Come è possibile produrre componenti altamente precisi, di alta qualità, personalizzati e sostenibili in tempo e su larga scala, migliorando al contempo la produttività e la redditività complessive?

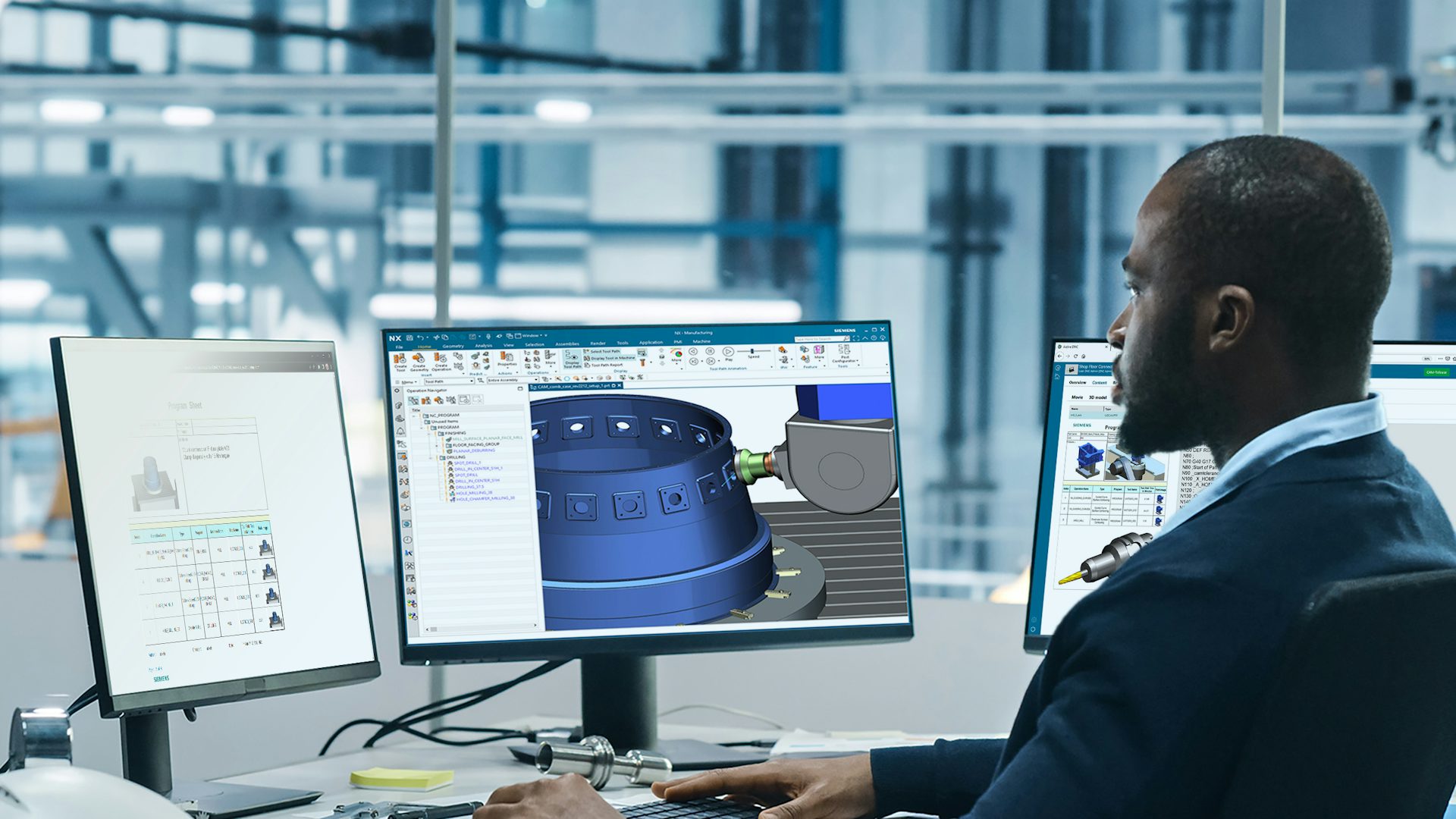

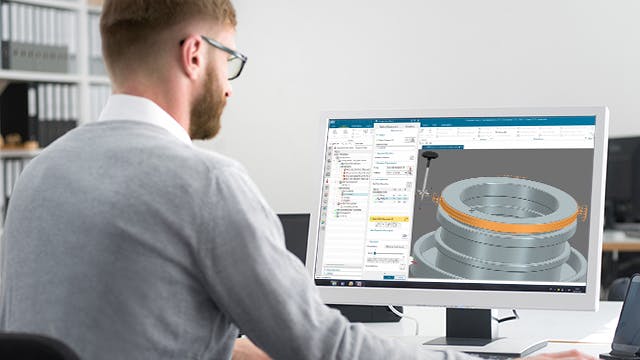

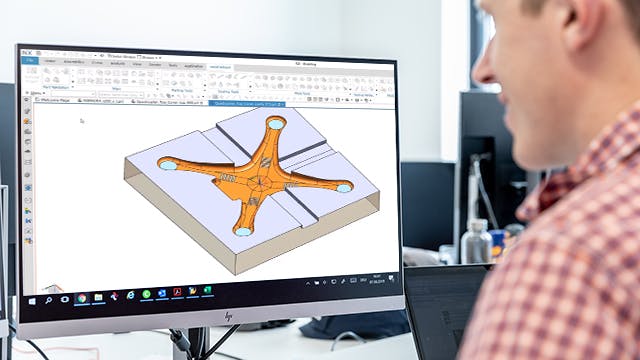

Implementa una soluzione software integrata per la produzione di utensili e parti. Automatizza e connetti progettazione, produzione e operazioni nell'officina meccanica digitale utilizzando una suite collaudata e potente di strumenti e soluzioni software.