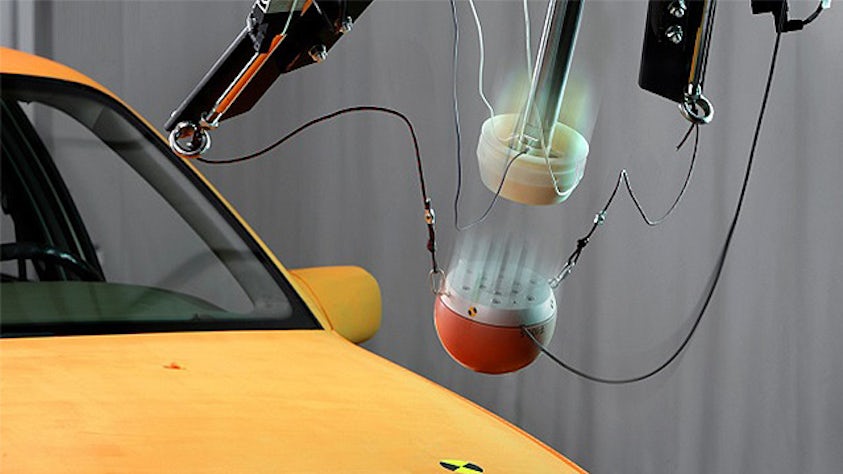

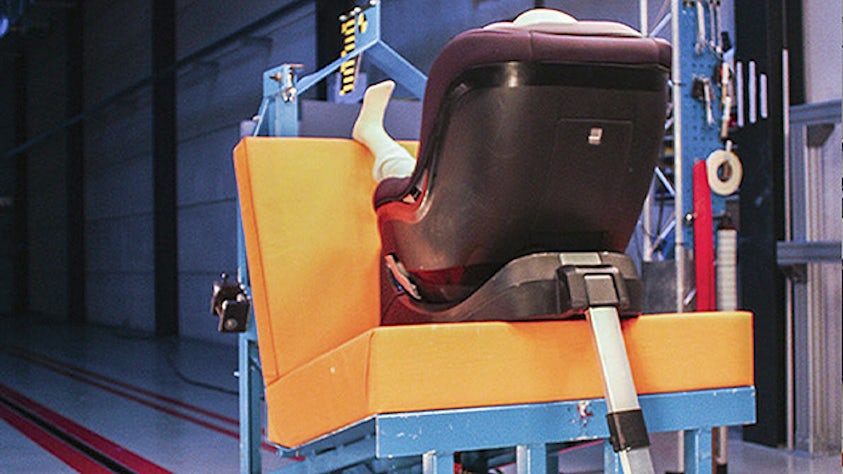

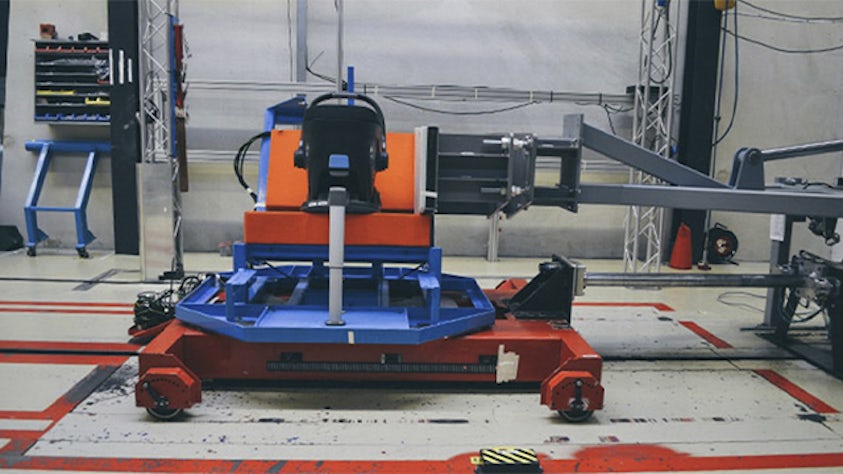

I nostri servizi di test di sicurezza a Helmond, nei Paesi Bassi, sono accreditati EN ISO/IEC 17025 (registrazione n. L547) e designati per la certificazione dal centro di prova RDW (E4) e KBA (E1) offre un'ampia gamma di test su componenti e sistemi di sicurezza: dai caschi ai sistemi di ritenuta completi. Insieme ai test di sviluppo, offriamo la verifica finale e indipendente della conformità del prodotto rispetto agli standard mondiali.

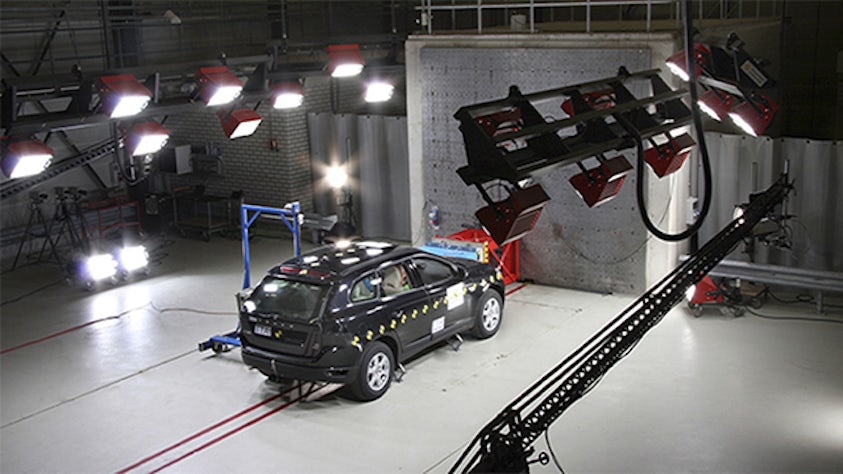

Oltre a testare componenti di sicurezza specifici, verifichiamo la sicurezza complessiva dei veicoli. Grazie a più di 30 anni di esperienza, offriamo software di simulazione e conoscenze e strumenti complementari per lo sviluppo, la progettazione, il collaudo e la validazione di vari sistemi di sicurezza passivi e attivi. Le nostre strutture di test sono completamente attrezzate per eseguire un'ampia gamma di test per applicazioni automobilistiche, sia all'interno che all'esterno.