Landing gear manufacturer uses Simcenter software to design safe, high-performance products

Siemens Digital Industries Software helps GKN Aerospace Fokker Landing Gear save up to 30 percent of performance and loads development time

GKN Aerospace Fokker Landing Gear

GKN Aerospace is one of the world’s leading multi-technology tier-one aerospace suppliers. As a global company serving the world’s leading aircraft manufacturers, GKN Aerospace develops, builds and supplies an extensive range of advanced aerospace systems, components and technologies for use in aircraft ranging from helicopters and business jets to the most used single-aisle aircraft and the largest passenger planes in the world. Lightweight composites, additive manufacturing, innovative engine systems and smart transparencies help to reduce emissions and weight on the aircraft and enhance passenger comfort. GKN Aerospace is a market leader in aerostructures, engine systems, transparencies and wiring systems, and operates in 14 countries at 54 locations employing approximately 18,000 people.

http://www.gknaerospace.com- Headquarters:

- Helmond, Netherlands

- Products:

- Simcenter Products, Simcenter Amesim

- Industry Sector:

- Aerospace & defense

The time and budget we spend on development has an enormous impact on commercial success.

GKN Aerospace Fokker Landing Gear

Safety and performance at minimum weight

Flying around in enormous mechanical birds has been without question one of the greatest achievements in human history. When talking about planes, most people think of parts such as the wings, the engines, the airframe or the tail. But just like no bird could ever survive without strong legs it can rely on to touch ground safely, a robust and reliable landing gear is among the most vital parts of an aircraft.

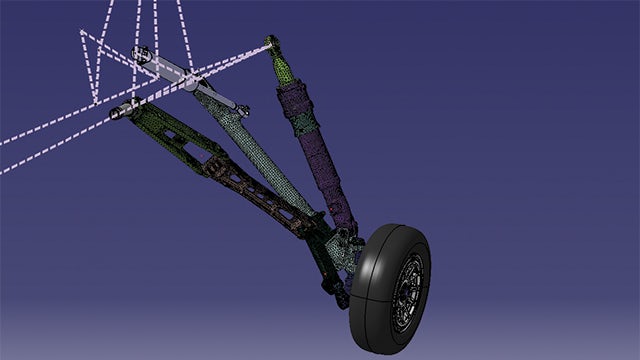

Landing gear designs can come in various shapes and sizes. Because the choice for a certain configuration greatly impacts many overall behavioral aspects of the entire aircraft, the landing gear needs to be developed along with the rest of the structure.

The main purpose of a landing system is obviously to reduce impact loads by absorbing and dissipating kinetic energy. But it also must provide suspension as well as wheel steering and braking while the plane is taxiing on the tarmac. Most landing gear systems, especially for faster aircraft, are retractable to reduce aerodynamic drag during flight. But these are usually heavier and can take up to three percent of the total aircraft weight. Especially for military gear, design engineers must make sure that all fits in a limited volume with prescribed aircraft interfaces.

Reducing weight and volume without compromising operational performance and safety is a real challenge. And as the development shouldn’t delay the design of the overall aircraft, landing gear manufacturers are looking for solutions that help them investigate as many alternatives as possible in the shortest possible time span.

Over 30 years of experience

The engineers at GKN Aerospace Fokker Landing Gear business in Helmond, The Netherlands, master the art of delivering safe, high-performance landing gears to aviation original equipment manufacturers (OEMs). For more than 30 years, specialists have gathered competencies in design, development and production, as well as repair and overhaul, of landing gear systems for helicopters and airplanes. GKN Landing Gear delivers exceptional value to its customers through tailored designs, optimized development processes, rigorous qualification and certification standards, cutting-edge production technologies and maintenance, repair and operations (MRO) capabilities. Among their current programs are prestigious aircraft such as the Lockheed Martin F-35 Lightning II Joint Strike Fighter military airplane and the Boeing Apache AH-64 helicopter. GKN Landing Gear is making large investments in research and development (R&D), aiming to soon deliver the first load-carrying composite parts on a landing gear.

