DFS è una strategia del ciclo di vita del prodotto che affronta gli attributi di manutenibilità di un prodotto. Questi attributi, come l'affidabilità, la configurazione e l'ergonomia, hanno un impatto diretto sul costo e sull'efficacia della manutenzione del prodotto. La progettazione per il servizio è un aspetto critico della gestione del ciclo di vita del servizio (SLM), parte integrante della gestione del ciclo di vita del prodotto (PLM).

Gli specialisti dell'ingegneria dell'assistenza si sono resi conto che molti degli attributi del prodotto che influenzano, assistono o ostacolano il servizio sono progettati nel prodotto. Ciò significa che l'impatto di questi attributi sull'esecuzione del servizio continua per tutto il ciclo di vita del prodotto. Lo scopo di una progettazione per il servizio è quello di includere deliberatamente attributi nella progettazione che influiscono positivamente sull'esecuzione del servizio.

La progettazione del prodotto per il servizio offre un quadro strutturato per aiutare i produttori a determinare il giusto equilibrio tra affidabilità e manutenibilità.

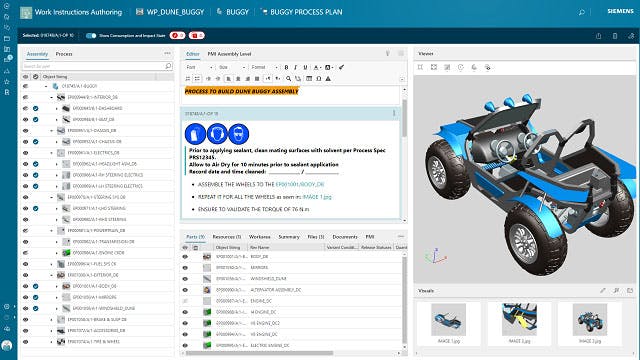

Prodotti correlati: Teamcenter Service Lifecycle Management