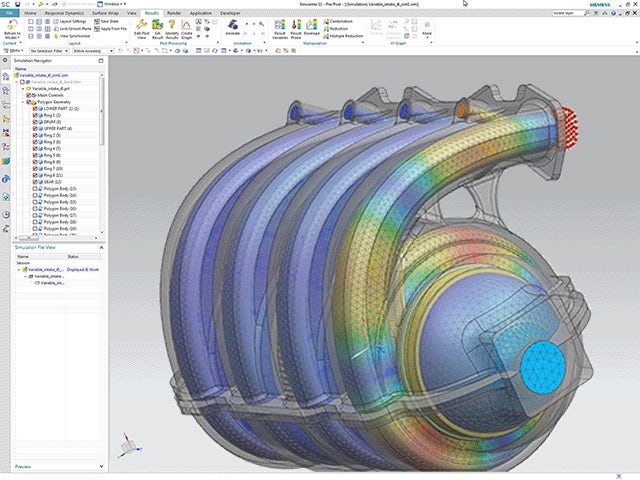

La comprensione e la fornitura di prestazioni tra domini richiedono soluzioni di simulazione e test che possano essere implementate in tutte le fasi di sviluppo e in tutti i domini di prestazioni e fisica. Inoltre, queste attività devono essere collegate, non condotte in modo indipendente, per catturare i fenomeni multifisici del mondo reale e bilanciare gli attributi in conflitto. Simcenter offre un portafoglio integrato di soluzioni di simulazione predittiva, test ed esplorazione della progettazione all'avanguardia che coprono tutte le fasi del processo di sviluppo del prodotto per risolvere i problemi più complessi dell'ingegneria e possono contribuire a trasformare l'ingegneria aumentando la produttività e favorendo l'innovazione.

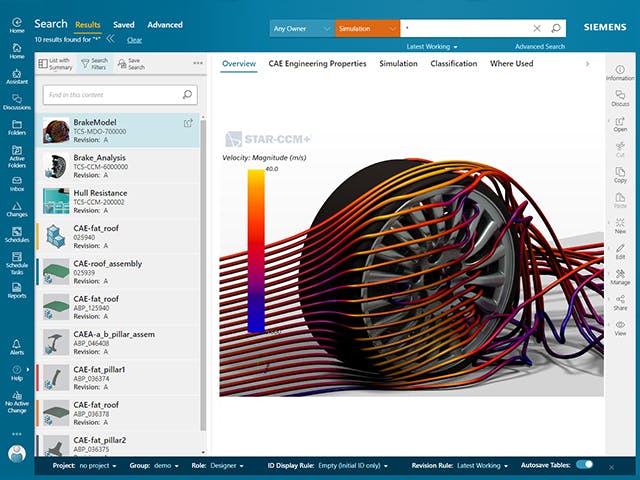

La simulazione e il test non possono più essere visti come attività a compartimenti stagni. Il gemello digitale offre valore durante l'intero ciclo di vita e la sua evoluzione deve essere gestita per la tracciabilità e l'impatto del cambiamento. Ciò è possibile solo fornendo simulazioni e test come parte di un'iniziativa globale di sviluppo del prodotto digitale. Siemens Xcelerator sfuma i confini tra domini ingegneristici come quello elettrico, meccanico e software, mentre le soluzioni di simulazione e test Simcenter completano le soluzioni Siemens Xcelerator nelle fasi di progettazione, realizzazione e ottimizzazione del ciclo di vita.

Nel percorso verso la trasformazione digitale, le aziende hanno bisogno di partner affidabili con le risorse per guidare continuamente l'innovazione negli strumenti e nelle applicazioni. Siemens spende in modo significativo in ricerca e sviluppo, fa leva su partnership con aziende affermate in aree adiacenti e investe in startup che dispongono delle tecnologie che potrebbero trasformare il business in futuro. Tutto ciò garantisce un flusso costante di innovazioni che possono aiutare i nostri clienti a rimanere all'avanguardia e a realizzare i vantaggi della digitalizzazione più velocemente rispetto ai loro concorrenti. I servizi di progettazione e consulenza di Simcenter forniscono conoscenze approfondite, strutture, risorse e competenze per accelerare la trasformazione dei processi di progettazione e il conseguente ritorno sugli investimenti.