Dr. Bert Verbeek, specialist development engineer dynamics, and Guus Kolster, commercial director at GKN Landing Gear, have been around for many years. They have seen on many occasions how proof of experience has played an essential role in being considered a reliable partner by OEMs. But they also feel that over the last decade the pressure on time and budget has dramatically increased, and notice that the industry has evolved to even tighter schedules. These trends significantly influence product design. “Unlike consumer products, landing gears don’t come in huge sales volumes,” says Kolster. “As a consequence, the time and budget we spend on development has an enormous impact on commercial success. There is little room for trial and error. For this reason, it’s important to have a streamlined process based on accurate upfront simulation, helping us optimize the structure before we build the first prototype.”

Increased credibility and a 30 percent time gain

Providing powerful software tools and delivering efficient simulation solutions are core business objectives of Siemens Digital Industries Software. For many years, the software solutions in the SimcenterTM portfolio have been part of the standard development process at GKN Landing Gear. These include the motion simulation solution from Simcenter portfolio software for 3D multibody dynamics analysis and Simcenter AmesimTM software for 1D multiphysics simulation.

Verbeek was one of the first engineers to begin the successful collaboration between GKN Landing Gear and Siemens. “Before, we had a different software package for 3D multibody simulation of the mechanism, which we had to combine with a lot of user programming for damping models and other systems,” he says. “The process was time-consuming and error-prone. Moreover, it was a real hassle to transfer knowledge to new members in the team, which is greatly improved now by using Simcenter Amesim. We realized that we needed a more professional and streamlined process. That would not only make our lives easier, but it would also increase our credibility and ability to collaborate with industry partners.”

Motion simulation solution from Simcenter portfolio and Simcenter Amesim resonate well in the aviation market, and the market acceptance was certainly one of the crucial arguments in selecting these products. “As landing gear development needs to happen in parallel with the rest of the structure, we have to be able to effectively exchange information and ideas with our partners,” says Verbeek. “Our customers give us the information we need to calculate ground and interface loads, and from our side we give them our models so that they can refine the full aircraft simulation. All this can happen much easier if we work on a similar platform, or at least with software packages that communicate well with each other. Also, when we meet during a project to exchange ideas or preliminary results, it increases our credibility if we show that we have been using a professional solution with a solid reputation, and if we can present data and displays in a format that looks familiar.”

Deploying a new solution is never easy. It takes training and effort to adapt users to a new graphical user interface (GUI), initiate a set of models and build databases with validated components. “The support professionals from Siemens Digital Industries Software helped us with the daily use of the software,” explains Verbeek. “In addition, we do small projects with their R&D team to improve the modeling accuracy of certain parts.”

Along with the new software environment, the effective collaboration with Siemens Digital Industries Software engineers resulted in a spectacular time gain. “When we compare the current process using Simcenter solutions to the previous one, we can for certain say that we saved up to 30 percent of time,” confirms Verbeek. “We could use this time to further validate and improve physical descriptions in our models and to do additional simulations. We are working towards parametric 3D models for most of the important landing gear configurations as well as parametric 1D libraries for shock absorbers and tires.”

Automating the optimization process

At present the engineers have the entire simulation process installed and in smooth operation, including interfaces between various software, as well as parametric models and optimization loops for performance, weight and cost. Now the company wants to take it to the next level, and automate the process. To do so, they are again collaborating with Siemens Digital Industries Software. “First of all, we are further extending and improving our libraries,” says Verbeek. “We are creating additional 1D models for shock absorbers, as well as 3D multibody models and computer-aided design (CAD) parts. And we are looking into new shimmy modeling options. And secondly, we are having scripts created to run the entire simulation process without user interaction. This is yet another project that we have started with Siemens Digital Industries Software experts.”

The engineers are convinced that this additional work will once more boost their productivity. “By moving the original process to a professional software environment, we had already saved about 30 percent of time, but we expect even more from this automation,” Verbeek says. “In the current process we still actually evaluate just one configuration that we choose upfront, as we don’t have time to build several more. This means that we still have to rely a lot on intuition and experience. We are sure that this situation will change when we have these automation scripts.”

Kolster is also very optimistic about the outcome. “Considering that we have about three or four fundamentally different 3D layouts that we can each combine with a few shock absorber models, my rough estimation is that after automation we could investigate about 15 to 20 design layouts within the same time frame,” he says.

We realized that we needed a more professional and streamlined process. That would not only make our lives easier, but it would also increase our credibility and ability to collaborate with industry partners.

GKN Aerospace Fokker Landing Gear