Tecnologie e processi di produzione additiva

La produzione additiva può essere realizzata utilizzando varie tecniche come il Binder Jetting e la produzione di oggetti laminati, ma le tecnologie seguenti sono le più frequentemente utilizzate per la stampa 3D.

Estrusione di materiale (FDM, FFF)

Questo processo utilizza una bobina di materiale (solitamente a base di polimeri) e una testa di deposizione riscaldata. La testa fonde il filamento per estrudere il materiale in un lungo flusso. FDM è la tecnologia utilizzata nella maggior parte delle stampanti desktop a basso costo a causa dell'accessibilità economica delle parti e dei materiali prontamente disponibili sotto forma di filamento/bobina. Il software per FDM multiasse è stato introdotto per la prima volta da Siemens e dai suoi partner nelle nostre soluzioni NX. La nostra soluzione è stata testata e migliorata nel corso di diverse generazioni ed è la piattaforma più robusta per questo tipo di operazioni.

Stereolitografia (SLA)

La stereolitografia è uno dei più antichi processi di produzione additiva (AM) e utilizza resine liquide per creare oggetti 3D. Nella maggior parte dei casi, le resine vengono polimerizzate utilizzando la luce ultravioletta. Le stampanti SLA sono in qualche modo diverse dalle altre tecnologie perché la parte viene stampata nella direzione –Z. Ciò significa che una volta solidificato, ogni strato della parte stampata viene spinto verso il basso nella resina piuttosto che essere costruito verso l'alto, come con la maggior parte degli altri processi.

Fusione a letto di polvere (DMLS, SLS, EBM)

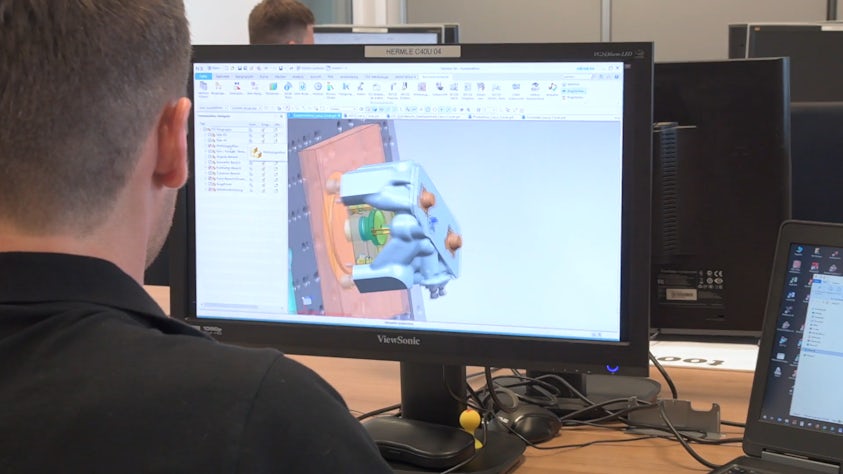

Powder Bed Fusion è un termine che descrive molti processi additivi, tra cui la produzione additiva in metallo. Tutti coinvolgono un letto di materiale in polvere che viene fuso strato per strato in modo planare. Questo viene fatto con più tipi di materiali, sia plastica che metallo. Una moltitudine di tecnologie viene utilizzata per fondere il materiale in polvere. La natura integrata di Siemens NX consente di eseguire le attività necessarie, come il nesting 3D dei pezzi nel vassoio di costruzione o la costruzione di strutture di supporto per la stampa PBF senza traduzioni dei dati o l'utilizzo di pacchetti software esterni. Il vantaggio è che, man mano che la geometria della parte cambia attraverso le revisioni, le operazioni a valle vengono aggiornate automaticamente con un'interazione minima da parte dell'utente, risparmiando grandi quantità di tempo di progettazione e configurazione.

Binder Jetting

Il Binder Jetting è una categoria di tecniche di produzione additiva (AM) che utilizzano testine di stampa a getto d'inchiostro per depositare selettivamente un agente legante liquido su materiale in polvere per formare oggetti 3D solidi. Poiché le molecole di polvere sono legate insieme da una reazione chimica adesiva invece di fondersi o sinterizzarsi dall'energia termica applicata, le tecniche di getto di legante sono distinte dalle tecniche di fusione a letto di polvere.

Getto di materiale

Il getto di materiale è un processo di produzione additiva (AM) in cui le goccioline di resina liquida vengono depositate selettivamente tramite testine di stampa a getto d'inchiostro e solidificate mediante esposizione alla luce ultravioletta (UV) per costruire un oggetto 3D solido. Il getto di materiale è considerato uno dei metodi più precisi di produzione additiva. In grado di stampare in strati di spessore inferiore a 20 micron, il getto di materiale è noto per la creazione di progetti CAD con dettagli precisi, elevata precisione e superfici lisce.