Precision software helps enable precision engineering

Simcenter Amesim helps Parker Hannifin achieve quality in high precision system engineering...

Parker Hannifin

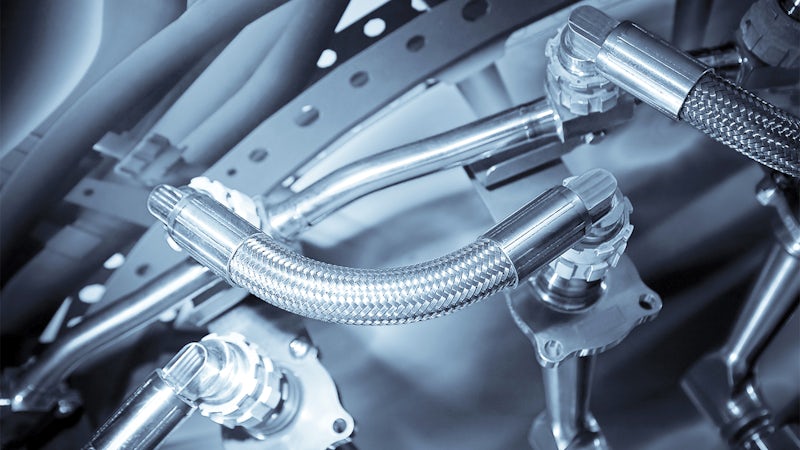

The Parker Hannifin Corporation is one of the world‘s leading diversified manufacturers of motion and control technologies. It provides precision-engineered solutions for a wide variety of commercial, mobile, industrial and aerospace markets. Relying on a strong pool of 60,000 employees worldwide, Parker’s strategy is to achieve outstanding financial performance, premier customer services and profitable growth.

http://www.parker.com- Headquarters:

- Mayfield Heights, United States

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Aerospace & defense, Industrial machinery

Delivering premier customer service

The Parker Hannifin Corporation (Parker) is one of the world’s leading diversified manufacturers of motion and control technologies, providing precision-engineered solutions for a wide variety of automotive, commercial, mobile, industrial and aerospace markets. With 60,000 employees worldwide, Parker’s strategy is to achieve outstanding financial performance along with premier customer service and profitable growth.

Outstanding customer service is a pillar of Parker’s success. All divisions of the organization constantly strive to fulfill ever-escalating customer expectations. Customers today demand components and systems that not only provide high performance, but also improve energy efficiency.

Parker has also recently seen its relationships with long-term customers evolve. More and more vehicle manufacturers and other world-leading original equipment manufacturers (OEMs) expect systems suppliers such as Parker to provide them with the same products and comprehensive service as a system integrator. As a result, Parker must not only provide parts and components to OEMs, but also function as a technology and integration partner.

This trend impacts not only Parker’s strategy, but also the daily work of many engineers. For example, at Parker’s Hydraulic Cartridge Systems division (HCS), the core product engineering group develops new products and assists the quality and operations departments by improving existing products or solving quality issues.

In the early stages of the development process, engineers collaborate with the marketing team to define product specifications and follow up on product development from the design to the validation phases. As a result of recent trends, engineers in the group have been inundated with internal requests. The requests represent frequent, short-term interruptions that distract engineers from their main objective: future product development. The requests come from various internal departments that face immediate issues with their customers. Fast and efficient troubleshooting is required to ensure excellence in customer support.

Solving malfunction problems

For example, the HCS core product engineering group recently responded to a customer’s complaint about what appeared to be a malfunctioning valve. The group performed numerous product simulations and tests over several months, in collaboration with the quality department. However, the analysis could not reveal any particular defect. In all cases, the valve functioned according to its specifications. To find a solution, representatives of the HCS core product engineering group used Simcenter Amesim software, part of the Simcenter portfolio from Siemens Digital Industries Software, to help them understand how the valve interacts with other circuit parts.

First, the engineers modeled the valve using Simcenter Amesim, then performed a sensitivity analysis on the modeled component and compared the analysis results with those of tests performed on the physical component. The correlated results were a 97.5 percent match. The study clearly confirmed that there was no defect in the component. After that, the full customer circuit was modeled, using components from the Simcenter Amesim Hydraulics library. The HCS core product engineering group quickly figured out that the valve was functioning precisely the way it was designed to function.

A systemic circuit issue turned out to have caused the problem. The HCS core product engineering group modified another valve using the Simcenter Amesim model of the circuit. It was quickly done and yielded outstanding results. The malfunction problem was gone. Parker engineers could spot the actual defect in the circuit design, and virtually demonstrate to their customer the validity of their theory. Later on, the HCS core product engineering group performed some real-world tests to confirm the simulated results.

With a traditional engineering approach, it would have taken the engineers several more months to identify the defect. Using Simcenter Amesim, it only took a few days. In addition to saving months of work and a significant amount of money, the analysis also helped improve the company’s relationship with the customer.

Achieving high-precision system engineering

A part or component is designed to fulfill a specified function in a system. A defect in even the smallest component can potentially lead to failures, from reduced systems performance to complete breakdown. High precision is required, not only when designing and validating a component, but also when integrating it into a system’s environment.

Using Simcenter Amesim, Parker engineers can quickly assess how components interact within the entire system. Using Simcenter Amesim helps them reduce the time spent in testing and deliver results more rapidly. Thanks to the model-based approach, engineers can perform analysis at any stage of development, from early design to troubleshooting.

In addition to committing significant time to product innovation, the HCS core product engineering group spends notable time providing customer service. Moreover, Simcenter Amesim can be used as a powerful troubleshooting tool early in the design process to help quickly spot defects and virtually remove them.

The use of system simulation tools, including Simcenter Amesim, continues to spread across Parker divisions. Simcenter Amesim users in the company have been asked to organize internal training sessions with co-workers.

The shift to system simulation has become highly strategic for Parker. Comprehensive and detailed system knowledge is essential to faster and better product innovation.

The trusted model-based approach of Simcenter Amesim accelerates the positioning of Parker as a complete technology and integration partner for advanced manufacturing industries.