Manufacturer uses NX CAM to reduce costs of producing precision aerospace parts by 33 to 50 percent

Siemens Digital Industries Software solution enables Akaba Seisakujyo to support a wider variety of products

Akaba Seisakujyo

Akaba Seisakujyo is a diversified solutions provider of precision computer numerical control (CNC) machined components for multiple industries. For over 50 years, Akaba Seisakujyo has supported hightech companies involved in the manufacture of semiconductors, thin film transistor-liquid crystal displays (TFT-LCD), next-generation energy products, railcars and aerospace.

http://www.akb-ss.com- Headquarters:

- Iida City, Nagano, Japan

- Products:

- NX, NX CAD, NX CAM

- Industry Sector:

- Aerospace & defense

It is pointless to have great ideas if you cannot implement. NX enables us to realize innovation – quickly, easily and cost-effectively.

Akaba Seisakujyo

Delivering precision machining

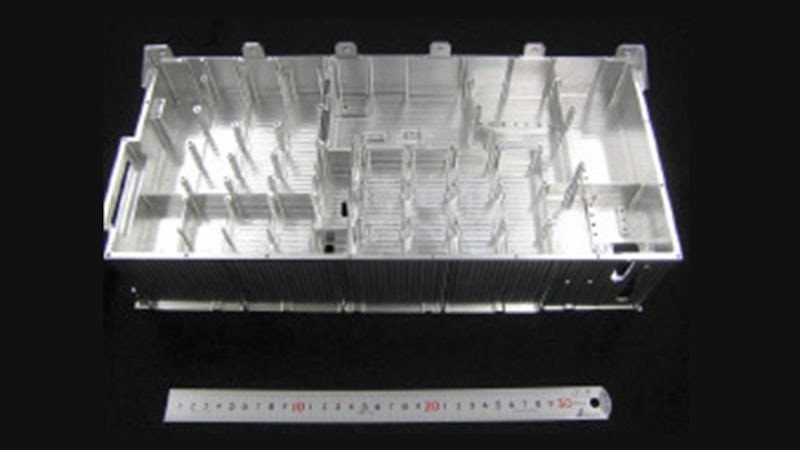

Located in Iida City, Nagano Prefecture in the center of Japan, Akaba Seisakujyo started out as a manufacturer of molds, but changed course to focus on machining aerospace-related precision components after the market shake-up in 2008. Currently, the company is using NX™ software and 5-axis machine tools to produce large-scale precision parts on a daily basis.

President and CEO Toru Akaba explains how the company adapted to the changing business climate: “We were providing contract manufacturing of aerospace parts from the beginning, but considering market dynamics, we restructured our aerospace emphasis and added railway instrument components. We began manufacturing components for domestic satellites rather than aircraft. At first, things were really tough on the factory floor. At that time, we used CAM (computer-aided manufacturing) solutions from another vendor.”

Akaba Seisakujyo first implemented computer-aided design (CAD) about 25 years ago, and a CAM solution about 20 years ago. The company carried out its work without relying on CAD by using many cutting machines. At that time, CAD was used less than 10 percent of the time, but after the company entered the aerospace instrument field, the demand for digital tools gradually increased. Today, CAD and CAM have become indispensable with the large number of orders for the limited manufacture of a wide variety of products.

“The products we produced were basically limited to flat items; mainly hole punching at the beginning.” says Akaba. “However, as machined products gradually grew more complicated, programming with the previous CAM system became time-consuming and inefficient. To improve our productivity, we decided to implement a more advanced CAM solution.”

Optimizing manufacturing operations

The company soon recognized NX from product lifecycle management (PLM) specialist Siemens Digital Industries Software as the solution to best meet its requirements. Hideshi Matsushita, production director at Akaba Seisakujyo, recalls what was happening on the factory floor at that time: “We knew that we had to find a way to change our business focus and began seeking new ideas. For example, we considered not only aerospace, but also fields such as nuclear power and railways, initially starting with transportation infrastructure and railroad cars. We contacted a company that focused mainly on railways. In talking with them, we learned that without an integrated CAD/CAM system to handle the 3D models, we would not be able to support effective data handling and rapid design changes.

“An important thing we learned from the railway company is that using NX would result in a significant programming advantage. We began to seriously consider CAD/ CAM solutions. It quickly became obvious that it would be easier for us to expand into the railway field if we use the same CAD system.”

Ultimately, an order for railway car components was the catalyst for choosing NX.

