Chiamata anche gestione delle risorse di servizio, la gestione delle risorse fisiche viene spesso applicata ad apparecchiature, macchinari, dispositivi, veicoli e altre risorse complesse con cicli di vita del prodotto relativamente lunghi.

La gestione delle risorse fisiche viene in genere eseguita da un software di gestione delle risorse, che fa parte di un sistema di gestione del ciclo di vita dei servizi (SLM ). Il software di gestione delle risorse collega le attività di assistenza con la cronologia di un asset, lo stato operativo, i tempi di inattività non pianificati, i requisiti di manutenzione regolamentati, la configurazione corrente e altro ancora.

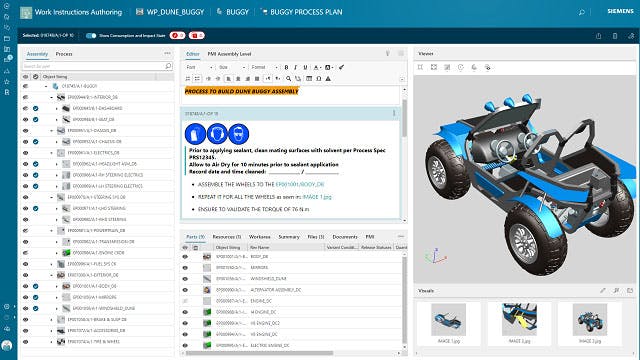

Il software di gestione delle risorse fisiche raccoglie e mantiene aggiornate le informazioni specifiche delle risorse durante l'esecuzione dei servizi. Fornisce inoltre ai tecnici dell'assistenza informazioni aggiornate sulla configurazione delle risorse, materiali di assistenza come parti e kit e la documentazione tecnica di cui i tecnici hanno bisogno per eseguire un servizio rapido e corretto al primo tentativo. Il software fornisce inoltre un ecosistema aperto, visibile e accessibile agli OEM, ai clienti e alle terze parti coinvolte nella fornitura di un servizio efficace per gli asset gestiti.

Un gemello digitale completo e fruibile, una rappresentazione virtuale contenente la struttura fisica aggiornata dell'asset gestito, è fondamentale per la gestione degli asset fisici. Questo gemello digitale comprende tutti i componenti meccanici, elettrici/elettronici, software e i relativi documenti associati di ogni asset, nonché lo stato e la cronologia del loro utilizzo operativo.

Prodotti correlati: Teamcenter Service Lifecycle Management