Quali strategie possono adottare gli ingegneri aerospaziali per accelerare le tempistiche di progettazione, raggiungere gli obiettivi prestazionali e garantire un'introduzione in servizio senza intoppi?

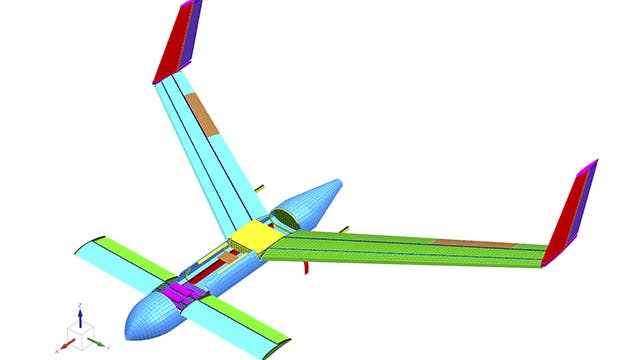

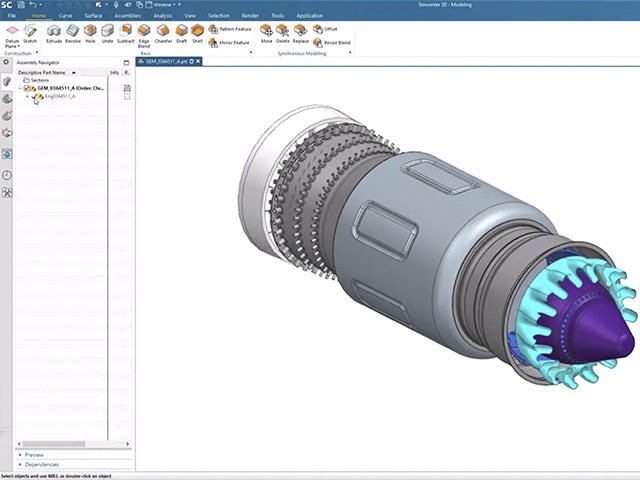

Implementa una strategia integrata di simulazione e test e utilizza il software di simulazione aerospaziale per guidare la trasformazione digitale, abbattere i silos tra le discipline e ottenere informazioni tempestive sulle prestazioni del prodotto per le strutture, l'aerodinamica, l'integrazione virtuale e altro ancora.