L'industrie automobile connaît des bouleversements avec l'adoption des systèmes avancés d'aide à la conduite (ADAS) et l'électrification des véhicules. Les équipementiers occidentaux doivent répondre aux exigences actuelles et se préparer pour l'avenir à l'aide de nouvelles technologies innovantes. Afin de réduire les délais et les coûts de conception, ils adoptent la conception basée sur la simulation. Pour réussir, ils ont besoin de méthodes rapides et précises afin de saisir les conditions d'exploitation réelles.

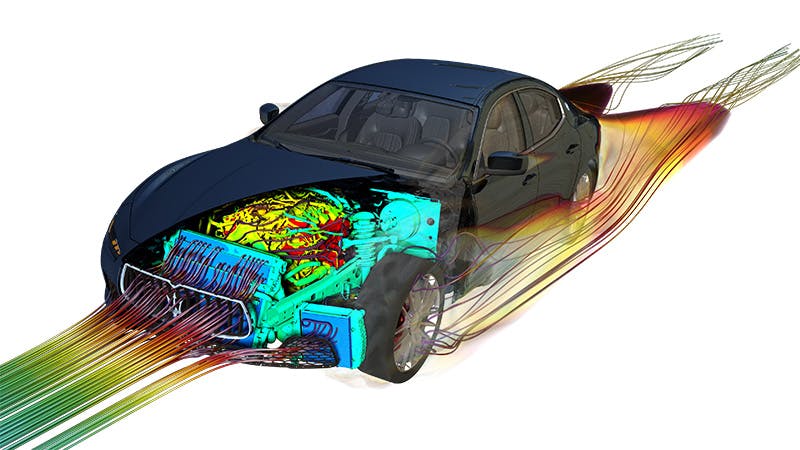

La protection thermique et l'aérodynamique sont deux critères de conception essentiels pour minimiser la consommation d'énergie et améliorer les performances des véhicules. Ce webinaire explique comment les équipementiers peuvent réaliser en quelques jours une simulation qui prenait auparavant des semaines, et comment le flux de travail complet, de la conception assistée par ordinateur (CAO) aux résultats, peut être effectué en quelques heures seulement.

Dans la première moitié, nous montrerons le flux de travail réel pour la configuration et l’exécution de la simulation. Dans la seconde partie, nous vous présenterons comment les différents équipementiers personnalisent et adoptent ce processus.

Les points abordés :

- Comment mettre en place un flux de travail pour la protection thermique

- Gestion automatisée des données : réduction du délai de construction et augmentation du temps d'analyse

- Multi-physique tout-en-un : interactions de systèmes multiples dans une seule simulation

- Délai d'exécution rapide : itération plus facile pour innover plus rapidement

- Protection thermique dans la production

- Ligne directrice générale pour fournir une automatisation puissante avec un délai d'exécution rapide

- Importation personnalisée de milliers de composants pour maximiser le transfert d'informations

- Automatisation de cycles d'entraînement complexes basés sur des changements induits par des événements

- Automatisation du post-traitement pour détecter les problèmes plus rapidement

- Ajout d'une interface personnalisée pour simplifier le flux de travail et permettre aux ingénieurs de se concentrer sur la conception et non sur le processus

À propos des intervenants

Daniel Steen

Consultant en solutions, Simcenter 3D Fluids Center of Excellence

Daniel est consultant en solutions pour le logiciel de dynamique des fluides Simcenter. Après une formation d'ingénierie aéronautique, Dan a rejoint CD-adapco (aujourd'hui Siemens) en 2015 pour aider les principaux fabricants américains d'automobiles et d'équipements lourds à utiliser Simcenter STAR-CCM+ pour les simulations de gestion thermique des véhicules.

Frederick Ross

Directeur, solutions Simcenter pour l'automobile et les transports

Frederick a débuté sa carrière chez CD-adapco en 1989, qui a été racheté en 2016 par Siemens. Il a acquis une grande expérience en travaillant avec des clients sur des applications telles que la protection thermique des véhicules, l'aérodynamique et le confort thermique des passagers. Il est directement intervenu dans les processus de développement permettant l'automatisation de la simulation de véhicules virtuels, de la CAO aux résultats. Frederick travaille actuellement à la rationalisation des processus internes pour les clients avec l'équipe de gestion de produit de Simcenter STAR-CCM+.

Sunil Karri

Responsable de programme

Sunil Karri est un responsable de programme expérimenté au sein de l'équipe Siemens Engineering and Consulting. Il apporte son expertise dans plusieurs applications de la CFD, notamment l'aérodynamique, la gestion thermique et les écoulements multiphasiques. Il a travaillé en étroite collaboration avec de nombreuses entreprises du secteur automobile pour élaborer des feuilles de route stratégiques afin d'obtenir des capacités de simulation de gestion thermique à différents niveaux de fidélité. Il a supervisé le développement et le déploiement des meilleures pratiques de gestion thermique des véhicules en production grâce à des solutions de flux de travail personnalisées qui ont permis d'accélérer la productivité sur les sites des clients. Il a obtenu un Master en ingénierie mécanique à l'université du Kansas, où il s'est spécialisé dans la mécanique des fluides et les méthodes numériques.