La SLS è una tecnica di fusione a letto di polvere per la produzione additiva (AM). Crea oggetti 3D utilizzando un laser per riscaldare selettivamente le particelle in polvere in modo che si fondano e diventino una struttura solida.

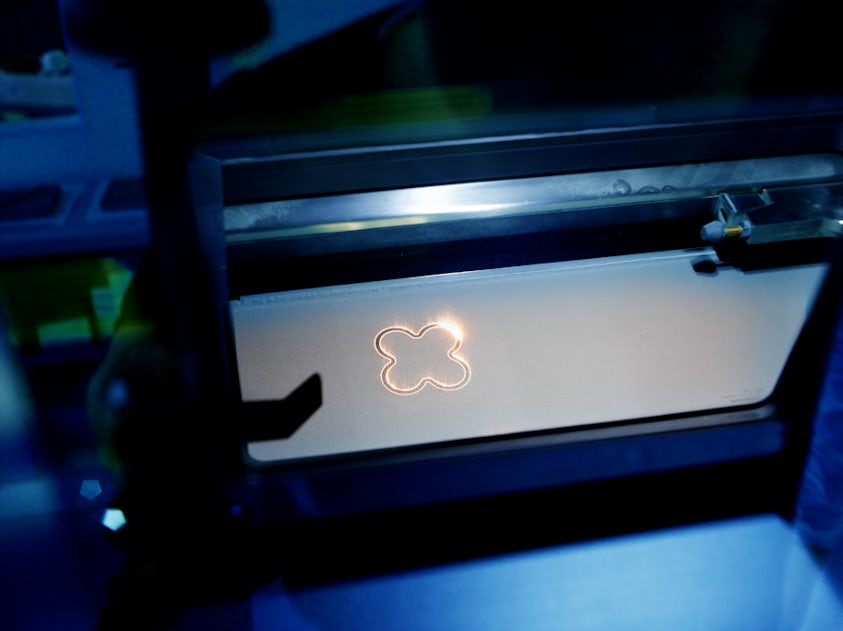

Durante il processo di sinterizzazione, il materiale viene riscaldato quel tanto che basta per avviare la diffusione atomica tra le particelle, facendole legare senza fondersi effettivamente. Una macchina SLS utilizza un laser pulsato per sinterizzare le particelle in polvere con una precisione sufficiente per stampare in 3D parti con geometrie altamente complesse in plastica, metallo, ceramica e vetro.

Poiché è in grado di creare facilmente forme complesse direttamente dai dati CAD ed è compatibile con un'ampia gamma di materiali, la sinterizzazione laser selettiva è una tecnica estremamente versatile per la produzione di prototipi e parti per uso finale.

Prodotti correlati: Piano fisso NX AM | NX AM multiasse | NX AM Build Optimizer (Ottimizzatore di build NX AM)