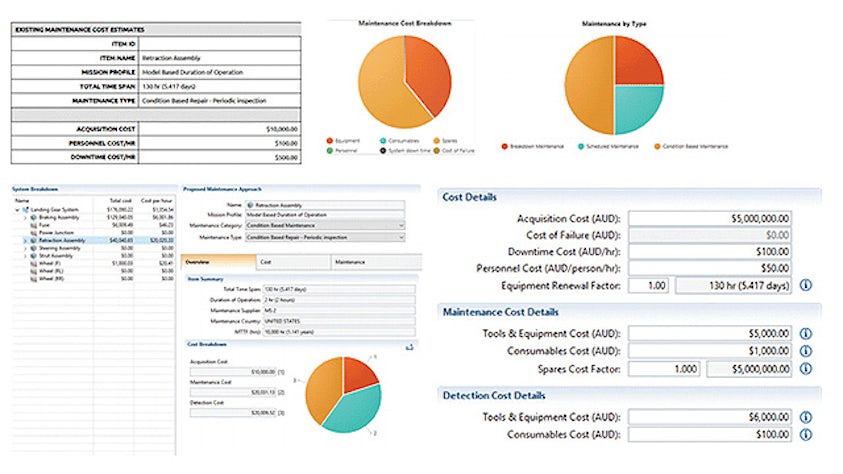

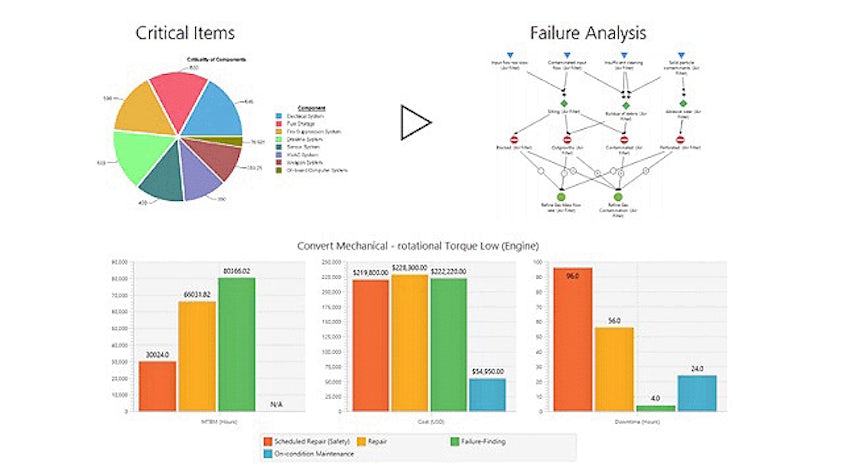

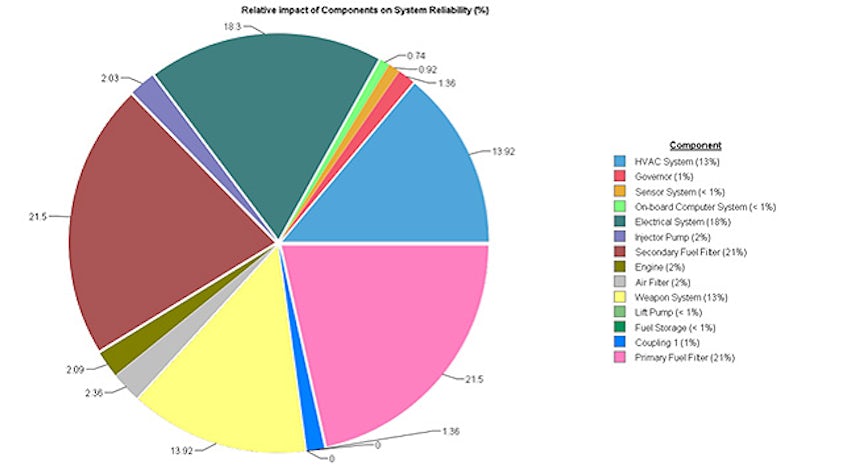

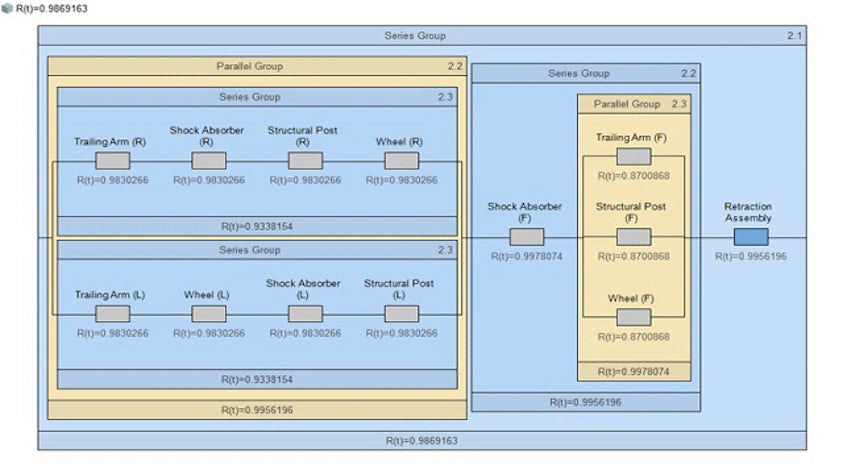

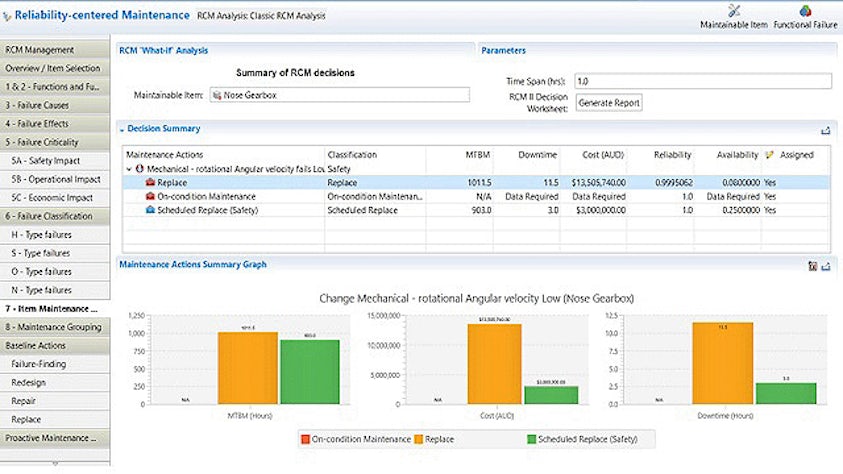

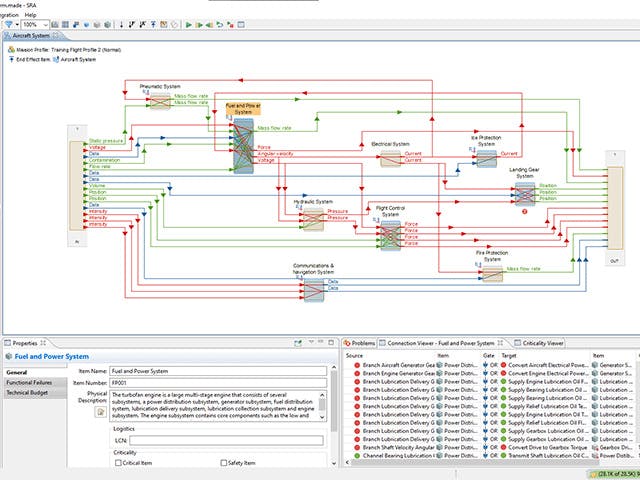

Abilita l’esecuzione di analisi e studi commerciali dei costi di mantenimento in base alla configurazione di progettazione, al profilo di missione associato, all'ambiente operativo e all'approccio di manutenzione. Stabilisci una stima accurata dei costi per il sistema, i sottosistemi e gli assiemi chiave di un asset e quindi utilizzala per confrontare i costi di manutenzione durante l’intero ciclo di vita con soluzioni di manutenzione alternative.