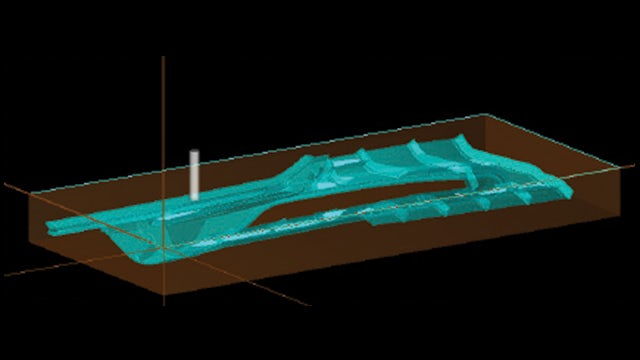

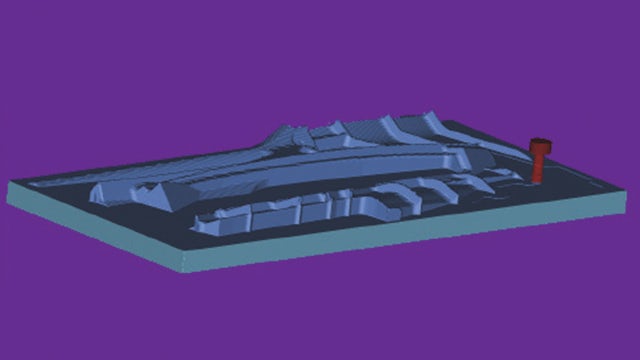

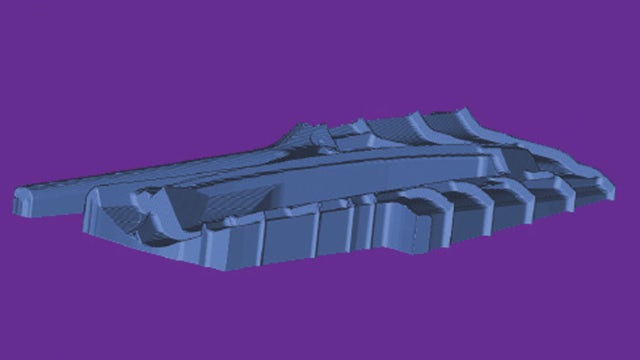

Matsushita discusses the challenges: “Take the railway car of bullet trains as an example. The streamlined section at the front of bullet trains is machined from a block of aluminum. The front body structure is analyzed with a wind tunnel and other tests, and the complex shapes of the railway car can be accurately produced only with CNC machining.

“In addition, it is necessary to precisely define and machine the cut regions. That was difficult with the previous CAM system. Without the power of integrated CAD and CAM, you cannot efficiently create G-code for an NC (numerical control) program.” Matsushita notes that it would have been very ineffective to program complex parts without using the same software system as the customer.

“More than anything, NX provides comprehensive NC programming capabilities,” says Matsushita. “We evaluated various CAD/CAM solutions, but it was NX and its CAD capabilities that enable us to effectively handle large-scale model data. We can now easily use assemblies from customers. This significantly improves our collaboration with our clients, and the advanced NX CAM functions help us streamline and optimize our manufacturing process – from planning to production.”

Akaba Seisakujyo was able to set up and begin manufacturing its first product only three weeks after implementing NX. “During this period, the help from the local Siemens Digital Industries Software partner was critical,” says Matsushita. “The online support provided by Information Services International-Dentsu, Ltd. (ISID) was very extensive. Quickly, we were able to use the full power of the advanced functionality in NX.

“ISID provided extensive technical support to every member of our team. We could not have delivered our product within three weeks without their help. The support we receive from ISID engineers is remarkable.”

Reaping the rewards of NX

NX was implemented in 2011, so Akaba Seisakujyo has had a good chance to assess its ease-of-use and results. “First, using NX, we were able to reduce the costs of medium- and large-size, 5-axis processed aluminum goods by 33 to 50 percent compared to using our previous CAM solution,” says Matsushita. “For example, the preparation for programming one of the parts used to take 90 minutes. With NX CAM, we reduced it to 30 minutes, or onethird of the time.

“In addition, we expanded the types of product orders we can receive, because we can evaluate the optimum toolpath and requirements for various sizes and levels of precision, from small, palm-sized products to large-sized products greater than 2.5 meters using 5-axis programming.

“NX enables us to effectively address advanced requirements for the most complex parts. We can use the powerful drafting and assembly functions for our specific needs. With the advanced NC programming capabilities of NX CAM, we can easily program different types of parts used in different industries. This flexibility enables us to get more orders.

“We have been using NX now for three years. Going forward, we want to implement more programming automation. We believe that we can further improve our productivity by using predefined templates. For example, the shape of railway car parts doesn’t change all that much, so we can optimize the programming by using templates to machine similar parts.”

President and CEO Akaba concludes, “It is pointless to have great ideas if you cannot implement. NX enables us to realize innovation – quickly, easily and cost-effectively.”

More than anything, NX provides comprehensive NC programming capabilities. We evaluated various CAD/ CAM solutions, but it was NX and its CAD capabilities that enable us to effectively handle large-scale model data. We can now easily use assemblies from customers. This significantly improves our collaboration with our clients, and the advanced NX CAM functions help us streamline and optimize our manufacturing process – from planning to production.

Akaba Seisakujyo