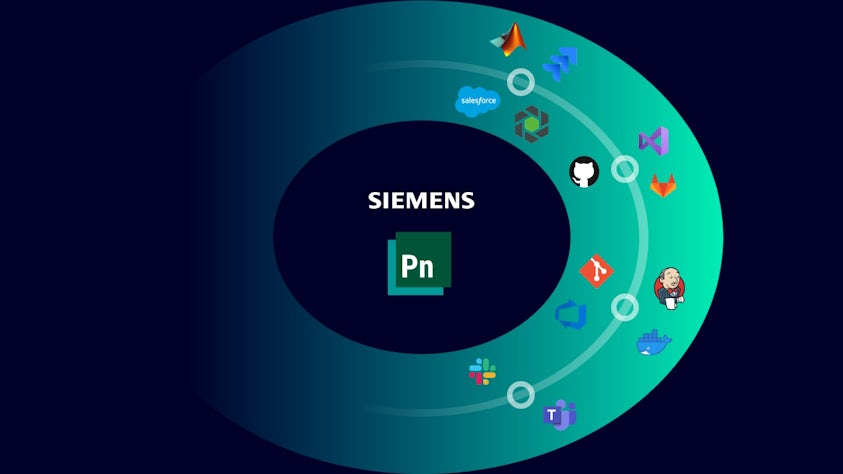

Requirements management

Effectively gather, author, approve and manage requirements for complex systems across entire project lifecycles.

An exclusive innovation, Polarion LiveDoc—online structured specification documents—are fast becoming the way companies of all sizes gather, author, approve, validate and manage requirements.