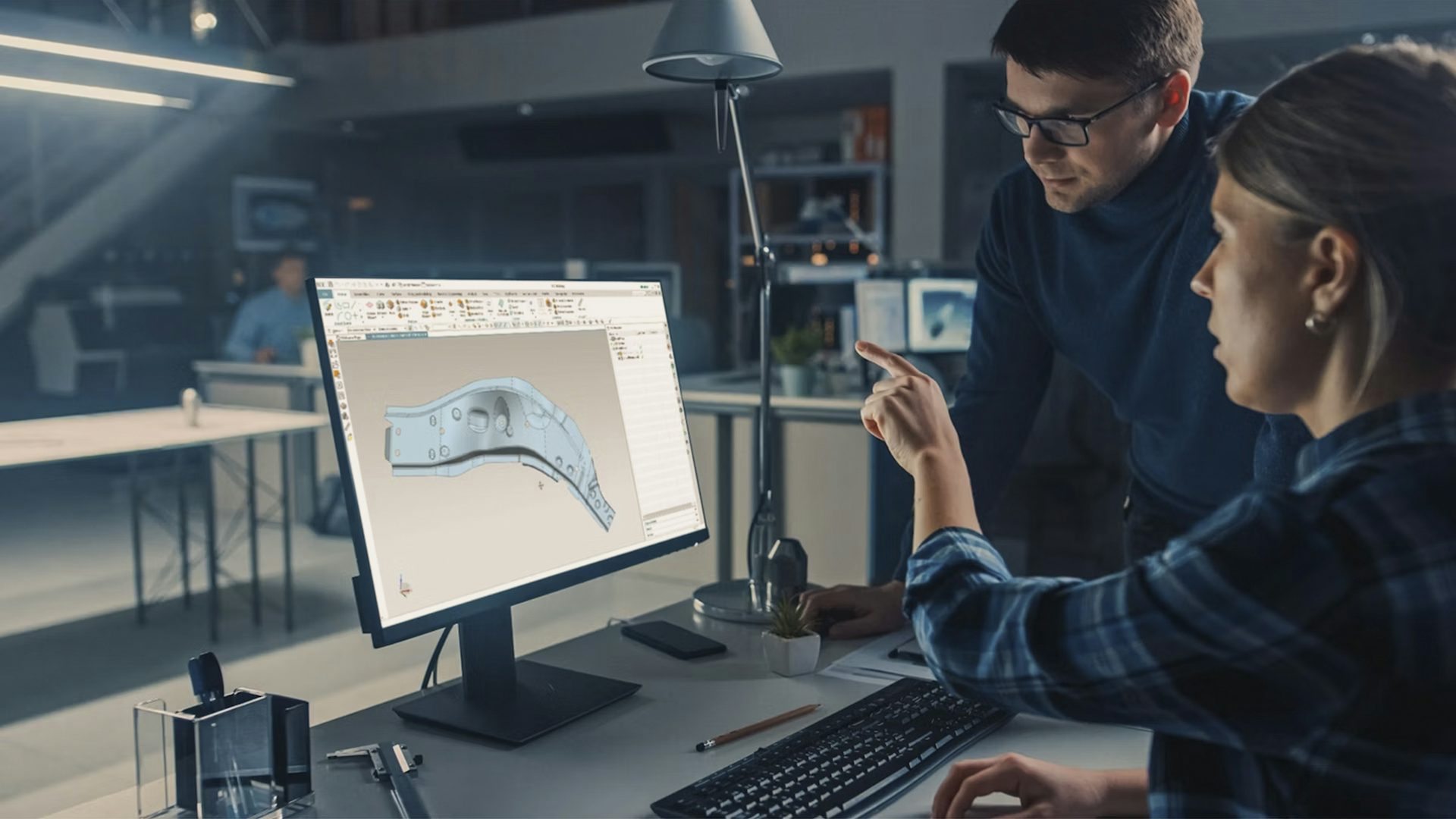

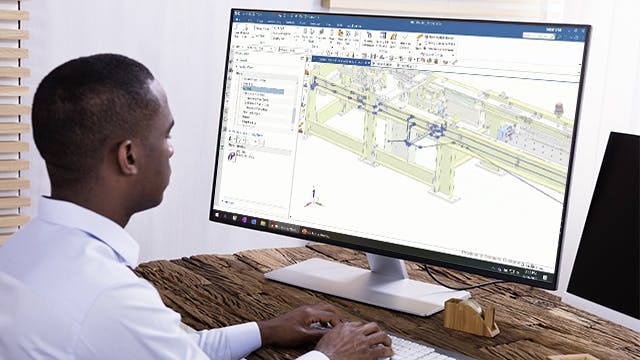

I clienti richiedono prodotti complessi, di alta qualità e sostenibili che vengano consegnati rapidamente. Per rimanere competitivi, è necessario sviluppare e rilasciare progetti innovativi che soddisfino le esigenze di un mercato in evoluzione in meno tempo, con una qualità premium, con meno problemi e a prezzi competitivi.

Il problema nella progettazione del prodotto oggi è che molte aziende utilizzano ancora sistemi di progettazione legacy scollegati tra loro che non supportano un approccio olistico alla progettazione del prodotto di nuova generazione. Per avere successo, la progettazione deve essere completamente integrata con la simulazione, la validazione, la produzione e il resto del processo di sviluppo del prodotto.

.jpg?auto=format,compress&w=640&q=60)

.jpg?auto=format,compress&w=640&q=60)