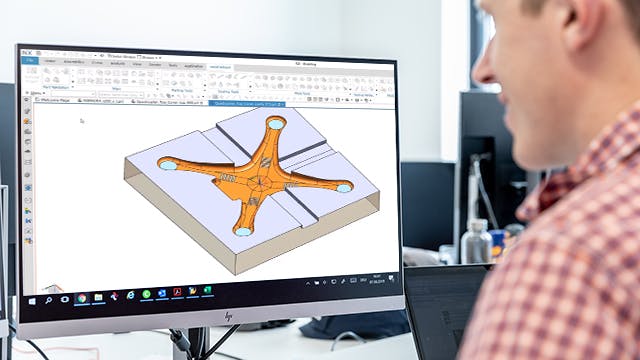

初期コンセプト設計から完成部品まで、完全な統合デジタル環境を提供する統合CAD/CAMソリューションにより、部品生産を改善します。この統合システムにより、アプリケーション間でのシームレスな3Dモデルの移行が保証され、生産ワークフローが最適化されます。

CNC(コンピューター数値制御)マシンとロボットのプログラミングを自動化し、高度なツールパステクノロジーと統合されたGコード駆動型シミュレーションを使用して高精度部品を製造します。

革新的な製品の設計、シミュレーション、準備、3Dプリントを行います。材料の無駄を減らして、強化された形状で複雑で複雑な部品を作成します。

三次元測定機(CMM)の検査プログラミング、実行、測定データ分析をつなぐクローズドループソリューションを使用して、部品の品質を検証します。

プロセスベースの設計アプリケーションを使用して、関連性のある金型、プログレッシブ、スタンピングダイ、取付具の設計を自動化します。

製造データの単一ソースを使用してエンジニアリングと製造現場をシームレスに接続し、高品質の部品をより効率的に生産

NX CAMを今すぐ試して、高性能な部品製造を体験してください。

1つのCAMシステムを使用してあらゆるジョブをプログラムします。高度な技術を使用して機械を加工し、NCプログラミングを自動化し、機械の稼働時間を増やします。

NX CAMのエクスペリエンスは、強力なソフトウェアにとどまりません。NX CAMが一貫して高い評価を得ている理由を、ご自身でお確かめください。

NXでは、設計やCAMプログラミングからアディティブ・マニュファクチャリングや品質保証まで、製造プロセス全体を1つのソフトウェアでマッピングすることができます。最初のアイデアからすぐに使える部品まで、10日以内に新しい部品を作ることができました。以前のプロセスでは、これには数週間かかっていました。

部品製造の旅を簡単に始めましょう。カスタマイズされたサポートと柔軟なサービスが、お客様をガイドします。

NX CAMを当社の幅広いデジタル・マニュファクチャリング・ソリューションにシームレスに統合することで、一歩先を行くことができます。3Dプリンティング、ロボティクス、生産ライン設計などのためのさまざまなソフトウェアで、進化する業界のニーズに対応します。

Siemens Xcelerator Academy を使ってみましょう。NX CAMを使いこなして、ツーリングと部品製造プロセスの最適化の第一人者になりましょう。

他の製造専門家とつながり、新しい技術を学び、アイデアを共有し、ツーリングと部品製造の専門知識を継続的に向上させましょう。

コンピューター支援製造ソフトウェアは、NCプログラマーがCNC工作機械の詳細な指示(Gコード)を作成するために使用する強力なツールです。これらの指示は、さまざまな部品を製造する機械をガイドして、目的の精度と品質を実現します。さまざまな業界のメーカーが、CAMソフトウェアを利用して、さまざまな複雑さのコンポーネントの生産をデジタル化しています。製造プロセスを自動化および合理化し、機械加工作業の 全体的な生産性を向上させ ます。

部品製造およびツーリングソフトウェアソリューションは、デジタルマシンショップの設計、生産、オペレーションを自動化し、シームレスに接続するのに役立ちます。計画から生産までのシームレスなデータフローを、 完全に統合された包括的なツールセットで実現します。CAD、CAM、ロボティクス、CNC(コンピュータ数値制御)加工、CMM(三次元測定機)検査、 3Dプリント。

ツーリングおよび部品製造ソフトウェアソリューションにより、エンジニアは高精度で高品質なカスタマイズされたコンポーネントをより迅速かつ大規模に作成できます。実際、統合ソリューションを使用すると、エンジニアは 最大4倍の速さで部品を作成し 、リードタイムを半分に短縮しながら、CNCプログラミングを91%高速化できます。デジタルマシンショップは、3D設計からCNC機械加工、ロボット工学、品質管理、完成部品まで、シームレスでデータ駆動型の生産を可能にします。これにより、企業はより効率的で競争力があり、収益性が高く、持続可能なビジネスを運営することができます。

CAMソフトウェアを選択する際には、以下のガイドラインを参考にして、お客様のビジネスに最適なソフトウェアを見つけてください。

ビデオ |設計から金型まで: クワッドコプターの構築

オンデマンドウェビナー |部品製造を加速する高ダイナミック旋削加工

ビデオ |シーメンスのNXは、セメントレス人工膝関節置換術のパイオニアを可能にします